The Escritoire.

Ralph Klimek 2005

abstract: restoration of a

mystery "antique" desk, solid cedar wood, biult by an apprentice, a

tragic fault with the original construction was repaired, amatuer

woodwork

This desk was not made by me,

it was a restoration project and a small spiritual quest as well . This

desk was discovered on a council hard rubbish collection, looking sad

and forlorn in the rain, other discarded bric-a-brac suggested to the

impressionable a deceased estate's junk. I noticed that the wood was

naturally dark, it was solid wood, not some rubbishy laminated

chipboard. The wood was cedar! Golly ! This kind of wood and planks of

the size this desk was made from are simply unobtainable today. The

desk was broken and would need restoration and TLC before use. It was

"antique" in some superficial way, my guess that it was made before

1950 based on materials used, but I dont truly know its age.

The desk was first noticed by she-who-must-be-obeyed and I

think

she was attracted to the rare and precious wood in its

construction.

The desk and its construction faults intrigued me. It was a mixture of

ineptitude and professional expert skill. My deduction about its origin

is that it was constructed by a wood working apprentice possibly in a

technical school as an exercise piece or even master piece possibly in

the forties or fifties when cedar wood was still available. The use of

cedar for educational use is indicated because it is so easily worked

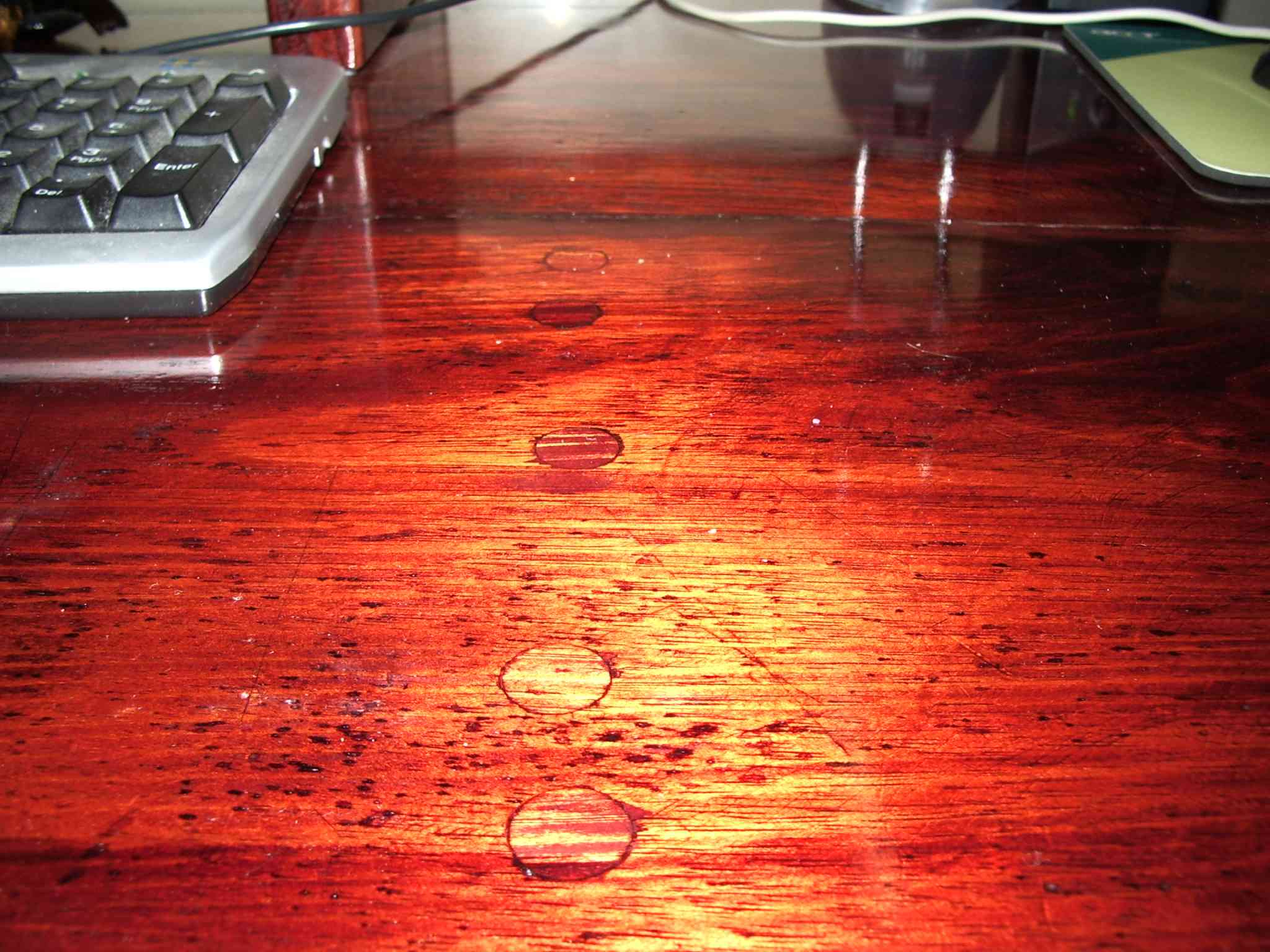

with hand tools. There were no markings, only layout lines, old

graffiti and deep scratches, this desk had also clearly served time as a garage

bench.

