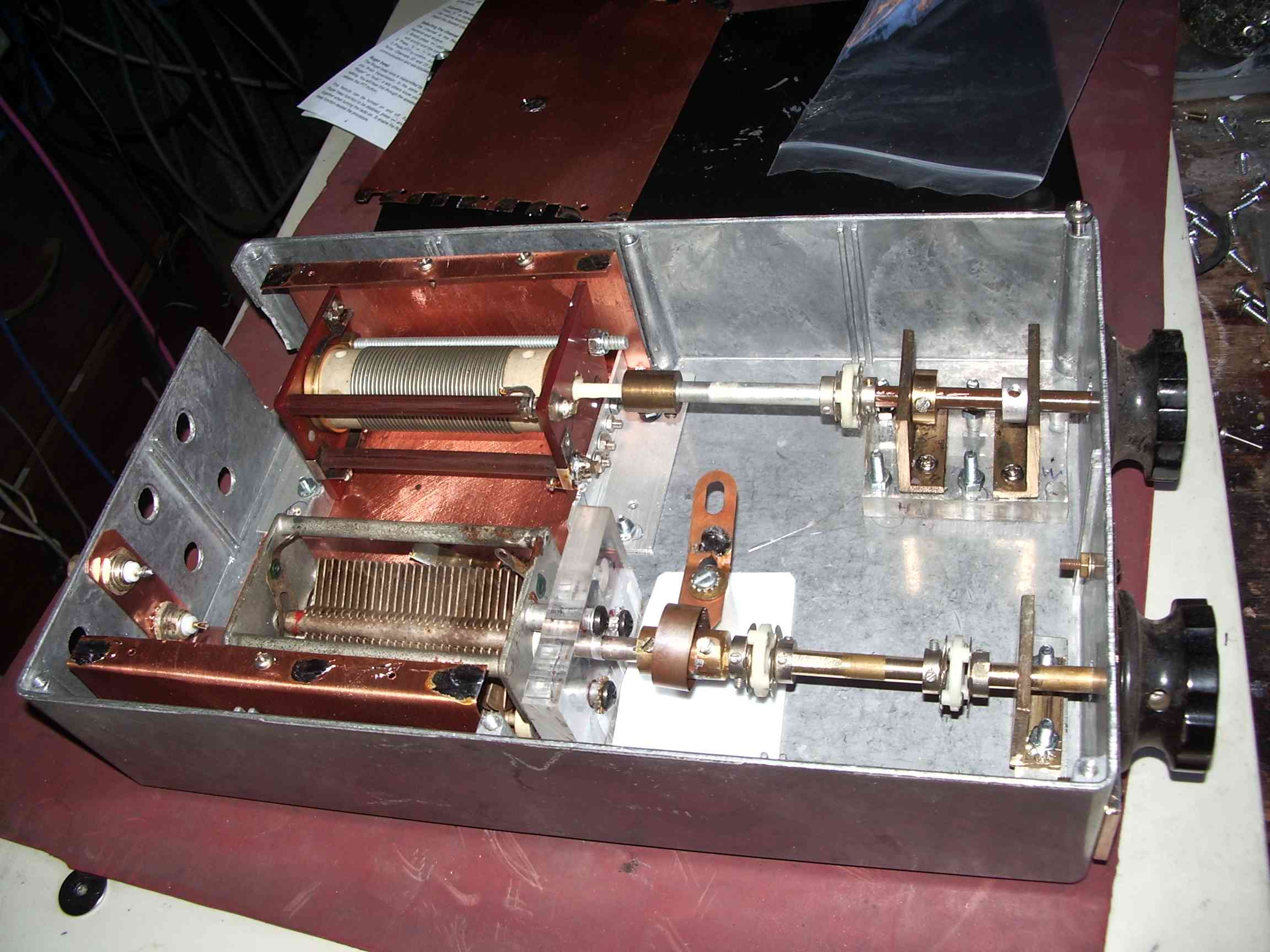

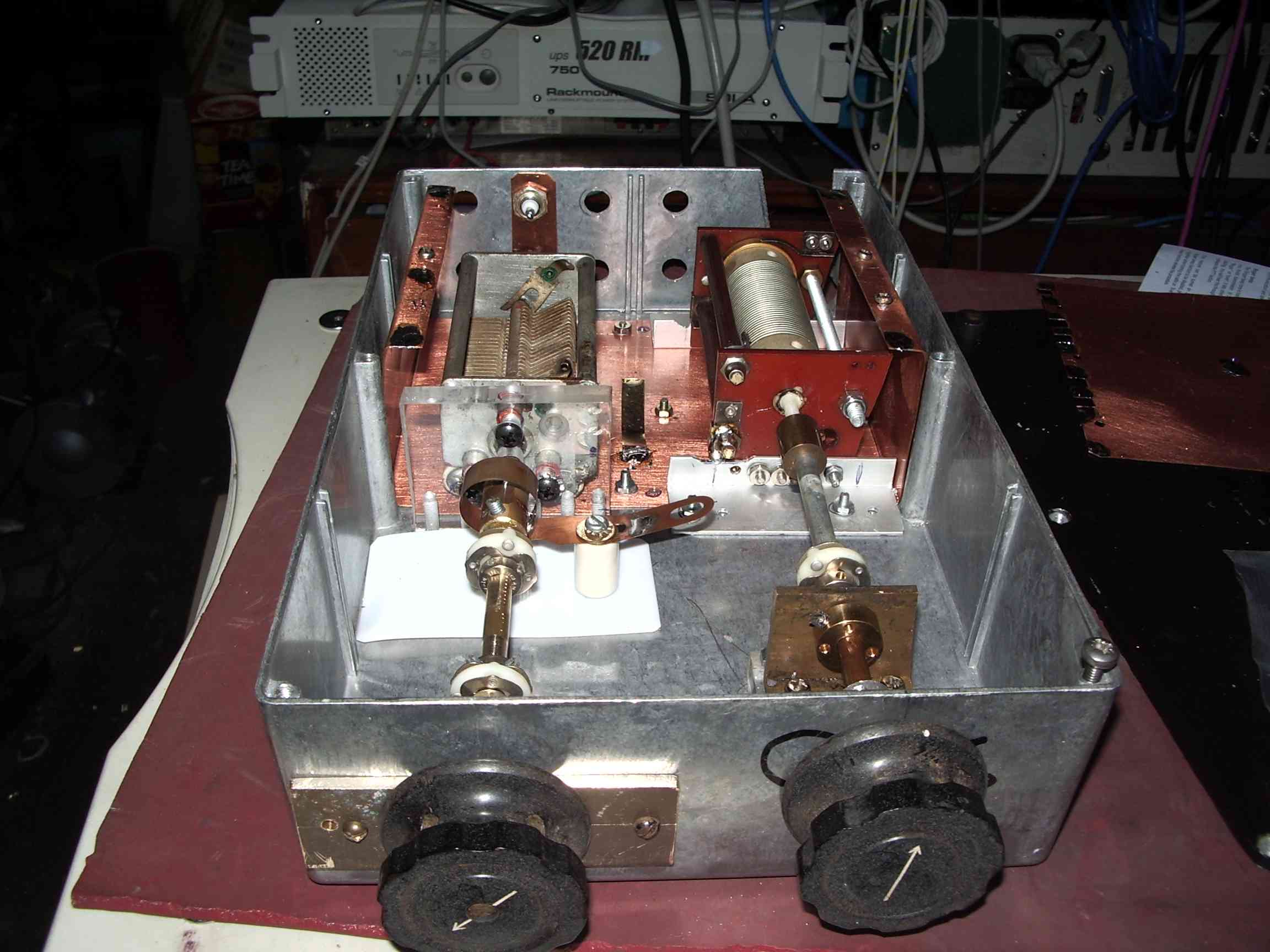

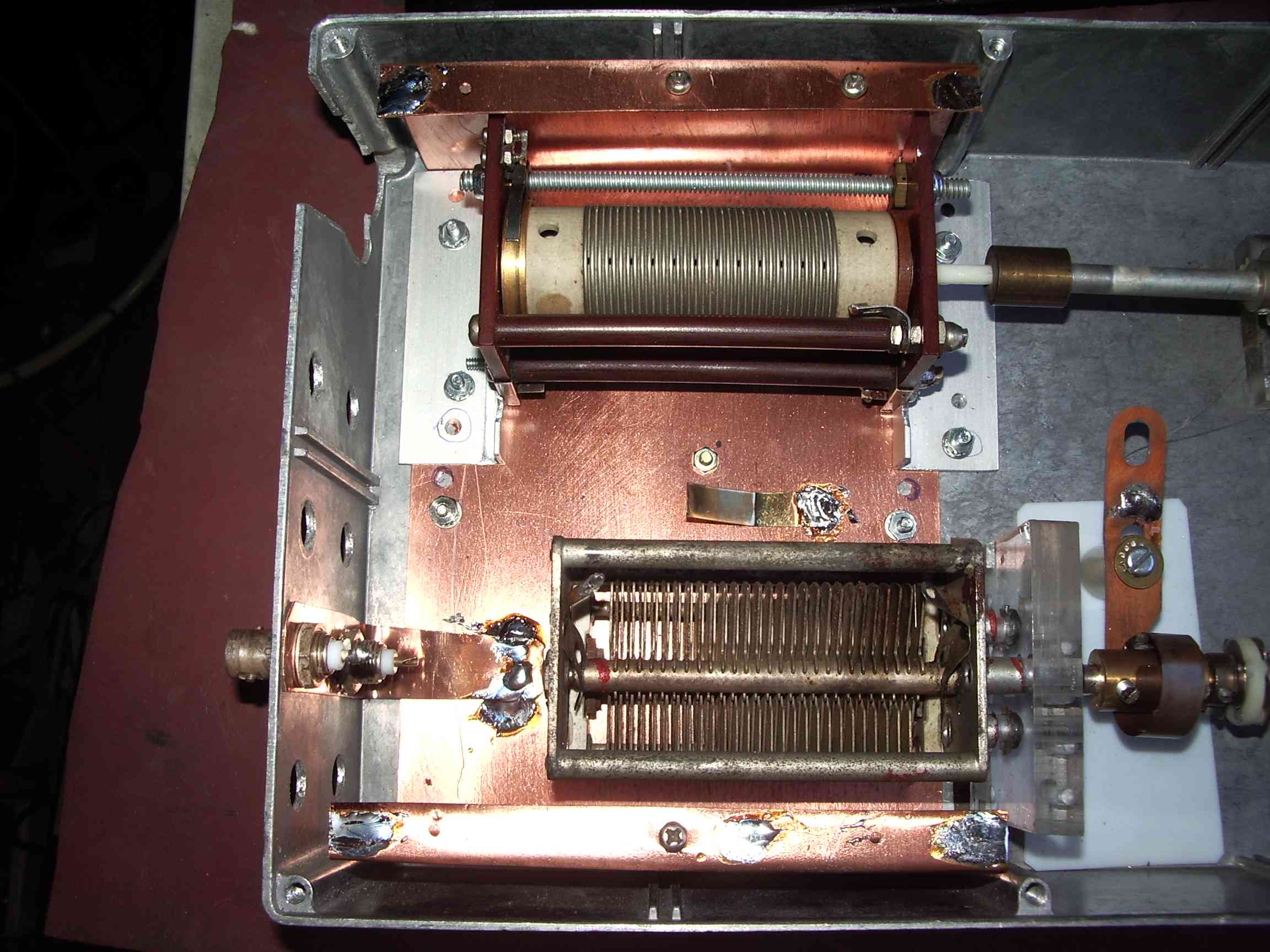

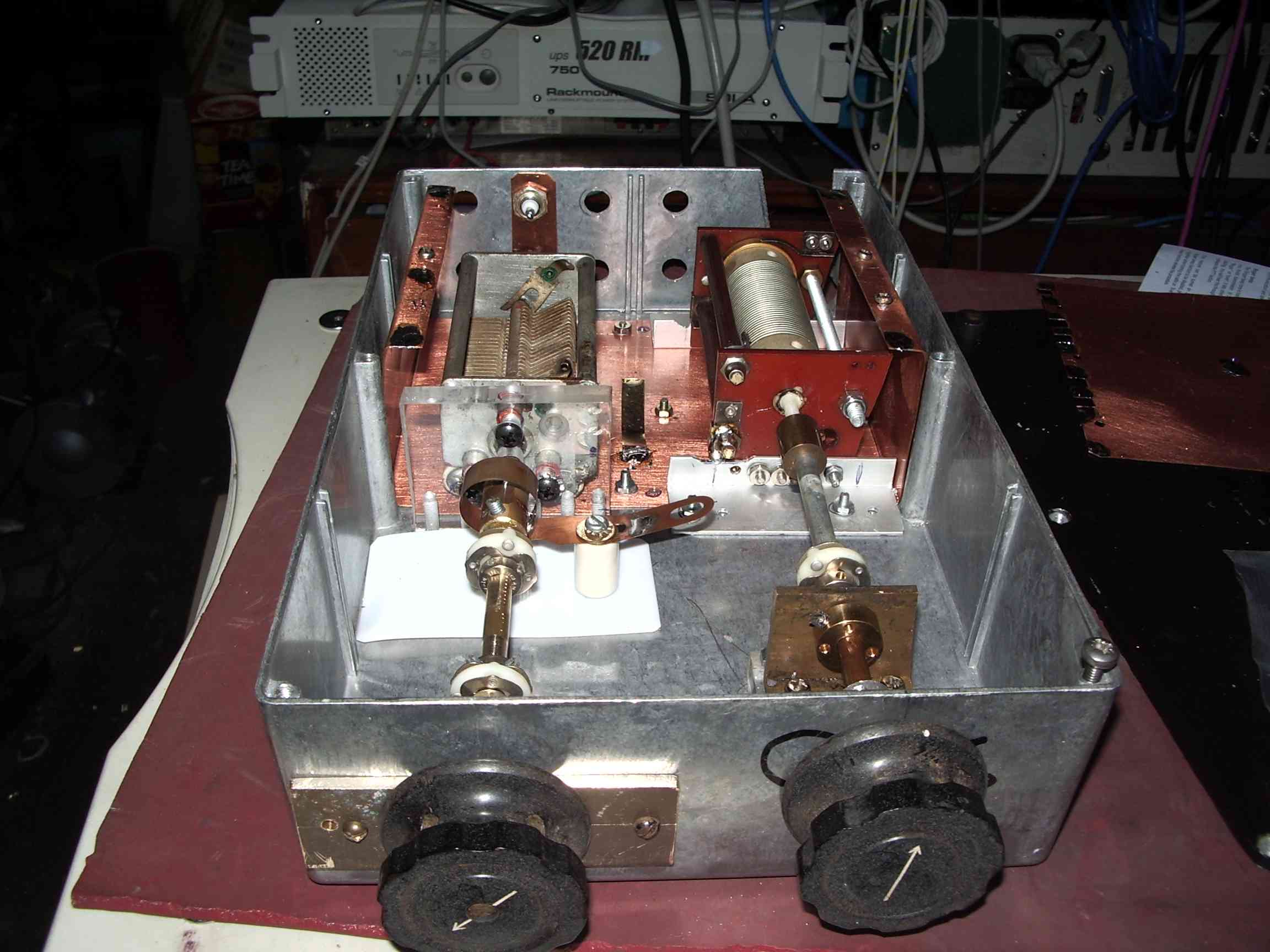

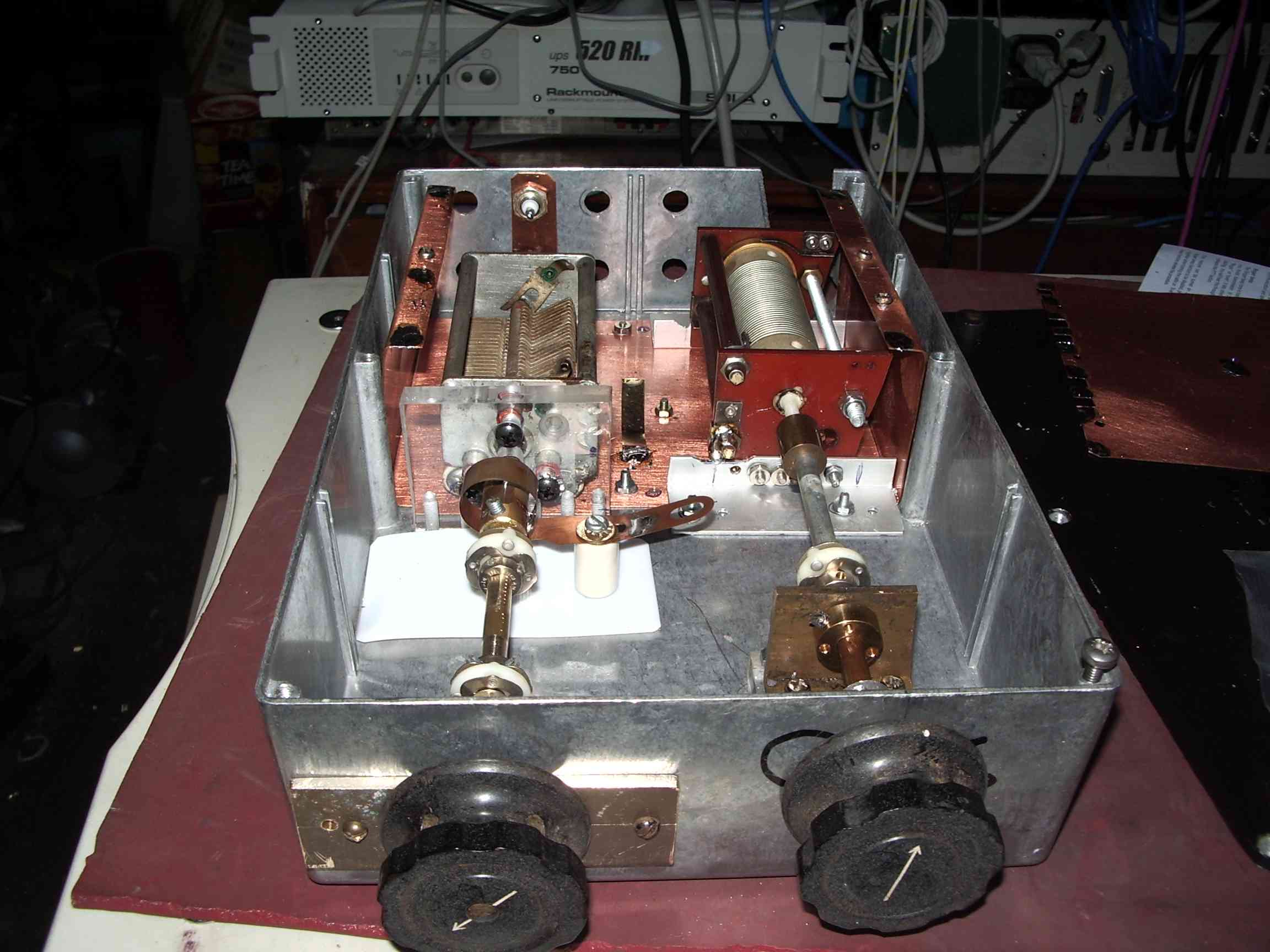

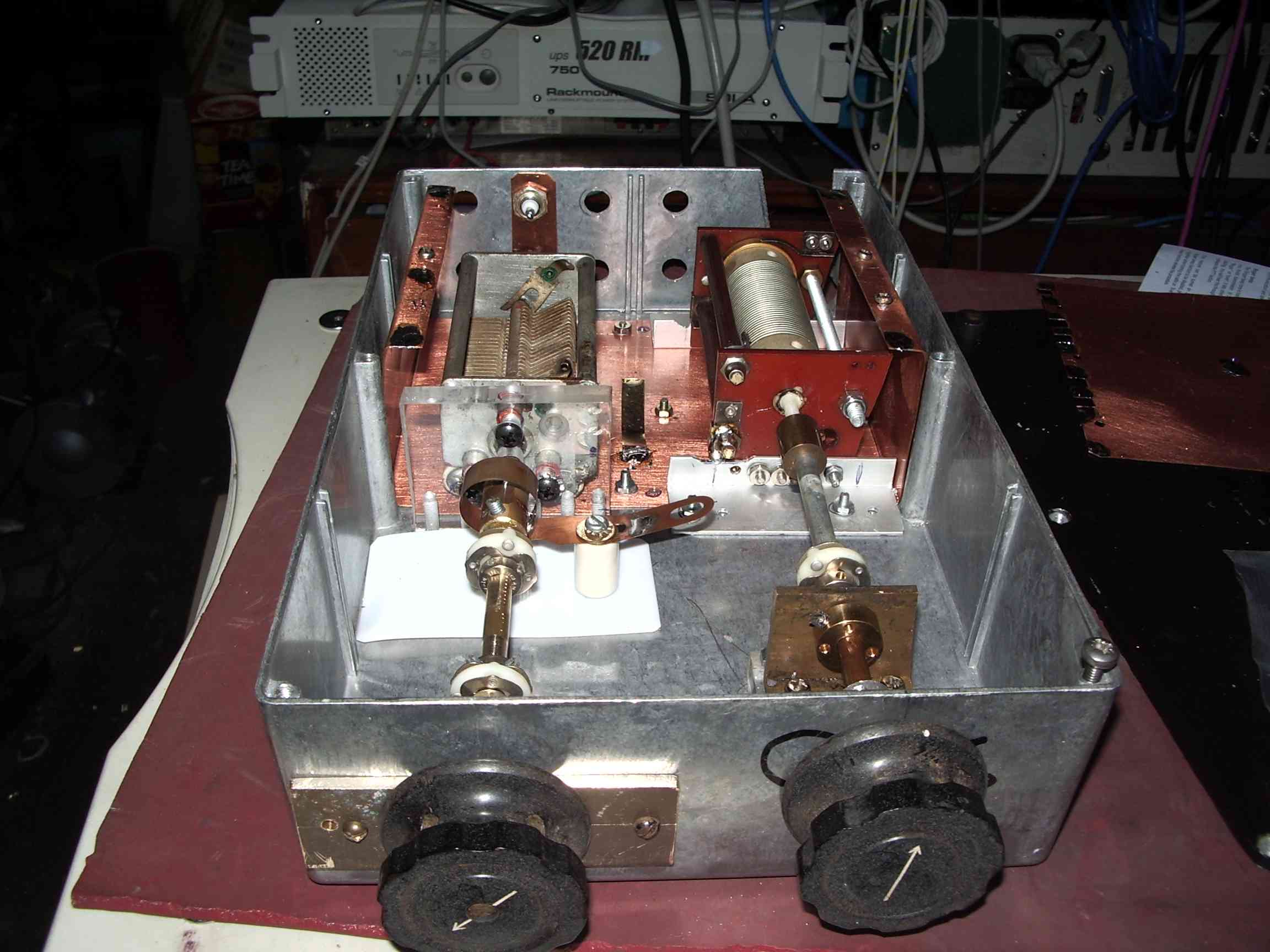

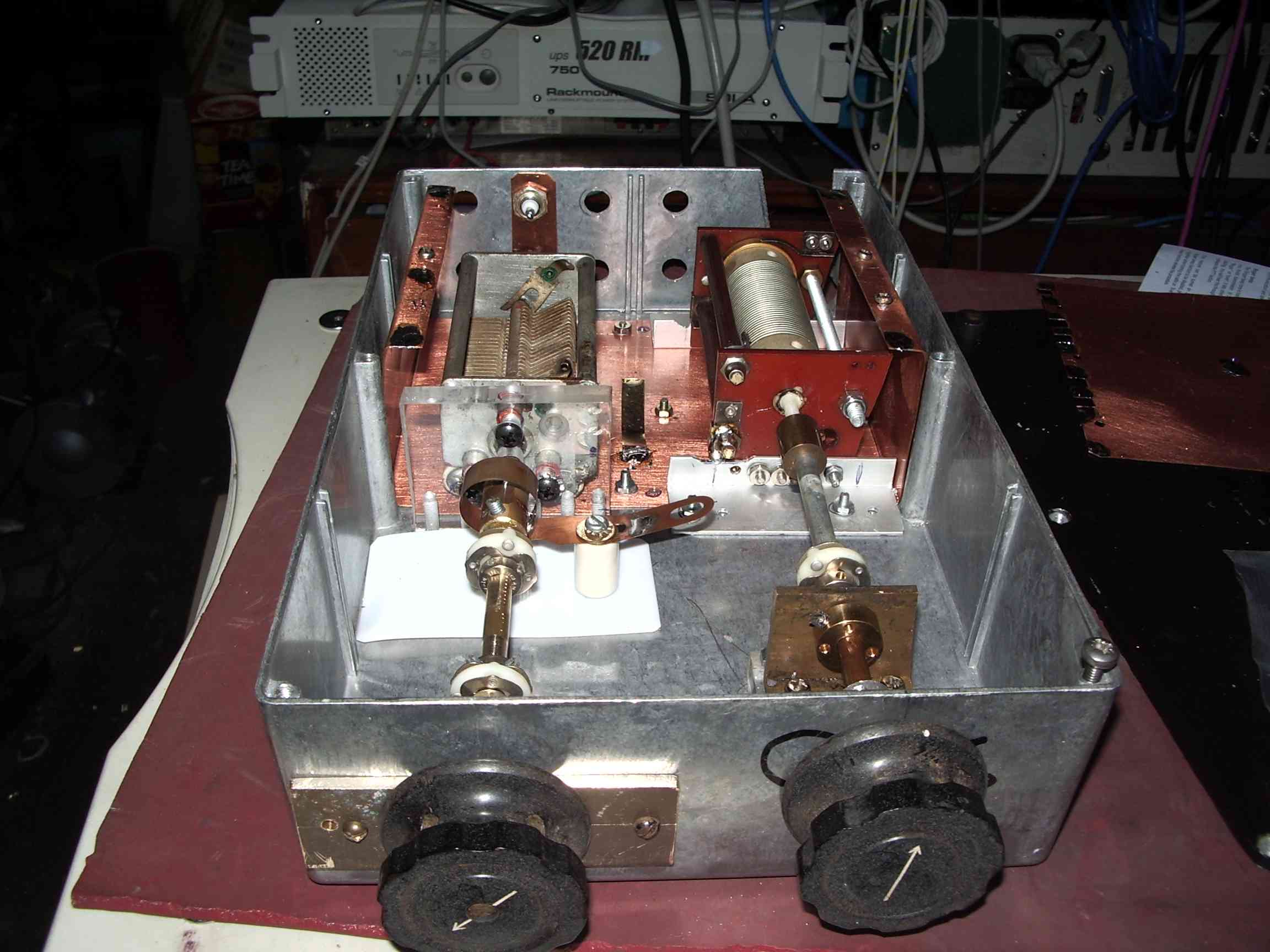

