Fixing an EPSON CX-3700 ink jet printer.

by Ralph Klimek November 2010

Abstract:

An account of an attempted repair of an EPSON CX-3700 ink jet printer with a clogged nozzle.

Keywords : 3700 EPSON ink jet printer, clogged nozzle, disassembly hints and advice.

I

have long been very fond of Epson printers. This is because they

are the only printer maker that does not charge punitively for ink. The

prices for branded ink are not that much greater than clone inks, and

given the potential for harm from the clones, I still like to buy

genuine branded inks. However, notwithstanding that, the time

came when the cyan nozzles on my CX3700 became blocked and the

built in cleaning procedure did not succeed in clearing the blockage.

There was no other option then to proceed to attempt to clear the

blockage manually or the printer would have to be discarded. It

has allready provided two years of good service, so maybe some more

life was possible.

For some strange reason, the service manuals

for these products are extremely difficult to find on the web.

Eventually I found an obscure site in Russia for where I found the

actual service manual. I needed this for instructions for

dissassembly. There are a few simple tricks required to seperate

the scanner unit from the main printer body without causing

damage to both.

The Epson ink jet systems generally

use a water soluble ink and seperate ink tanks. The printing

nozzle assembly is seperate and is expected to endure for the life of

the printer. The nozzle holes are very small. The inbuilt

cleaning mechanism consists of a rubber blade that wipes the

ceramic nozzle plate and a vacuum pump that draws ink through the print

head from the ink tanks. The pumped ink flow is expected to clear

most blockages, and will do so for a couple of years. No mechanism is

perfect, and neither is this one. Eventually coagulated ink accumulates

on the ceramic nozzle holes which no amount of "cleaning" can shift.

I have successfully rejuvenated Epson printers in the past.

The method requires the dissasembly of the print head and the

freeing up of the nozzle plate. It is not allways clear how to do

this. The cheap printers are "progessively assembled" which means that

many things must be removed in sequence.

The liberated nozzle

plate may be soaked in undiluted plain old green dishwashing liquid for

about 24 hours. This will clear nearly all blockages, even those caused

by a completely dried out printer that has been idle for years. The

nozzle plate should be thoroughly rinsed in clean tap water after the

soaking and reassembled. It is possible to reuse the old ink

tanks if they are still mostly full. There is a gotcha. Do not

even power up the printer without the ink tanks in place. The

printer firmware reads and writes a serial EPROM on the ink tanks ink

usage information. If the printer is power cycled without ink tanks in

place the firmware can be irreversibly confused and will throw a

"general error". This is mostly not recoverable. ( I learned this

the hard way !)

DO NOT USE solvents ! (metholated spirits, acetone, kerosene etc. These will destroy the printhead!)

The

ink tanks can be reused, only if air does not enter them from the

needle hold. When you remove them immediately seal the needle hole with

cling wrap and store them with the needle hole down.

Re-assemble the printer , insert your recovered ink tanks and only then re-apply power. All should be good !

The

trick to dissasemble models with the built in scanner unit is to start

with the left hand hinge. There is a snap in cover plate below

this hinge. Remove it first. This exposes the 3 cables going to

the scanner unit. Carefully unplug these and you will see a small self

tap screw that secures the scanner hinge leg in place. Remove this

screw, and the screw that only secure the right hand side hinge foot.

The scanner unit now can be gently lifted clear of the printer body.

If it seems hard or tricky, just remember that an untrained

agricultural migrant worker was able to assemble it with nothing more

than a worn out screwdriver ! You can then remove the top cover

molding which exposes the printer carriage assembly. Do not

force any movement of the carriage, there are plastic cams that lock

the carriage and nozzle plate over a rubber cap that is designed to

prevent the nozzle plate from drying out. If you are carefully,

there is a white plastic cam between the ink tank holders and the

rear metal work that can be depressed to release the carriage.

The nozzle plate can be removed without moving the carriage of its rest

position.

The one thing to remember when dis-assembling these

things is this: If you are using too much brute force, you are doing it

wrong ! Screws and push tabs can be very cunningly hidden ! Look for

them !

Remove and store the ink tanks as advised. Remove

the nozzle plate from above by removing some screws and carefully

detach the ribbon cable.

Assembly is the reverse of the above.