The structure of the desk had a very major defect. It is made from two

very wide dowelled parallel boards. The boards would have been hand

planed to mate perfectly. Over the years , perhaps even during

construction,

because the original wood had not been seasoned long enough,

both of the boards had bowed in opposite directions resulting in a

very large gap

in the desks top surface and totally spoiling it. Some attempts had been

made

to arrest the crack caused by the bowing by a previous owner or the builder

but these had obviously failed. I faced now the same problem, unless I

could close up the crack or reverse the bowing this poor old desk was

doomed. I can only feel for the student who built this, it must have

been a terrible disappointment as the residual and irresistable

forces in these two planks slowly ruined his work, maybe even just

before completion when it was too late to redo it.

Reversing the bowing was out of the question. I tried with sashcramps

to force it and then bind the crack closed but the force was equivalent

to several tons and nature cannot be fooled like this for long. I was

forced to follow the path of treating the the crack which at it widest

was nearly 4 mm, far too much for putty and anyway, filler would have

looked ugly under varnish. I was not going to paint it, no way.

There were remnants of putty in the crack from previous attempts to

remediate this problem. Rare wood deserves to be shown. The fix was

inspired by dentistry. I would recut the board in situ until both

internal edges were parallel and then with sash cramps force

the

halves to mate. I used a jigsaw between clamp-on guide boards to clean

up the crack and then by cutting, forcing, cutting , forcing until the

two edges mated perfectly. The hidden wood screws that held the

structure together had to be be found and cut to permit this. The wood

was used as is with its aquired bow now accounted for.