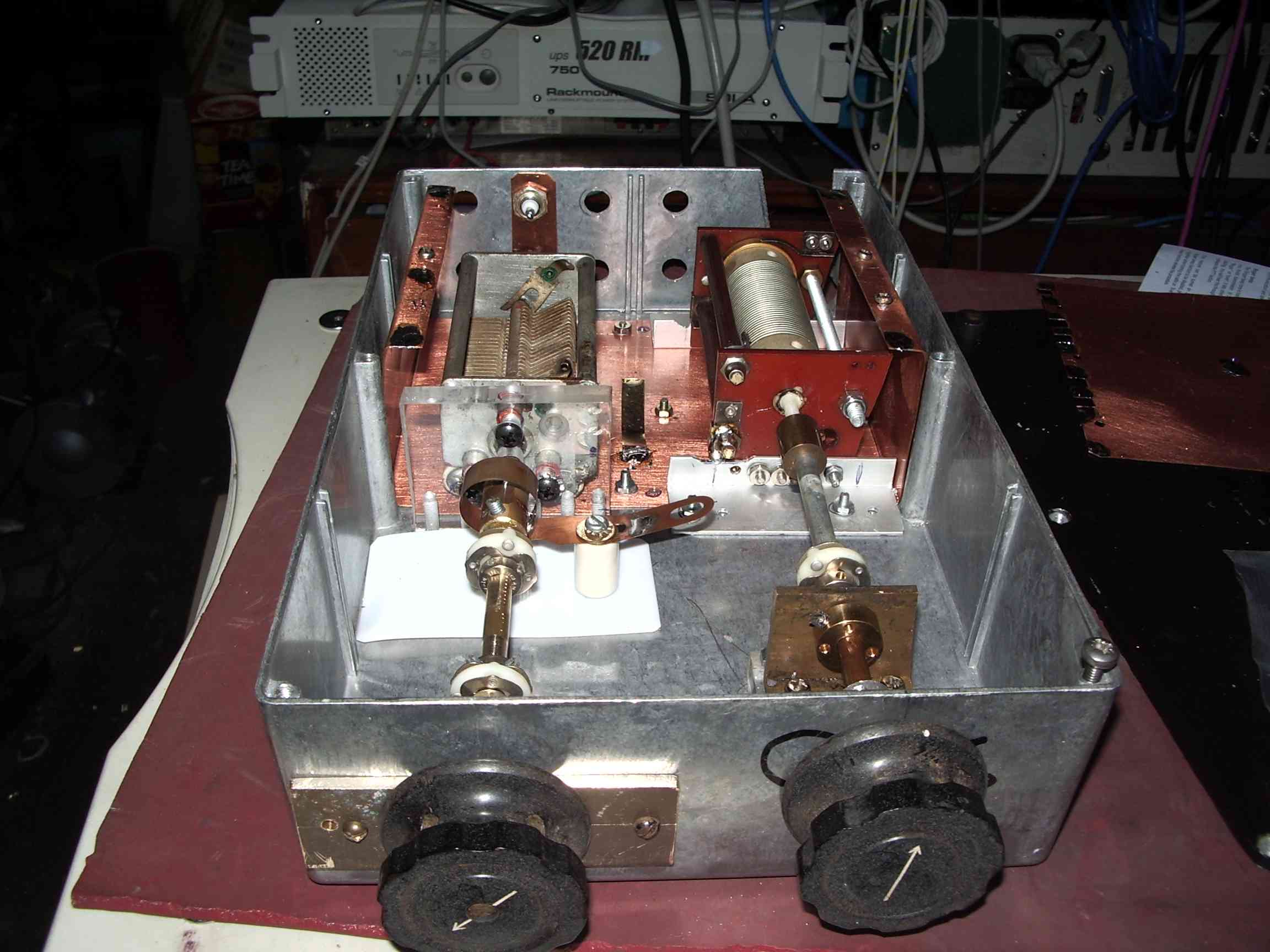

L match antenna tuning unit for 80 40 and 20 meters

as biult with found items

Ralph Klimek Sept 2007

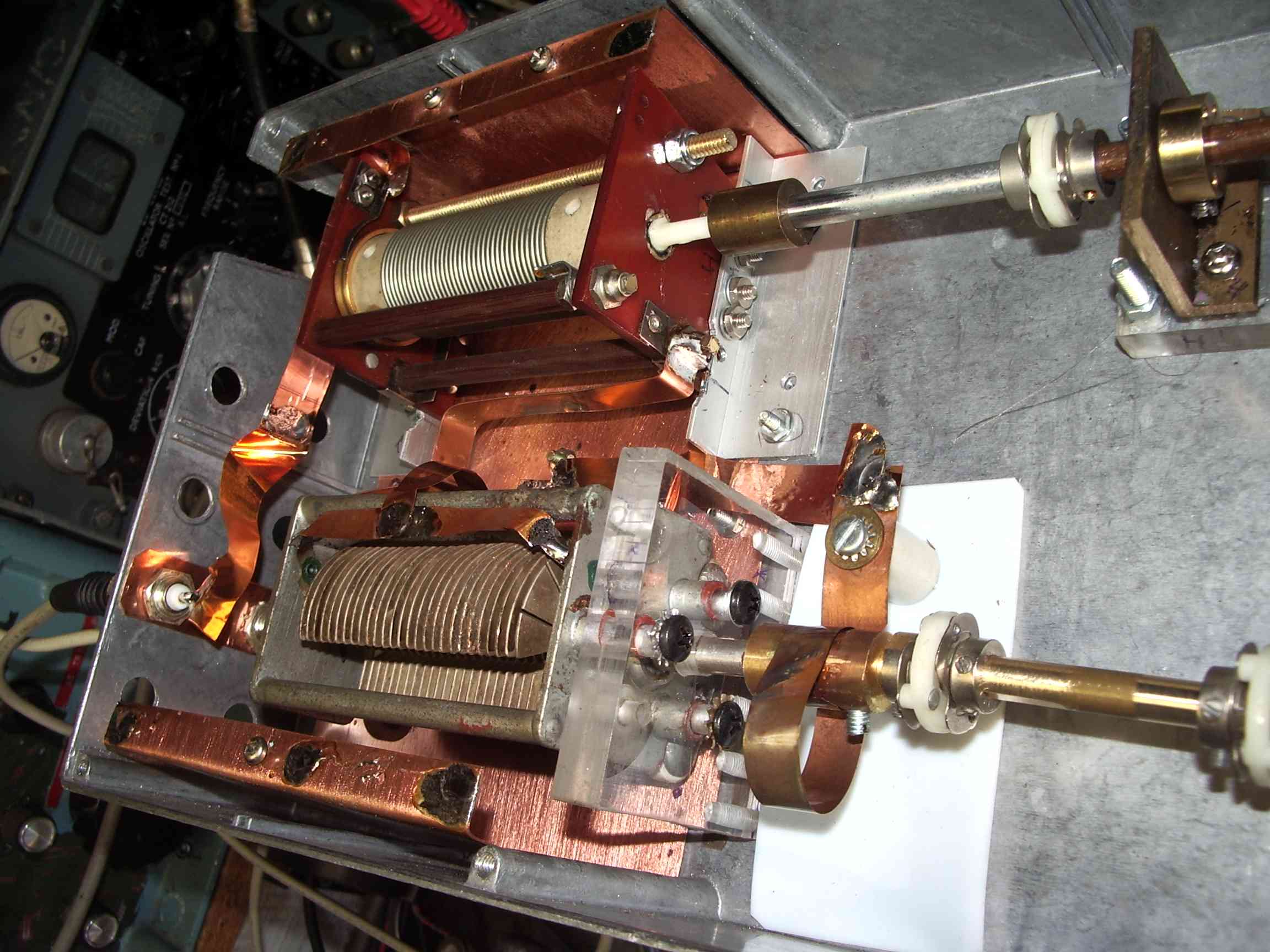

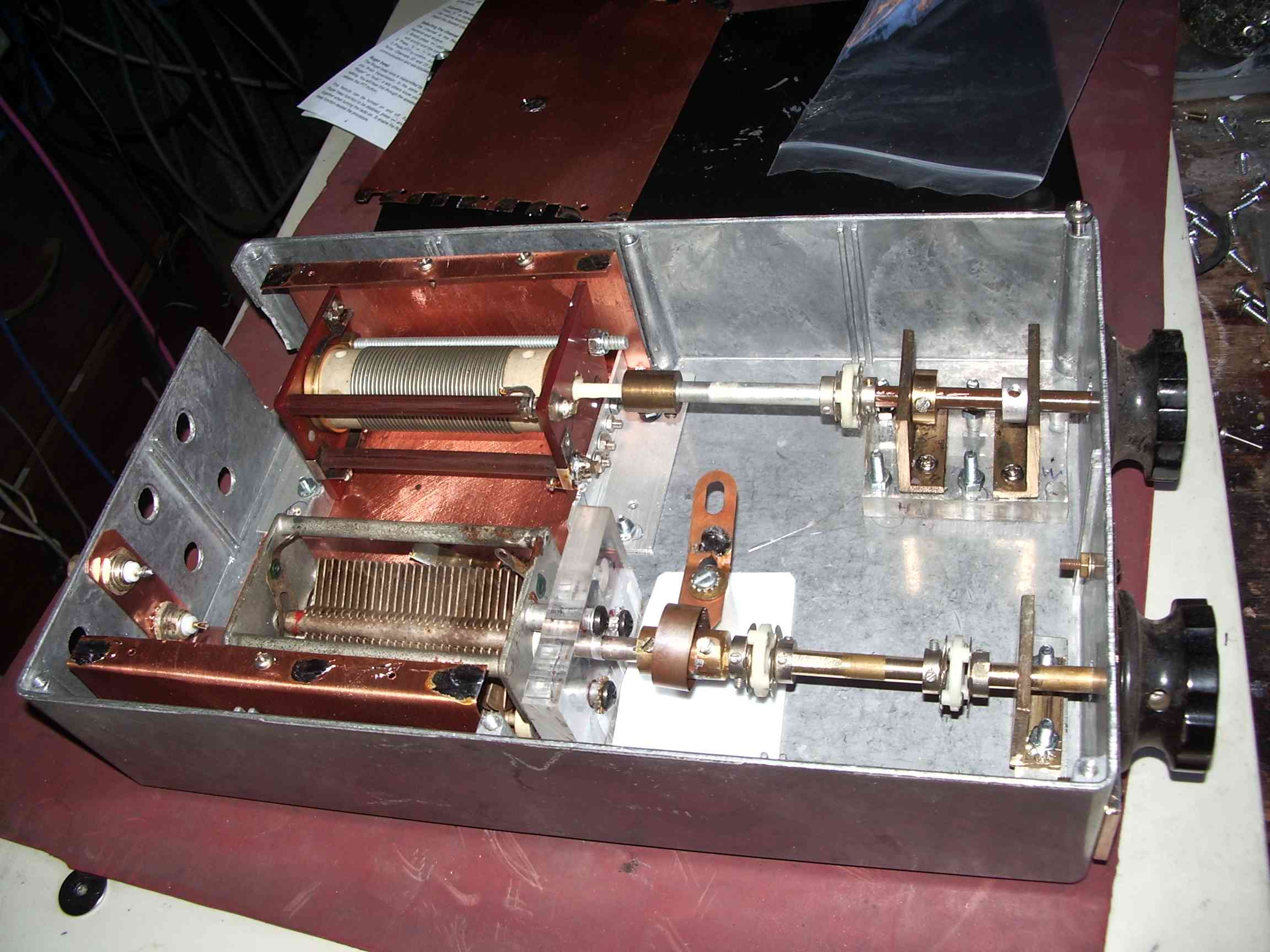

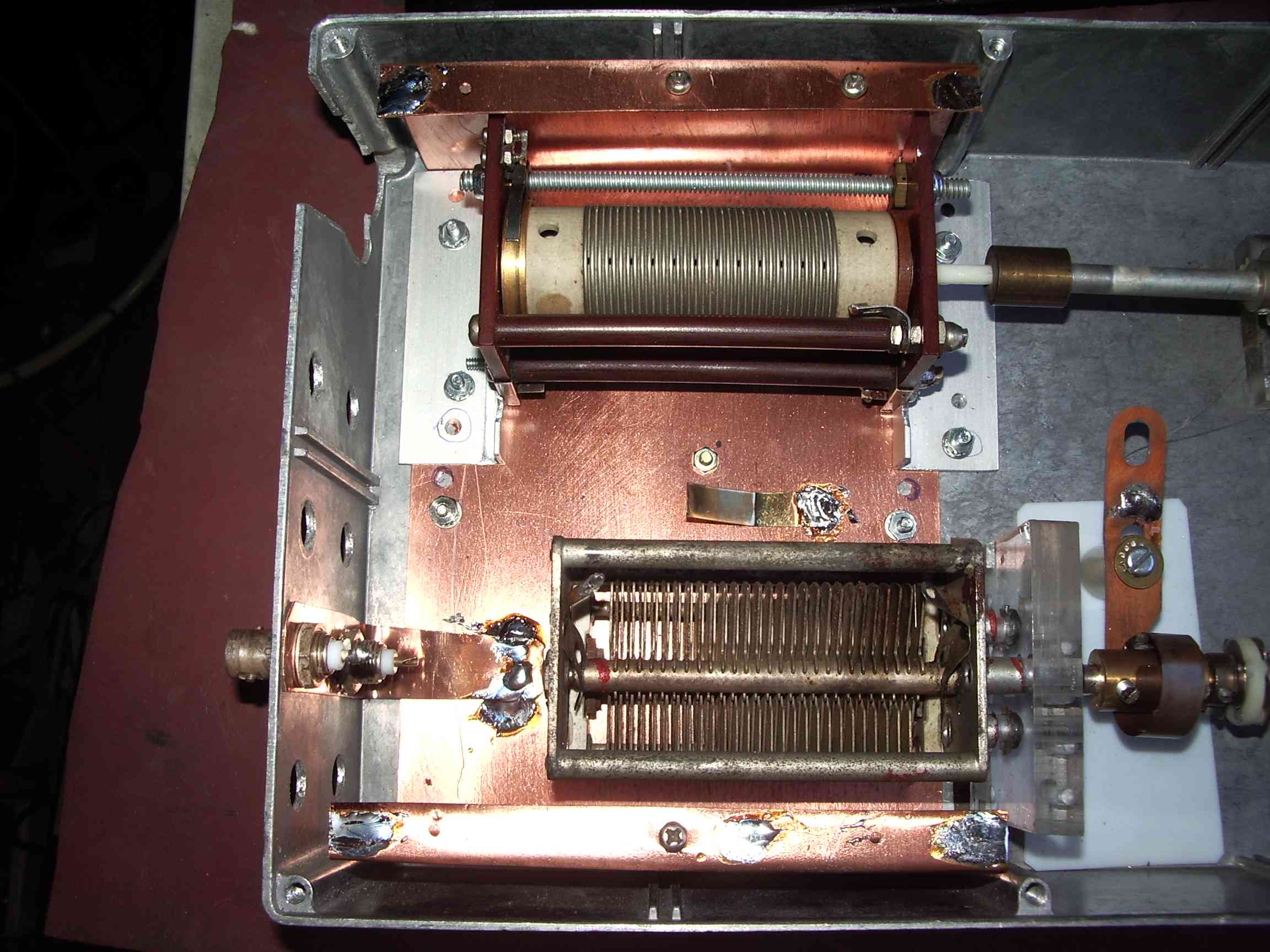

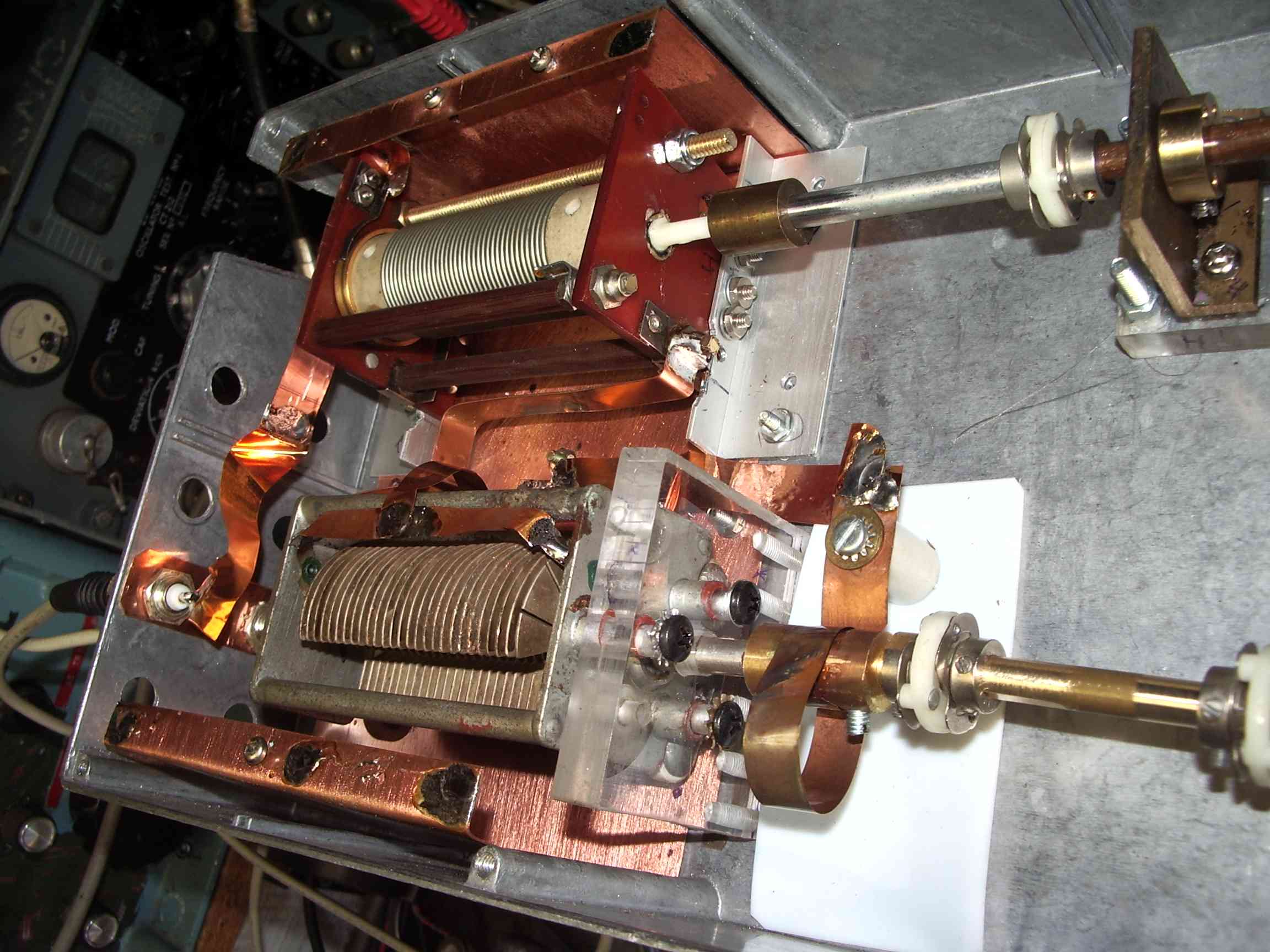