Try to keep the nozzle capping sponges moist during this

operation, I use a damp rag.

Make sure that the carriage guide

plates and axle are clean of rubbish and lightly greased. Many printers

are discarded only because the carriage assembly binds to the axle due

to paper dust and dried out oil. These can be cleaned up with

kerosene, but after this apply just a little machine oil.

The

printer can be reused, however you must first run the nozzle cleaning

program, this will charge the nozzle plate with ink and blow out any

remaining detergent.

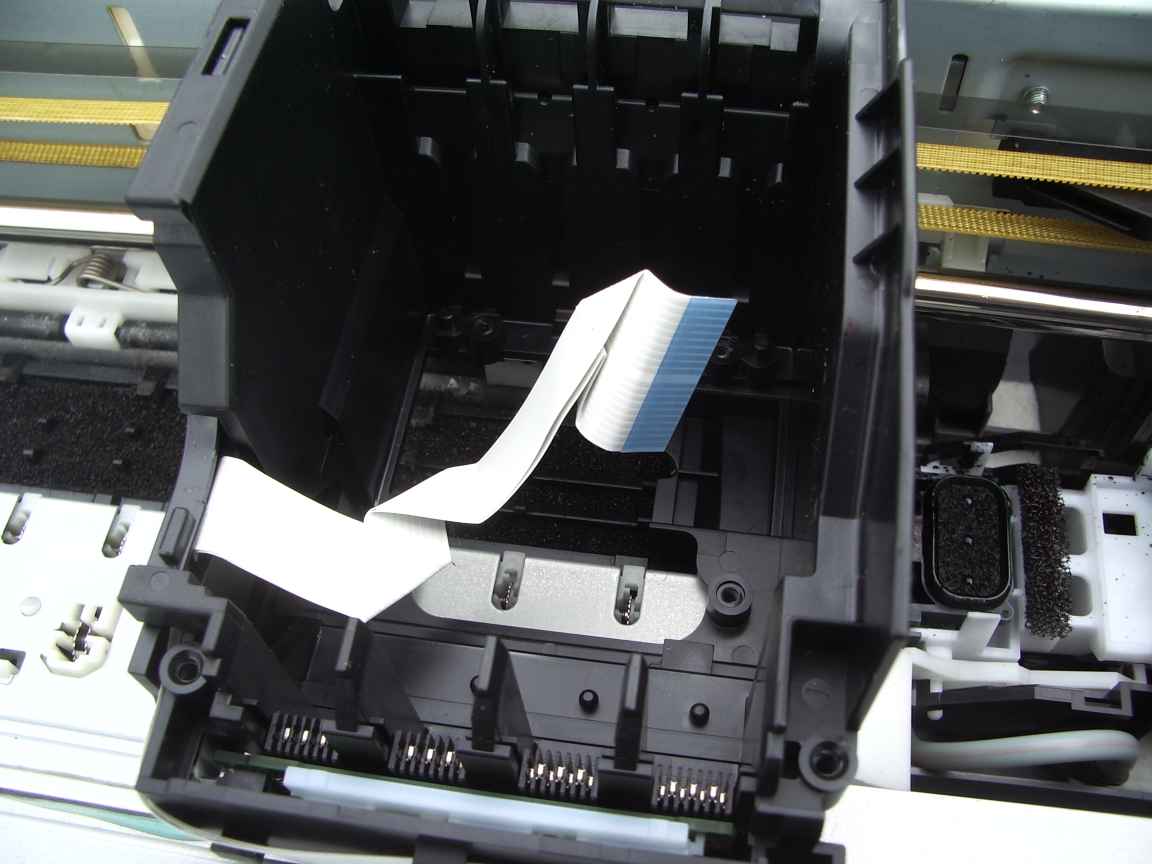

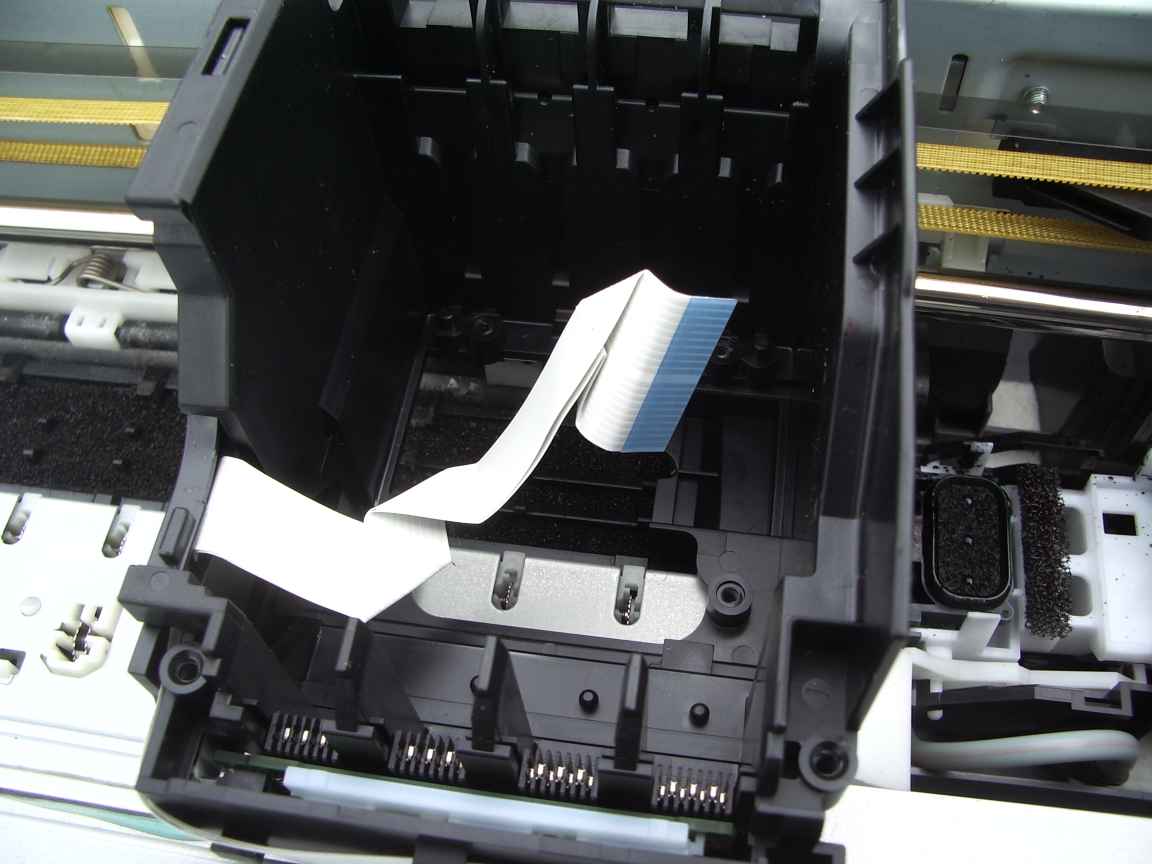

When you are removing these small

assemblies take care with the flat ribbon cables. They have been

carefully folded to fit and relieve mechanical stresses in printer

operation so be carefully to note and maintain the folds.

The

CX3700 service manual can be obtained by a google search, limit the

search to "site:.ru" ( that is , just search for Russian sites !)

otherwise you just get a million ebay and junk site references. I

cannot provide the manual myself due to copyright restrictions and it

is too big to go through email. The manual didnt say more than I am

repeating here but I did find it usefully for hints on the correct

dis-assembly method. Most other faults really cannot be repaired.

I

am puzzled as to why Epson cannot provide the service manuals on their

corporate web sites as they do provide user manuals and drivers. I am

sure you would agree with me that provision of the service manual would

make it a more attractive as a purchasing option.

This

print

head cleaning method IS NOT recommended by Epson. Do this only as

a last resort and only on a printer that you were about to discard.

If after this procedure you get a "general error" indicated by

all front panel lights flashing and a windows driver check box, just

throw the thing away and buy a new one. It is extremely difficult

to determine the cause as the printer firmware will not tell you what

triggered it.