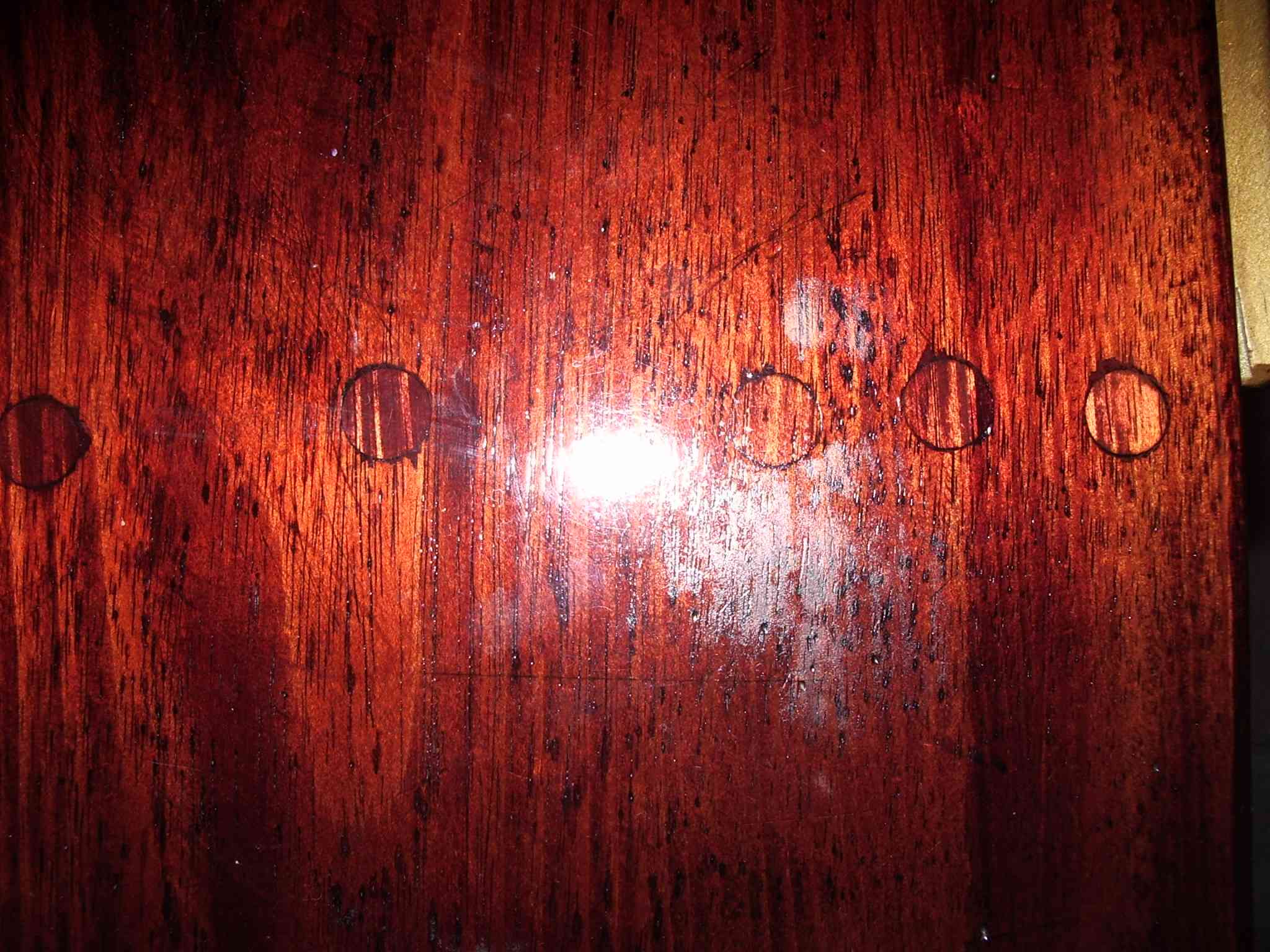

Finally I had the two surface boards mated perfectly. To be sure , the

hidden undersurface has cross beams installed that are heavily screwed

and glued to arrest any further tendancy to bow. The wood screws that

bound the top surface to the under structure had been expertly hidden,

now that they were cut and now offset by the forcing operation I had to

learn how to hide new and old screw holes to give a perfect top

surface. Luckily the local Bunnings sold me a plug cutter. I had a

small piece of the cedar wood used in an unseen part of the desk which

I used as a source of plugs. The resulting hidden holes were excellent

to merely good. I nailed this piece under the desk in case some future

restorer long after I go west needs it too!

With the structure now sound and other minor structural defects made

good I added a hidden mystery shelf just behind the front top surface

and turned my attention to the drawers. They had originally been

finished with a very high quality rare wood laminate. This had over the

years blistered off, the original animal glue having decayed. The edges

of the laminate had suffered physical abuse. Most of it was still

serviceable. It has been originally finished in dark french polish and

a hint of its beauty still remained. I routed off the damaged edges and

filled the resulting gap with treated pine sticks. This gave it an

interesting visual contrast. The draw handles are original, I was

astounded to discover that under the years of gunge, old paint and corrosion they

were solid bronze ( not brass ) and assuming you could even obtain them

now they would be prohibitively costly for any new project. They

polished up beautifully.

At the bottom floor facing edge, there was splintering and tearing of

the wood were in the past it was dragged over carpet, I added a angled

brass strip here, so now the unit rests on a brass strip and can be

safely dragged over the floor without further risk of splintering. The

brass bar looks good too. I should have rebated the brass angle

stock in, perhaps in 10 years time it it gets to be revarnished,

and by then it will get castors too.

The desk was finished in stained polyurethane varnish and has a piano

grade finish as by my method outlined elsewhere. The metallic

decoration in the front board is a silver plated brass tea pot stand!

that I embedded into the wood. She-who-must-be-obeyed decrees that I

put it in the wrong way round. Go figure.

One question that I still ask myself is; could I, instead of

effectively rebiulding the desk to remove the crack, could I have

hidden it with an inlaid strip ?

In retrospect I should have tried

this approach. Would it have been as effective a remedy ? Inlay is hard

and I did not have any similar material on hand. I have never tried the

art of inlay on a real furniture piece.

Somehow I felt on completing this project that a ghost was exorcised, its

perplexed builder now rests a little easier.

|

|

visible here is the back kickboard. The little shelf at the back does

not appear to be part of the original design but must have been placed

there later by the builder because the wood stock is the same as the

table top. The draw laminate was badly damaged on the horizontal edges.

I routed them off and fitted these treated pine sticks to make good. I

dont know what the laminate wood is but it was probably costly. The

bronze handles were hiding under a thick layer of old paint and gunge. |

|

| The front ornament. Originally

a brass teapot stand! There is a secret shelf behind this panel. |

|  |

| Side panel bracing. This was to arrest a split . | Table top bracing to arrest further bowing |

|  |

|

My sorry attempt at hiding screw holes. | The

table top gap has been closed |

|  |

|

Deep scratches earned from its garage bench career | The new brass foot. A rip in the left board is visible |

|  |

| One of the screwholes is invisible. Its the third one up | Hand cut dovetails. pencil layout marks are still visible |

All in all a successfull project. Some things to do better next time.

The Vermont American plug cutter has a design defect. The surface

on which it rotates has a rake clearance angle of zero. This results in

excessive friction causing burning on the circumference of the cut

plug. I should regrind it to give it small small measure of clearance.

Maybe the plug should be cut under water ? Some of the hole plugs

were very good indeed. This is a skill worth developing in the future.

I should have added castors. The decorative front board serves to

hide the secret shelf and provides bracing for the tabletop. I should

have used a finer grained timber stock for this. Its a piece of mystery

wood from a packing crate. The original was a thin cedar

board, same material as the tabletop, which I used as a source of

material for cutting the plugs. Maybe, instead of forcing the

original tabletop crack closed I could have made the crack regular

and inlayed a wood or brass strip. That was and still is beyond

my skill.

The project time for this was about three weeks total worth of my infinitisimal allotment of personal time.

home

mod record: updated using tables Fri May 9 18:15:10 EST 2008

copyright: none this article is copyleft, do with it whatever is your will, no rights reserved