The roller inductor was purchased at a hamfest about 10 tens ago and

was mouldering away at the bottom of my junk box. It was originally a

double roller that came from some fixed frequency Collins transmitter

of some sort sort. I cut the double assembly apart and

added some extra hardware to make it a standalone unit. There was no

provision for an external drive shaft so I drilled it and glued a fibre

glass rod to serve as a drive shaft. It was originally designed for

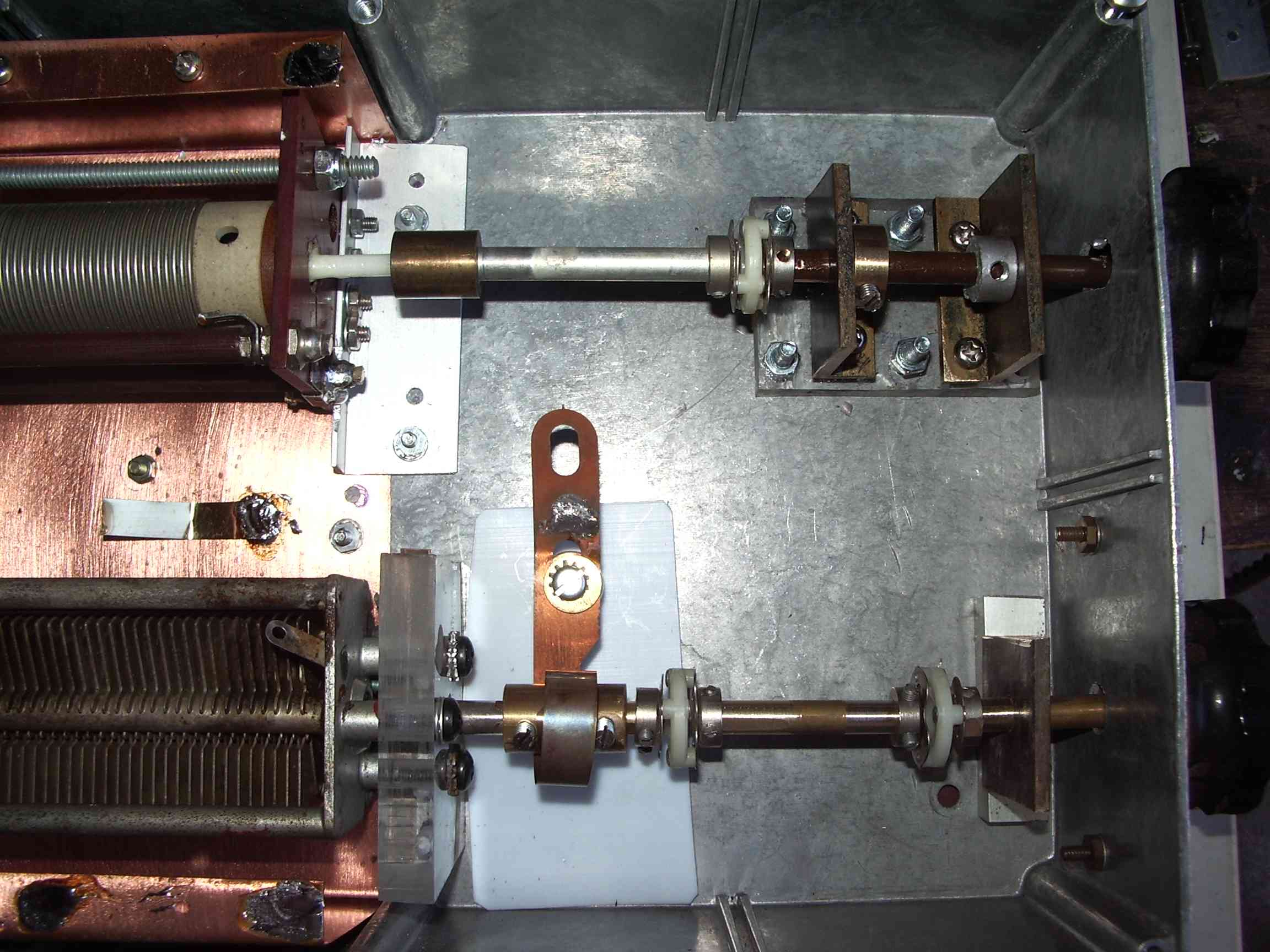

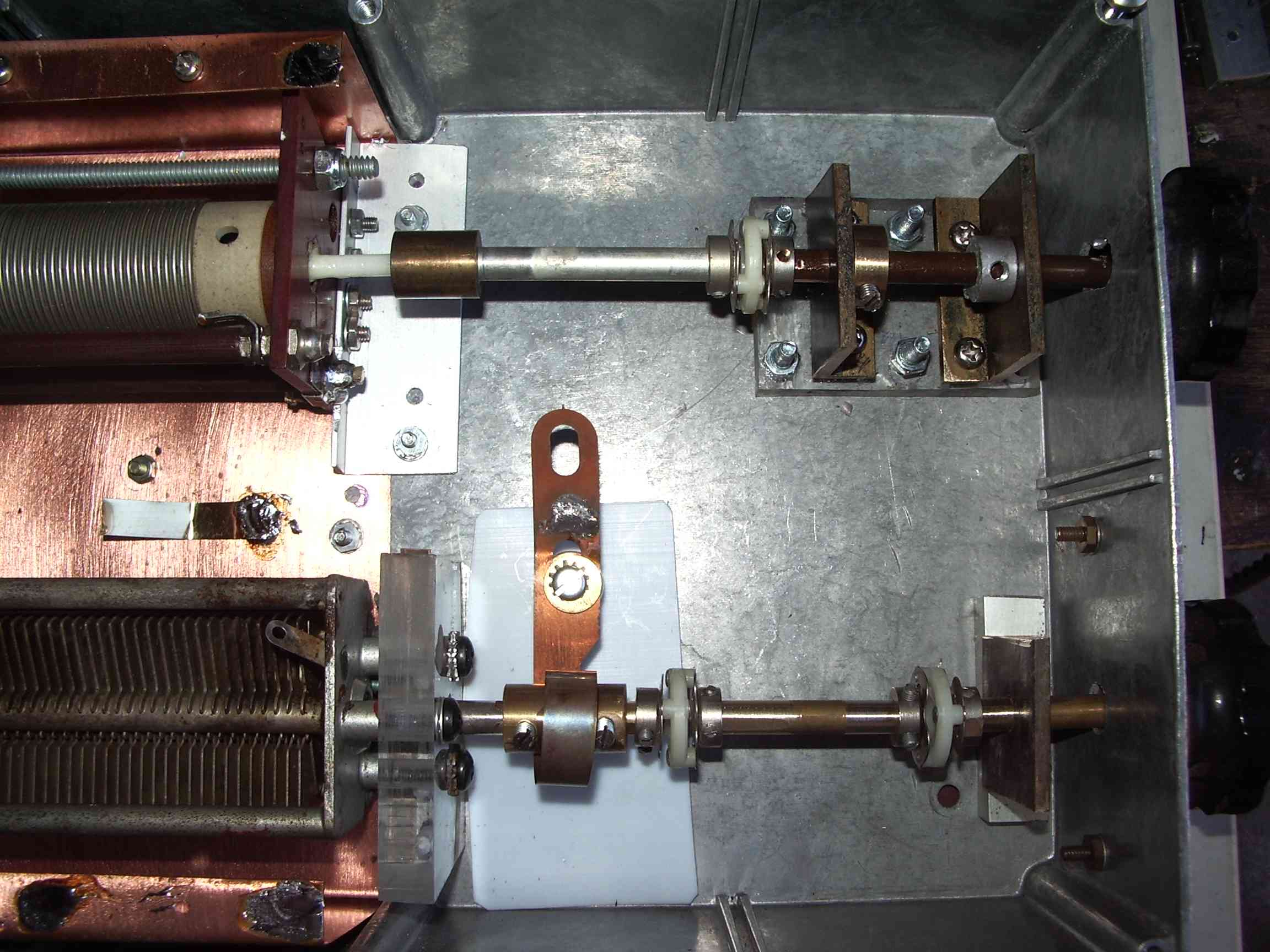

screw driver adjustment only. There were no proper bearings so the

mechanical arrangement exists so as to remove as much mechanical stress

on the bakelite on bakelite journal bearing. The flexible coupler was

required because lacking a lathe, my centering on the drive shaft is

less than concentric.

An excellent source of fiberglass rod material is the inner strength

element from heavy fibre optic cables. This material is also excellent

for use as a contact cleaner or spot polishing tool, indeed the local

electronics shop sells just such a tool which is nothing more than a

short length of this material.

The variable capacitor is one I picked up from a mystery piece of WW2

vintage radio equipment from a hard rubbish collection over thirty

years ago. It has been in assorted projects of mine that came and went

but I suspect that it has found its final home in this equipment.

