The

etching of copper clad printed circuit board.

2007

for the practical radio amatuer in Australia

The

radio amatuer in Australia is now left with some stark choices when it

comes to the home production of copper printed circuit boards.

There are superb personal computer based PCB design softwares

that will print artwork onto overhead transparency film on a laser

printer. Thats all well and good but have you tried to get

photo

sensitive resist materials in Australia lately ? It is just

about

impossible. RCS Radio in Sydney can sell you some pre

sensitized

material but it is very costly and has limited shelf life.

The marvelous Riston coated board material is no longer

being

produced. This was a magic material, moderate exposure under a disco

black light tube would result in high contrast rock hard traces.

There were many other photoresists available in the eighties

including some excellent positive resists that came in a spray can.

I wrote to the marketing manager of Electrolube which make a

superb positive photo resist but the reply was to the effect that it

was not worth their time and money to market the product in Oz.

Thats a very sad reflection on the state of manufacturing in

this

land. Jaycar sell small quantities of a presensitised board but it is

extremely costly.

The

Dalo etching pens are hard to use and I dont think I have ever been

really pleased with the result. The resist is hard and very resistant

to abuse but the pen has very uneven flow and dries and clags up very

rapidly. It is useless for "coloring in" larger not to be etched areas.

It is very good , however, for repairing resist areas that are too thin

or badly exposed. I used a bog standard Texta or other spirit

based marker pen for resist. The resist film is very thin but will last

long enough to etch good quality lands , pads and lines. A long time

ago I used bituminous paint to paint on the tracks. This was hard,

messy, error prone and a complete pain. It is still a very effective

resist and was in fact the very first photographic medium. Lately

I have been using a spirit based pen known here as "permanent

overhead transperancy marker". These pens come in assorted sizes. The

Black pen writes very well onto clean copper, the larger pens

write a nice thick steady line and can be used for filling large areas.

The ink dries and hardens quickly and is a superb resist. I will

never use Dalo pens again.

This little board was recently made with the overhead transpenracy pen as the only resist.

I am

experimenting with something called collotype, which is a

photosensitive material made with food grade gelatine which has been

activated with ammonium dichromate to render it photosensitive.

It is hard to use because gelatin is not one substance but a

mixture of variable molecular weight proteins that are cross linked

under the action of ultra violet light. It is , in fact, one

of

the oldest photosensitive resist materials and the collotype printing

process is almost as old as modern typography. Ammonuim

dichromate will also photosensitise poly vinyl alcohol glue,

but

I have not done any experiments along that line yet. PVA is a

more consistent material than gelatine and promises better results.

The

method that I have been using mostly ,off late, for rapid prototyping

is the Dremel method. Using a tungsten carbide cutter, quick and

efficient removal of copper is achieved. As you are literally carving

lands pads and tracks with the Dremel, this limits the scope of whats

achieaveable. It is totally unsuited for digital work, but

most

of the type of analog circuits constructed by hams are ameanable to the

Dremel. It is another variation on the dead bug style or the

more

pernikity "Manhattan Method" which uses precut PCB offcuts to create

lands. Dont use a steel cutter, the glass in PCB material will

instantly dull them. Insist on tungsten carbide!

There

still remains the problem of etching PCBs. The many

electronic

enthusiast suppliers in Australia are still happy to supply either

ferric chloride or ammonium persulphate etchants as either

concentrates or ready made solutions. Ammonium persulphate

should

only be purchased as the powder, the solutions have no shelf live at

all. Ferric Chloride still remains my favourite etchant despite its

tendancy to leave persistant stains and corrode anything metallic

within a ten light year radius. ( I am a firm believer in the telekinetic

powers of ferric chloride. I am sure it has the power to rust steel

tools a light year away! Probably can go back in time too!) Never do

etching with ferric chloride indoors, with the evolved acidic mist your tools will rust into history!

Ammonium

Persulphate is probably the "greener" etchant as this will harmlessly

degrade to bog standard common fertilizer. Ferric Chloride is

persistant (and nasty) and thats why I like it.

Ferric

Chloride etchant can be re used almost indefineately, indeed, I still

use a solution thats over ten years old! (How green is that!)

The

chemical reaction between copper metal and ferric chloride is a complex

one and is still not completely understood by the chemical community.

In it copper metal passes directly into solution without the evolution

of hydrogen gas as would be engendered by dissolution in acid.