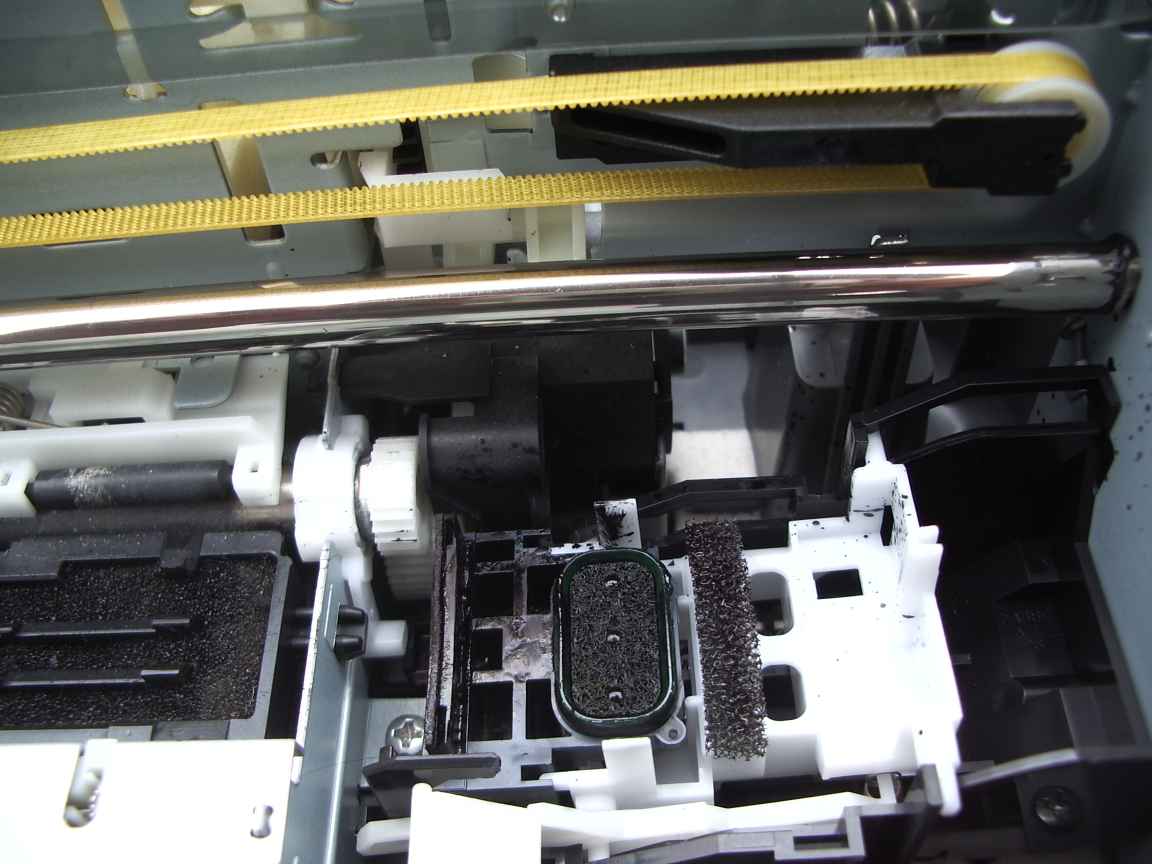

|  |  |

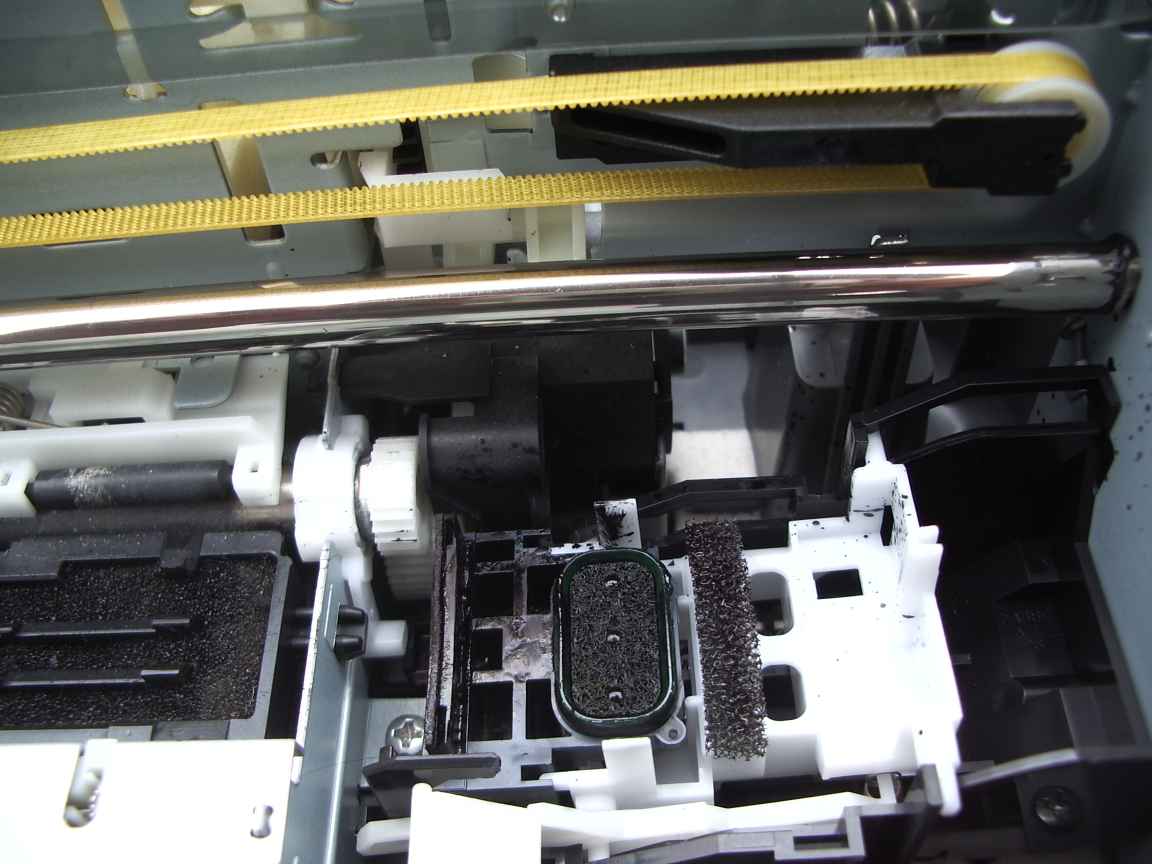

| the carriage has been freed to move after the scanner unit, top cover and control panel have been removed | visible

here is the rubber wiper blade and the ellipsoidal cap. This cap

engages with the nozzle plate to stop it drying out . Just behind

the timing belt you can see a white plastic tab. gently depress this to

release the carriage and allow the carriage to slide freely. Do not use

excessive force here | The white rubber hose goes to a

little vacuum pump. It applies gentle suction to the head cap. It

is this which performs the ink charging and "unclogging". The rubber cap must make good contact with the nozzle plate. |

