The

China Cabinet

designed and constructed by the author circa 1991

a project that

became a monster

designed and biult by Ralph Klimek over a three year span

now contains some lost souls

This China Cabinet began life as a simple request of she who must be

obeyed.

She merely wanted a small, modest cabinet in which to display

her brac-a-brac. As for me, being a little inexperienced in the

art of fine display furniture immediately overestimated its size and

the fact that cost scales exponentially with size. Coupled with

my (at this stage in life) desire to please her every whim. I also

grossly underestimated the construction time given my lowly skill level

and that I was not a full time cabinet maker !

I set about with a will. The project dragged on for just over two

years, I was fed up with it and the boss was getting cross. I

finally finished it to the point of enamelling it, then came the ugly

part. Parting will all that money to buy the glass and mirrors . I

had no idea that glass and mirror could be so costly. Despite

numerous setbacks, including a mid project change of specification, it

was completed and looks quite good, excellent in fact.....from a

distance. By and large the project was a success despite my lack of

skill and the boss's discouragement. I do not advise anybody to

replicate it, it will break your heart and bleed your budget.

This was constructed with the aid of a Triton Work Centre, I could not have made the precision wood cuts any other way.

In a dark room with its built in lamps illuminated, the effect is stunning...at least that early vision of mine came good.

The construction method is un-orthodox. First a frame was

constructed with corner joints nicely morticed and interlocked. The

frame material is heavy oregon square beams. The top is high density

chipboard placed in a rebate on the top frame, as it the very bottom

shelf. The shelves are dowelled parallel pine boards and rest in

mortices in the frame. The interior is very uncluttered and spacious as

a result. The back board , a large heavy plywood sheet, sits in

its own rebate in the frame. Glass is sitting in its own rebate and

loosely held down ( to relieve stress) with handmade beading. The three

sheets of mirror also sit in their own rebates, loosely held in place

by the back board.

The unit as constructed is immensly heavy. There are permanent

handles at the back to facilitate moving it. I now wish that I had

incorporated heavy duty castors into the design of the feet, it would

have made construction and transport so much easier.

The oregon

material has proven to be very stable. It is easy to cut, plane and

polish. It is easily shaped with a router. It is quite stable with

respect to humidity changes. I wonder why this timber is considered "

not suitable" for furniture ? Given its near immunity to vermin attack.

Mirrors are a very effective way of improving the visual appeal of any size cabinet....and they cannot be painted beige!

Electric lights are fitted, using reflector globes pointing backwards,

to remediate direct glare. Paint was (at the time) very costly British

Paints Black Enamel , when this was still a genuinely good brand.

The doors and made with interlocking morticed corners secured with a

hidden steel bolt to resist the turning moment induced by the large

mass of the doors. The glass sits in its own rebate and secured in place with aluminum strip.

At the time the frame corner joints were true and perfect, the gaps

being nicely filled and enamelled. As the years have progressed and

wood reacts to the changing humidity, the slight movement has resulted

in the joins becoming visible. If there is a next time, I would hide

the joins with a decorative cut line done with a router, so that the

joints become a feature disguising the joins.

There is a front foot, offsetting any tendancy to fall forward , as

this unit is extremely heavy. The major cost of this project was

dominated by the cost of the glass and mirrors and my time. Even though

it should be considered a success, I shall not attempt anything

this ambitious again. Life is too short; affection too fickle.

| detail images from the china cabinet project |

|  |  |

| Detail view of top LH corner. Note the not so well hidden join lines | The front foot . The foot gives it great stability | The glass is held in place by aluminium strip in its rebate |

|  |  |

there are 8 of these back reflector bulbs

these bulbs are the same as actors make-up mirror bulbs. they are very effective in this application | Detail view of top RH corner. Note the join lines on the top beam

| shelves are morticed into the columns

made from dowelled pine boards |

|  |  |

| The front foot . The foot gives it great stability | the back of the cabinet is lined with mirror. This doubles the effective visual volume of the display | just

visible is the hidden bolt securing the door frame Hidden bolt is

no longer a secret! This joint method is very strong. |

|  |  |

|

detail of top LHS corner. When made, the joint lines were not visible ,

but over 15 years as the wood slowly heaves the joint is outlined. Also

seen is the home made beading holding the side glass panels against

their rebate | Interior view of front corner. The white blemishes come from the plastic material contents on display | detail of door posts joining the main roof beam. This joint line should have been hidden with a better mortice joint |

I believe the white powder that has

grown on to the orginal gloss black has come from plastic objects that

have been displayed over the years.

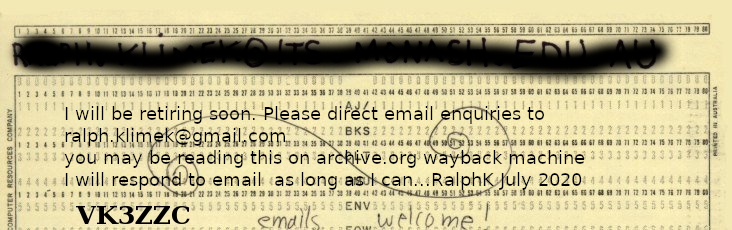

homepage

mod record

Fri Nov 20 19:36:28 EST 2009

page formatting improved, extra text and images