You do not want to generate gas in any case because the gas

will

lift away the resist and ruin edge contrast. The copper metal is

ultimately oxidized to cupric chloride in solution after being first

oxidized to the partly soluble cuprous chloride. The

oxidising

potential of the ferric chloride is quickly consumed by the

copper metal and very soon the initially vigorous reactions slows down.

The etching action can be accelerated by agitation and heat,

and

this is the standard method.

Ferric

Chloride can be regenerated. The initial reaction with copper

metal reduces the ferric to the ferrous ion which is very reactive in

the pressence of atmospheric oxygen. This results in the

precipitation of a hydrated ferric oxide and hydroxide which is highly

insoluble and is the major component of the brown gunge that grows near

and in your etching container. It also grows over the fresh copper

surface inhibiting rapid etching.

Agitation by bubbling air

through the etching tank is now an established method for accelerating

the etching process. This has also the beneficial effect of

reoxidising the ferrous ions back to ferric. There is

however, a

stochiometric deficiency of chloride and hydrogen ions. This can be made

good

be acidifying the etchant with biulders grade hydrochloric acid.

The resulting etchant takes on

an evil looking deep green but has no turbidiy due to suspended ferric

oxide. In this form the same etchant can be reused almost

forever, that is until the high concentration of cupric chloride

inhibits further action, due I guess, to the common ion effect.

I

have not experienced that in any of my etching baths yet. There is a legitimate arguement that more cupric chloride is good too.

With

acidification with HCL and bath agitation with bubbled air,

satisfactory etching action can be achieved without any heating and the

etching solution does not need to be discarded but has a "near

infinite" life.

Unwanted spent etchant should be mixed

with calcium hydroxide/carbonate ( garden lime) before

disposal

and this will render this etchant safe as immobile iron and

copper hydroxide/carbonates and will also nicely neutralize the

remaining acid. Never pour unwanted etchant into a toilet bowl or

stainless steel sink , it will result in an intractable stain. (and

domestic woes )

The

spent ferric chloride solution may also be rejuvenated by adding

a wad of steel wool. This has a the effect of displacing copper metal

from solution, it is reducing cupric copper (+2) to cuprous

copper (+1) and copper metal. Quickly filter out the precipitated

copper metal and add hydrochloric acid and aerate. This will regenerate

the the ferric chloride.

In

other new, I recently came across a website that exhibited

the novel, yet totally feaseable method of using Cupric Chloride as the

etchant. When I refind the link, I shall repost it here. In

summary, Cupric Chloride reacts with metallic copper forming

cuprous chloride. This reacts with disolved oxygen in the etchant

solution and is oxidised to the more soluble Cupric Chloride. The

stochiometric deficiency of chloride ions is made up by either direct

reaction with chlorine gas or more practically , hydrochloric

acid. This etchant solution, potentially lasts forever and gets better with use , still no free lunch, air and HCL are still required.