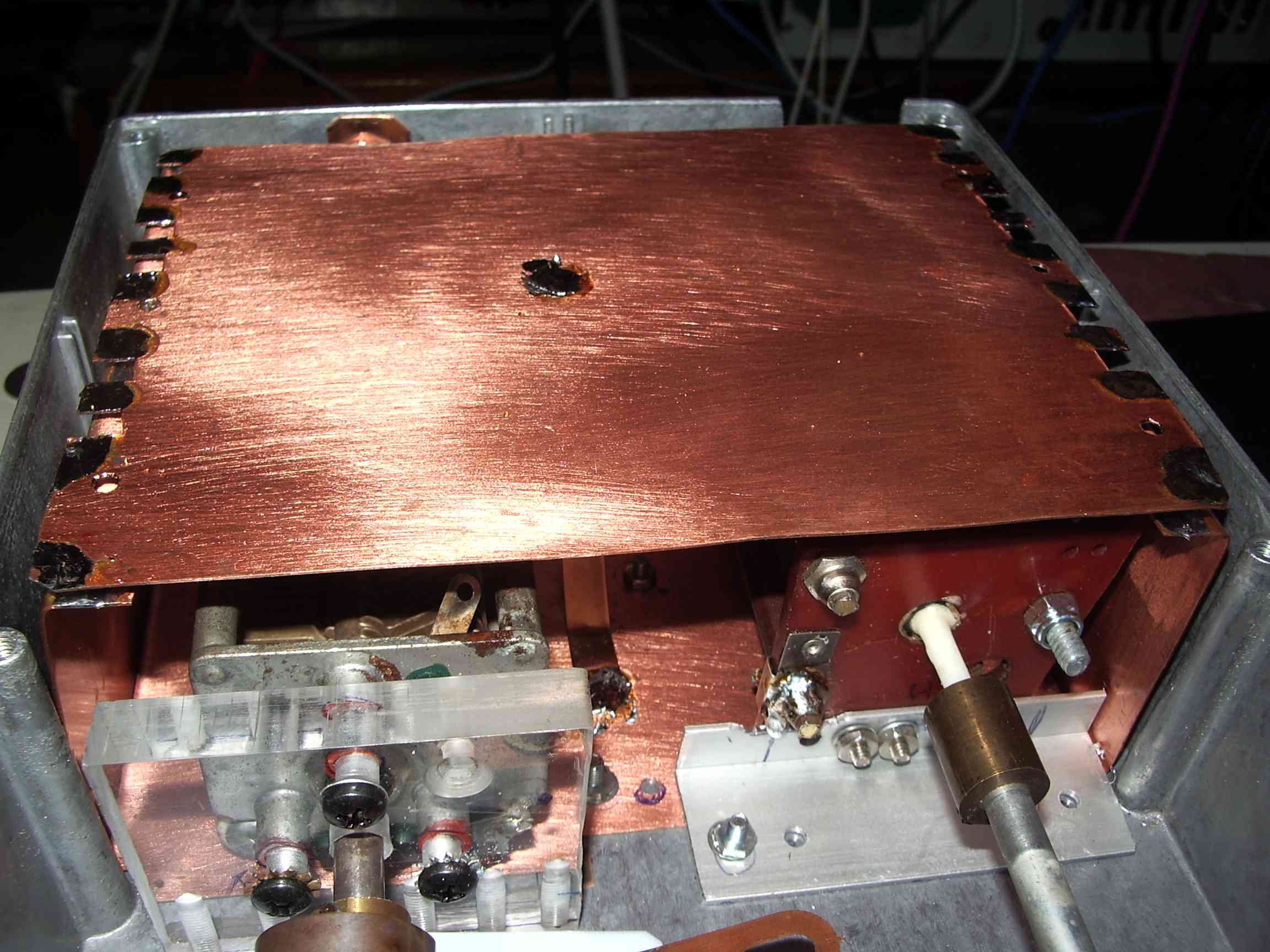

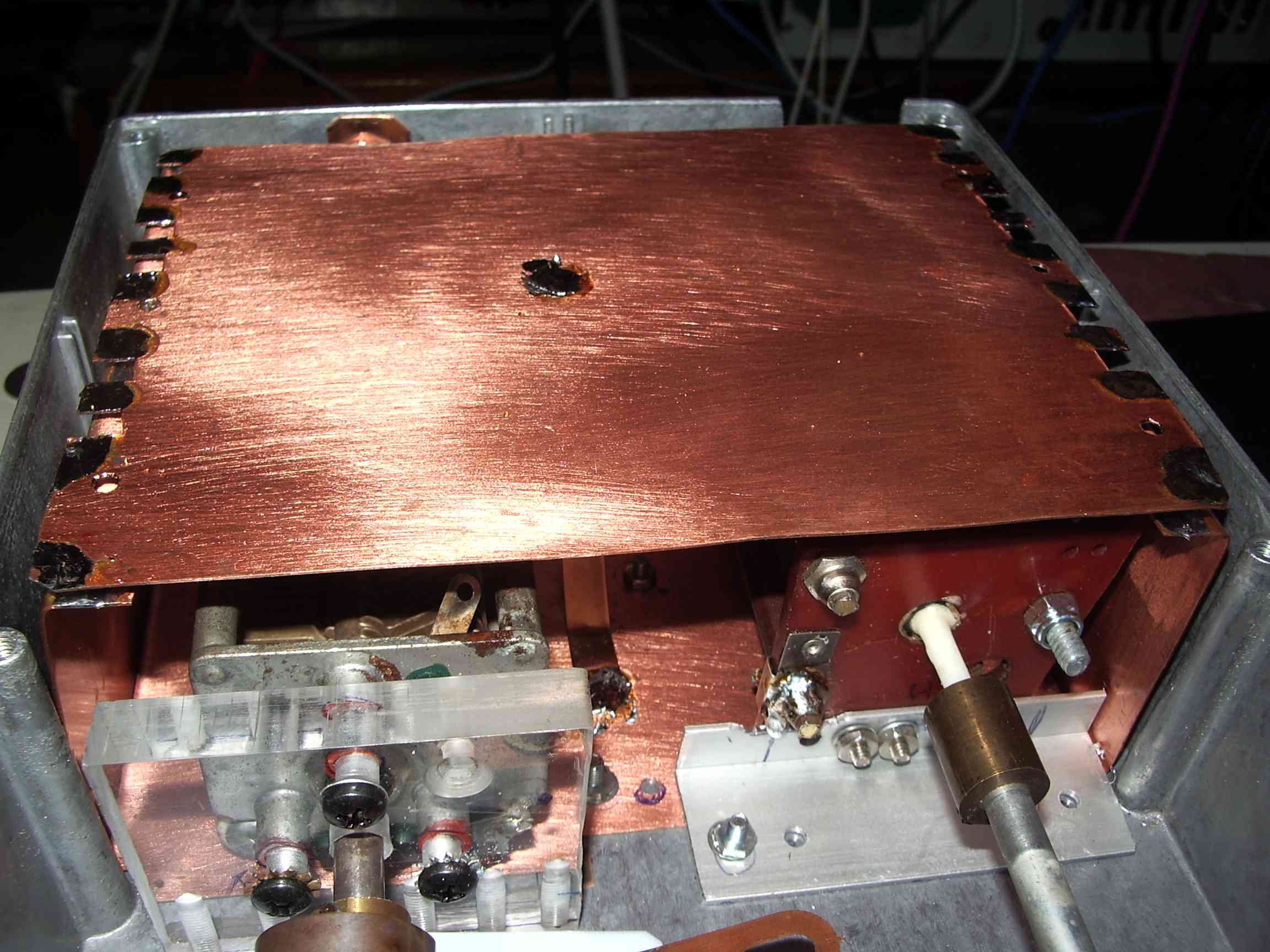

This ATU is put in a mystery die-cast

box, another castoff. The business with all the copper sheet is

motivated by the cylinderical roller inductor. It wants to induce a

current that would otherwise circulate in a very lossy path, through

the die-cast metal (zinc+rubbish), and through a dubious lid

connection. If the circulating current had a nice low impedance copper

path, that would mean extra precious Watts would make it to the

antenna. The copper sheet was recovered from a dead copper header tank,

otherwise copper sheet is now prohibitively costly.

There is an extra refinement, I did

not want heavy RF circulating currents to go through the shaft wiper

and bearings of the variable capacitor, so the entire capacitor frame

floats and the connection is made by a flexible copper strap directly

to the shaft, so there is no sliding contact. Sliding contacts are

unavoidable in a roller inductor but at least the sliding contacts are

precious metal plated.

The flexible shaft couplers are made from Unobtainium and this project exhausted a lifetime collection stock of them!

A good source of copper sheet could be the long dead dead electric hot

water service in your roofspace. Hobby shops can sell you small copper

sheets, which at the asking price is weight for weight more expensive

than pure Silver!

The bearings for the rotating

elements are made from brass angle stock. In general, I now find

that when building RF projects into aluminuim and especially die-cast

boxes, the ground areas under coax connectors and any elements that

should be grounded to a low impedance RF ground ; should be soldered to

copper flashing. You cannot trust a ground to zinc or pot metal

die-cast material. Notice what is underneath the BNC connectors.

It does make a differance.

homepage

mod record

added email sig Tue Nov 3 17:31:55 EST 2009

;

;  ;

;

;

;

;

;

;

;

;

;

;

;  ;

;

;

;

;

;

;

;

;

;