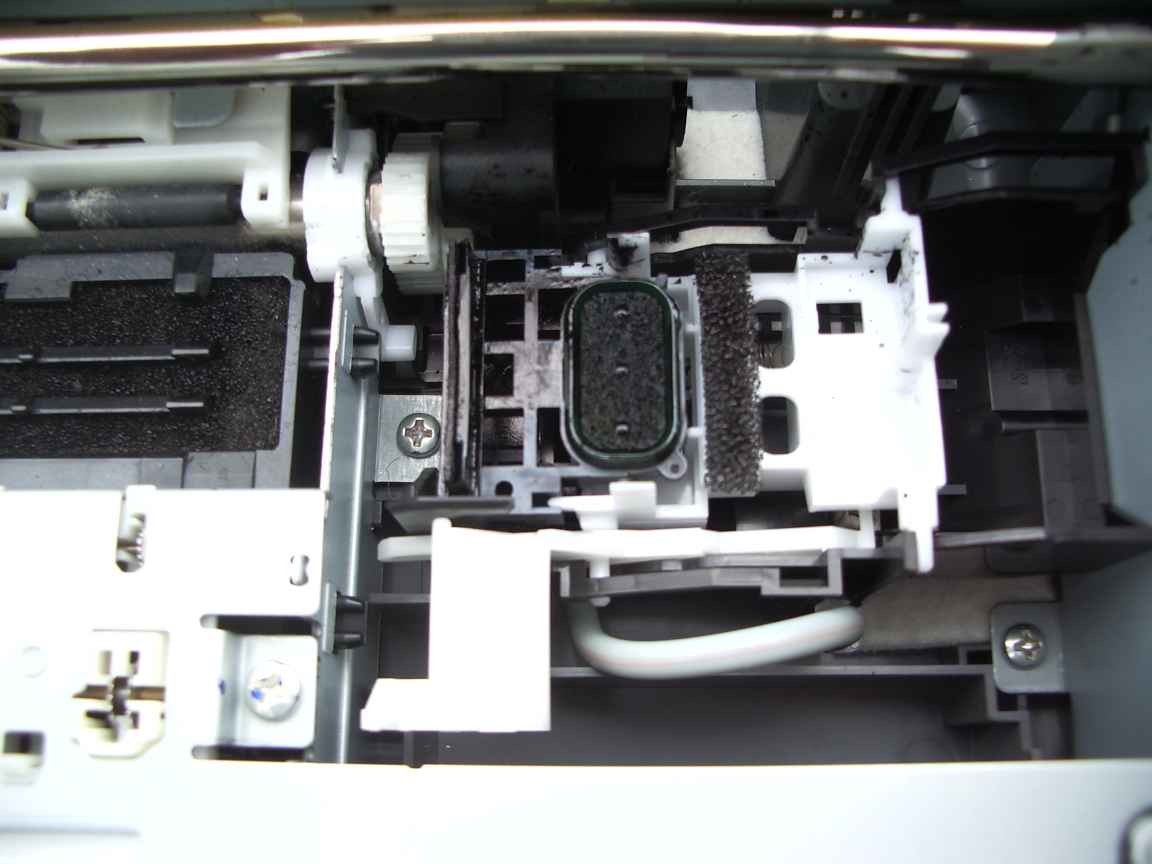

|  |  |

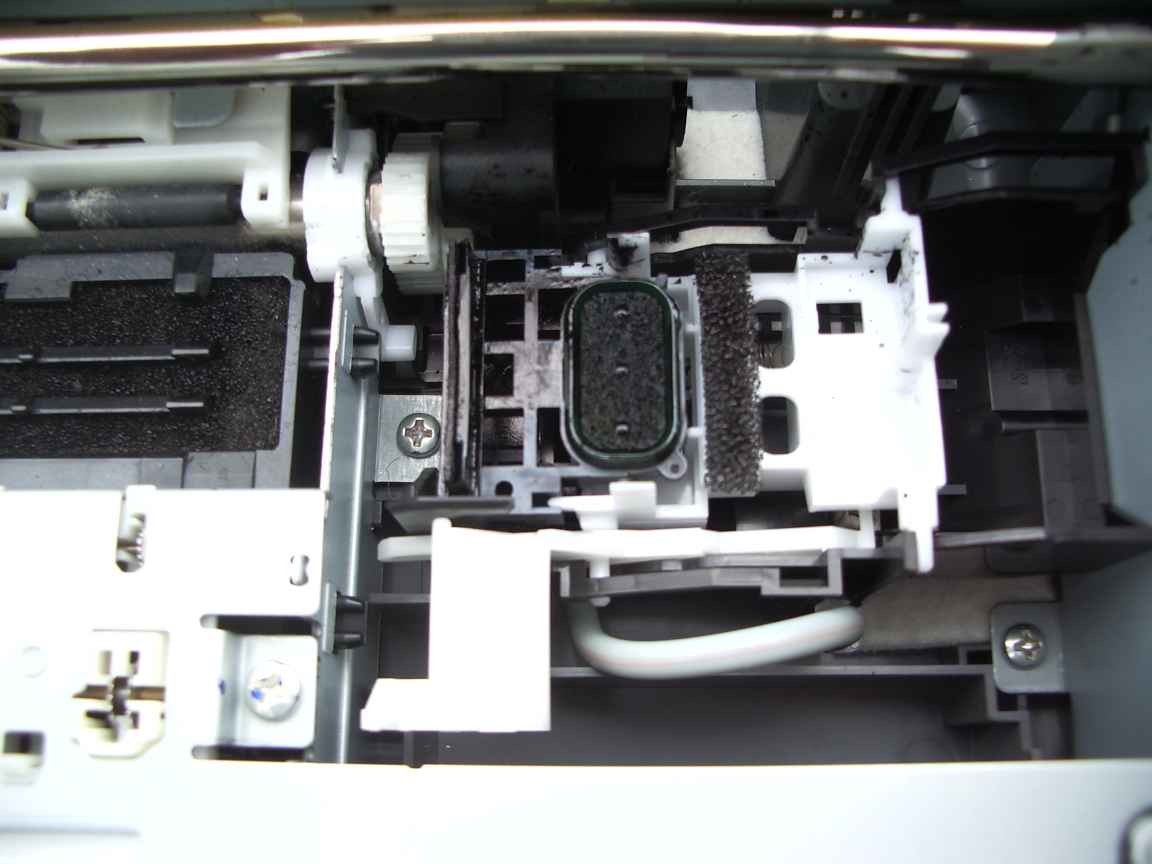

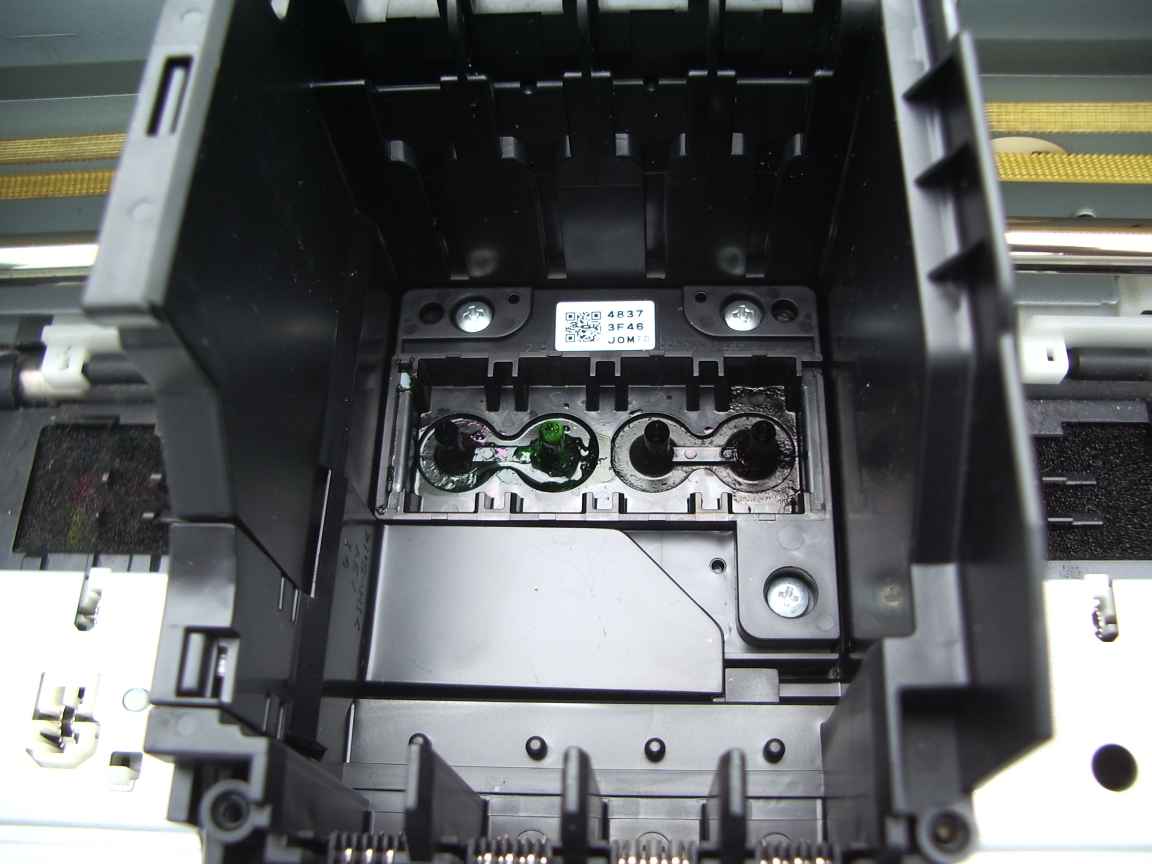

| carriage with ink tanks removed. The four needles push upwards through the shipping seals of the ink tanks | unclip

the plastic cover that shields the ribbon cable. Remove 4 screws

holding the nozzle plate. Remove the nozzle plate and take care to

preserve the ribbon cable and the folds. | the freed nozzle plate. Act quickly, do not permit the nozzle plate to dry out. |