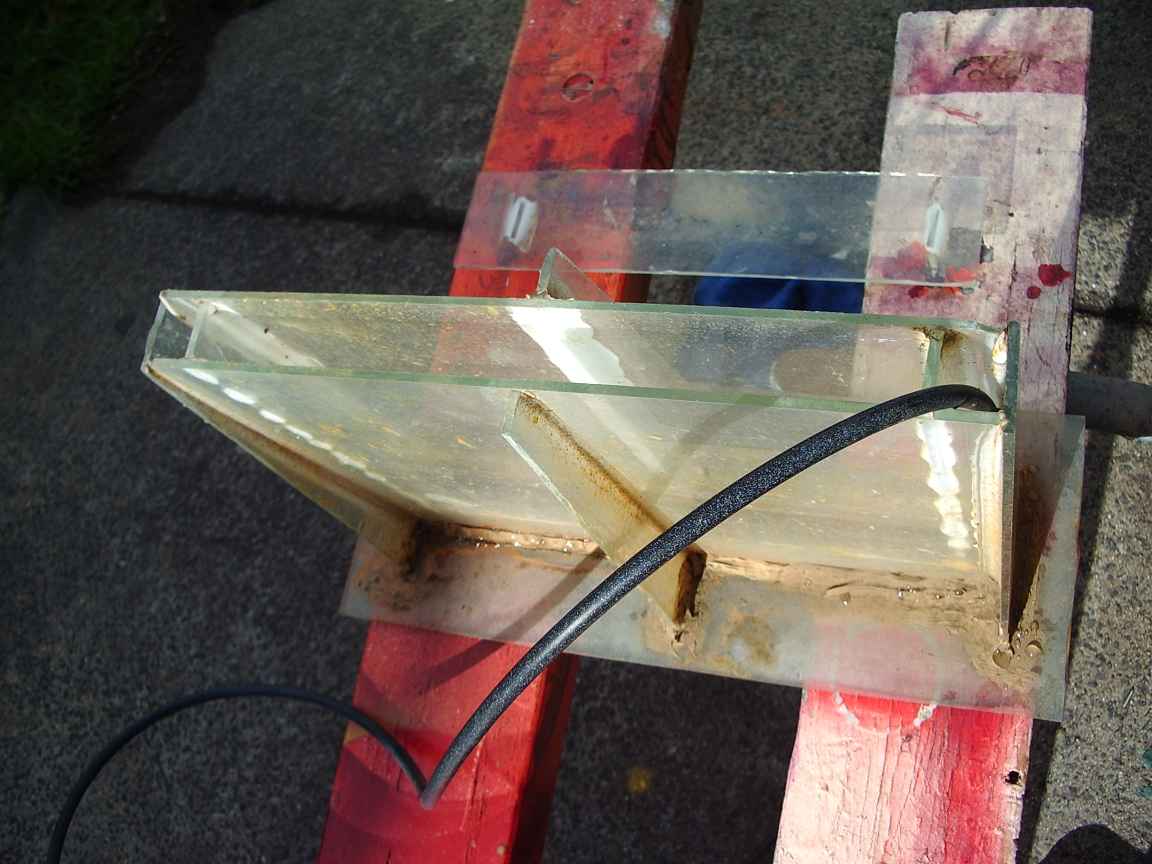

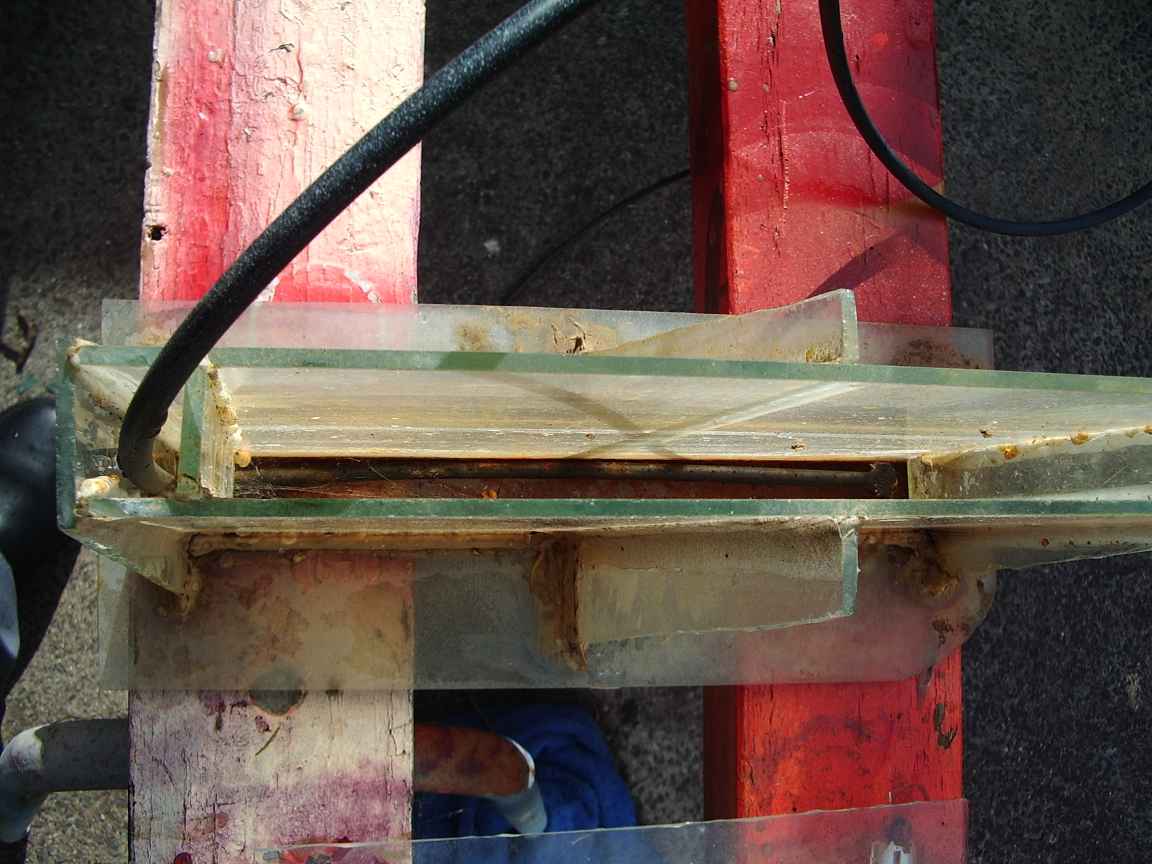

The

following images are my etching tank, constructed from glass sheets and

silicon sealant. If you choose to make a tank from glass like

this do use the so called acid cure external guttering grade

silicone rubber. I made the mistake , in this model , of

using a

white rubber, which is filled with pigment, probably alumina. The

pigment reacts with the acid. The air plumbing is standard

garden

drip feed tubing. The air nozzles are made by crimping the end of the

tube shut by heating the tube and crimping with a heated pliers. Small

holes are drilled in the pipe.

