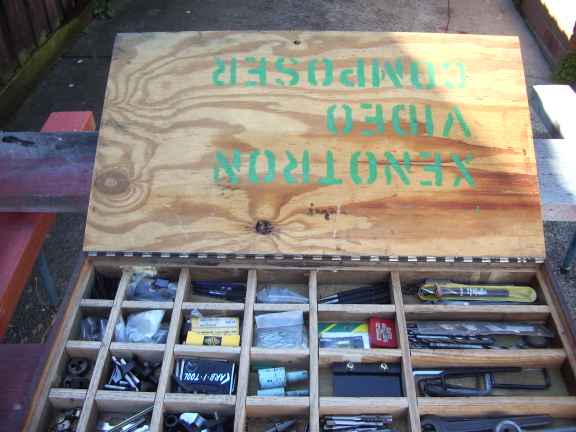

A

small tool chest

a woodworking project

suitable for Triton Work Centre

This small tool chest was one of my very first Triton projects.

The wood for the sides and internal dividers was milled from

some

extremely hard and seasoned hardwood that once was a tabletop. The

timber was extremely hard and was only tractable with TCT tipped tools.

I did not own a router at the time this was constructed so all rebates

were cut on the Triton.

The bottom and the top lid was heavy 5 ply salvaged from an Xenotron

XVC2 Video composer case. (I used to work for Xenotron and

free plywood

was one of the many perks) I cut out this segment of sheet for old

times sake.

The lid is attached with a strip of brass piano hinge, one of the most

usefull inventions to the would be cabinet maker. Piano hinge

strip takes away all the tedious measuring, the need for precision, and

rebate cutting that normal hinges require. Piano hinge is also

immensely strong when used in long lengths. It is about the same cost

as good quality brass hinges. Never ever use steel hinges on

your

precision cabinet work, brass lasts forever. I am vain enough to hope

that some of my work lasts a long time.

The outcome was a very serviceable small tool case that has provided

over twenty years of service.

Project cost is determined only by cost of metal parts, latch and

hinge. Wood was all recovered scrap. Time taken was

one

weekend.

Only thing that I would have done differantly is to have made it about

twice as deep.

home