|  |  |

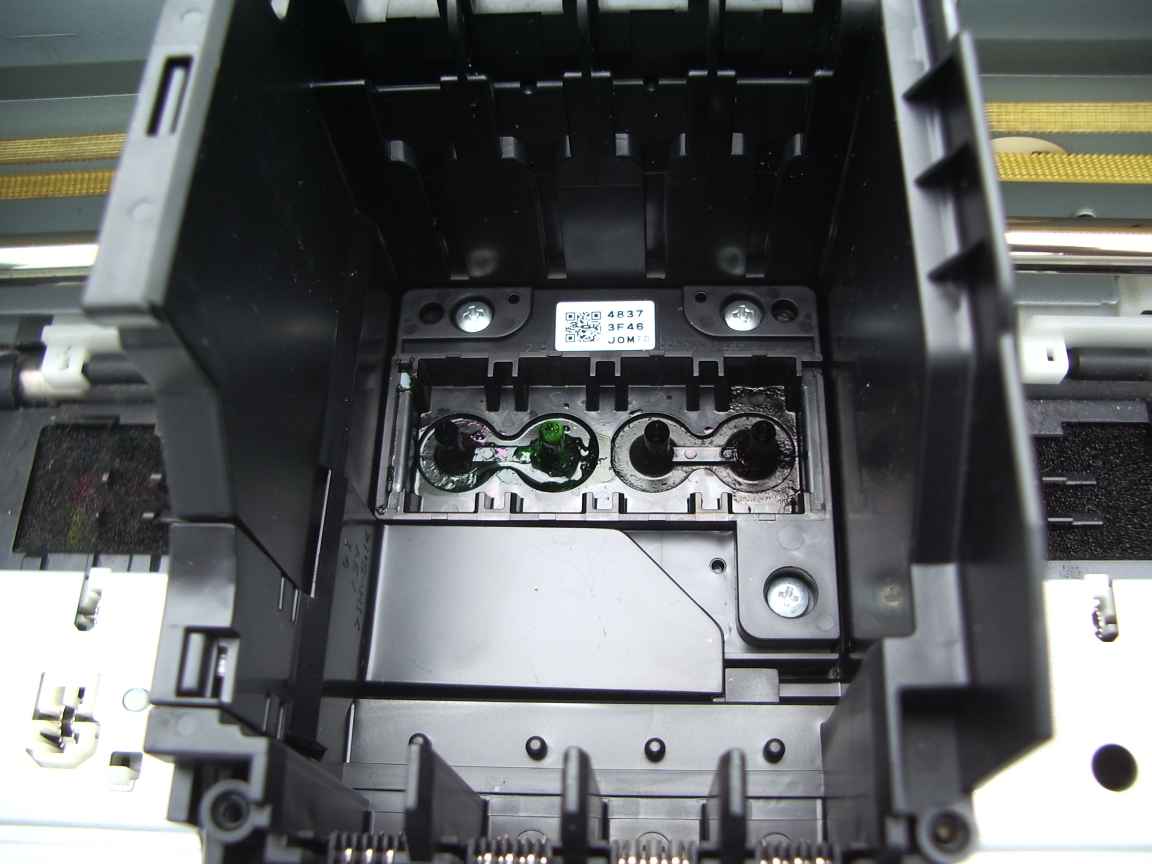

| The ribbon cable can be removed from the nozzle plate by pulling gently. Maintain the orientation of the ribbon folds. It must go back exactly the way it came out. | This is the "business end" of the nozzle plate. Notice the amount of dried glugged up ink. Zoom in and you can just see the nozzle holes | clean the wiper, rubber caps, and while working, keep these mechanisms moist with a damp cloth

|

|  |  |

| | The

scanner hinge has 3 cables carefully threaded through it. Free

the cables from the main body by first removing a little cover plate

immediately below this hinge. |

Here is an idea !

Save

your empty ink tanks and refill a set with liquid detergent. Then just

run the normal unclogging procedure. You will need to find the printer

resetting programs, again at your risk from mystery Russian site.

Must think about that one!

homepage

page created Thu Nov 25 17:54:19 EST 2010