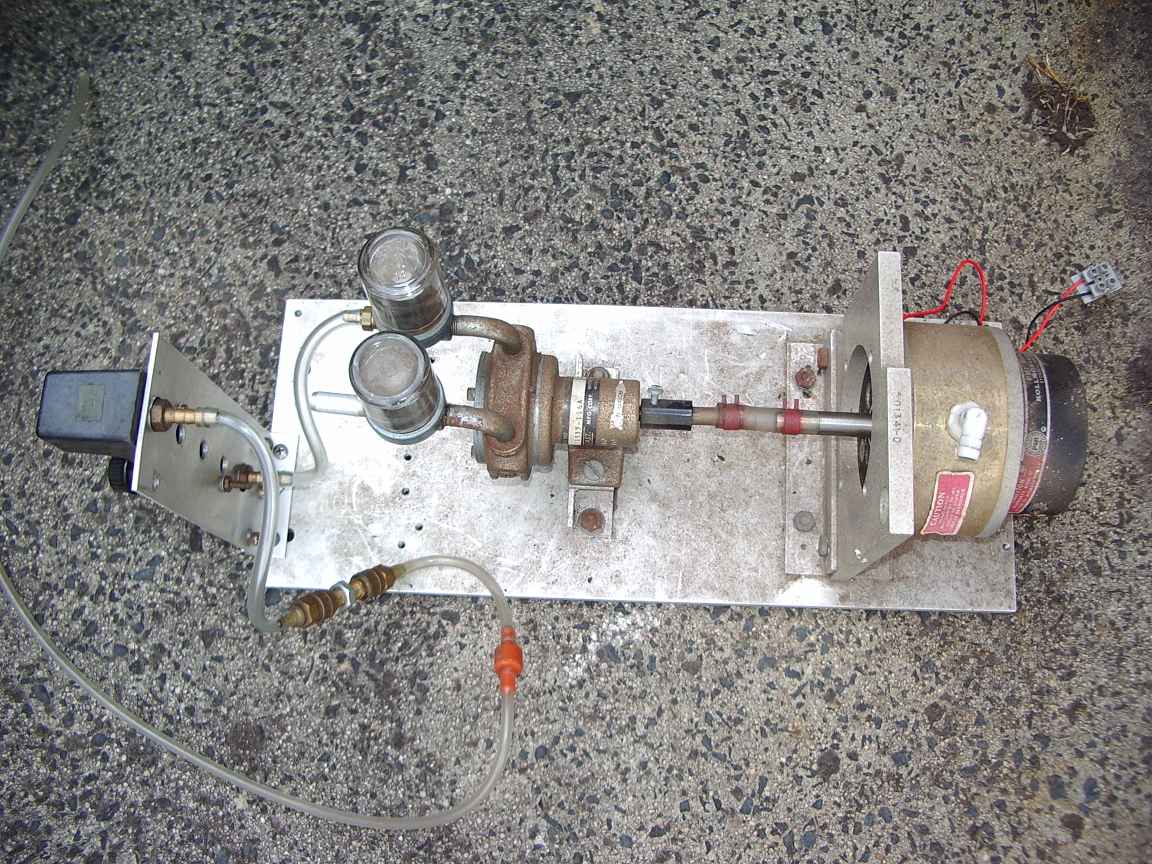

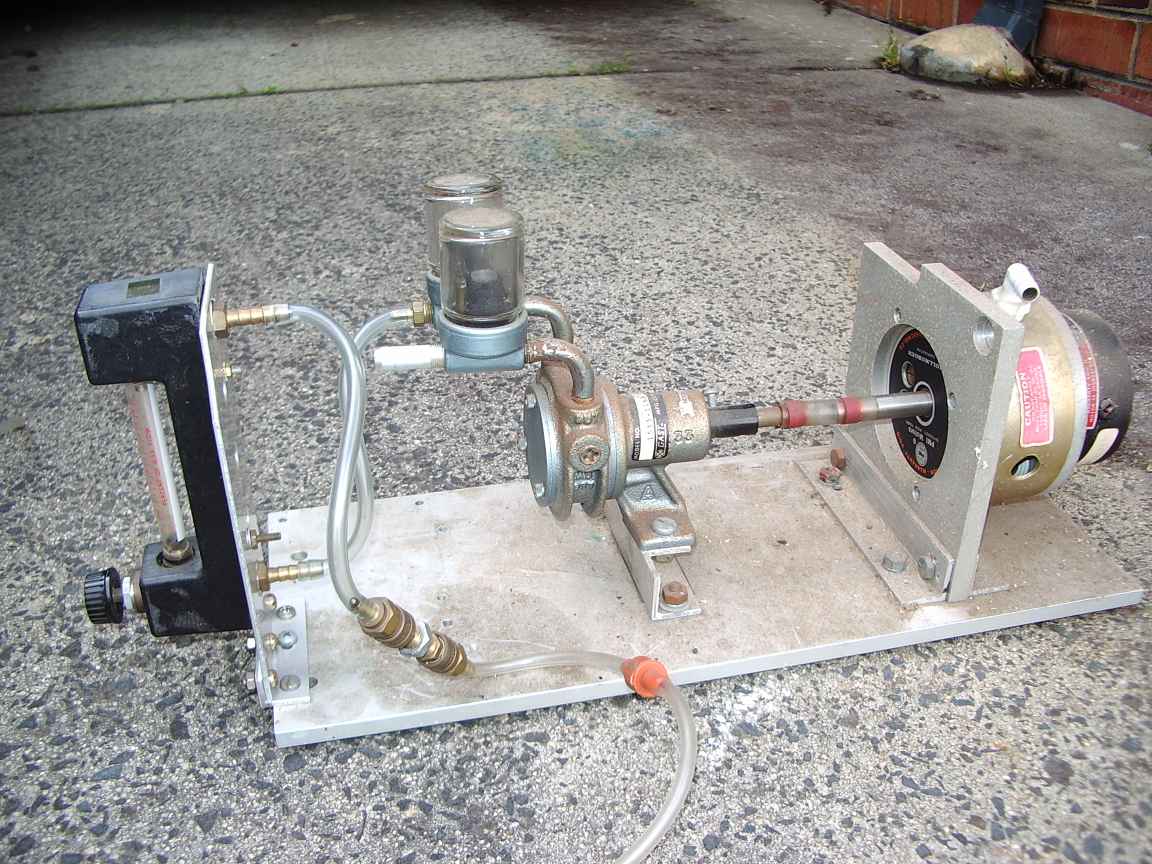

The

pump, motor and air flow indicator (rotameter) were all found in skips

at work. Aquarium pumps with some means of

regulating air

flow would be also satisfactory, cheap and readily available. You cant

have too much air flow. If the air causes etchant to be expelled

then you have too much! The air plumbing also includes a one

way

non return valve. This is to prevent any possibility of backflow by

siphon action of etchant back into the pump. It also prevents corrosive

vapours from finding their way into the pump. To be

absolutely

sure of preventing siphon action backflowing into the pump, allways

mount the pump higher than the etchant tank.

A note on the storage of this etching solution.

Aerated

, acidified ferric chloride solution is actually quite a powerfull

oxidising agent. It must be, after all, it can oxidise metallic copper.

It can even oxidise polyethylene. I discovered this the hard way when I

had drained my etching tank of fluid to safely store it away, as I do

not want animals or children to access the tank contents. After a

couple of years of neglect, the polythene bottle had completely

corroded at the liquid-air interface. The plastic had

become extremely brittle and a slow leak was evident. PET

bottles seem to be more resistant to this oxidation, but now I

change the bottle every year. Glass bottles are best, off course,

but it is hard to find one with a lid that will not disintegrate or

irreversibly bind.

For those that must know, the motor is a 50 volt dc servo motor and the

vane pump come from a long dead Burroughs 9 track tape drive. There is

a one way check valve to prevent backflow and reverse siphoning. The

check valve can be sourced from auto wreckers and (my guess) aquarium

suppliers.

homepage

email sig, links Fri Feb 26 13:31:17 EST 2010;Fri Oct 1 18:38:22 EST 2010