underspecified electrolytic capacitors,

a new paradigm in electronic planned obsolescence

a rant by ralph klimek

2-jun-2009

keywords: bulging electrolytic capacitors, ESR, equivalent series resistance,rant

This

rant's subject concerns the usage of electrolytic capacitors in power

supply smoothing applications to enforce planned obsolescence

strategies in both professional and consumer grade electronic equipment.

The

subject matter of today's rant was inspired by the slowly

degrading performance of equipment that I maintain at work. The

equipment is supplied by a leading manufacturer of networking

equipment. I have no quarrel with the vendor, they have done the utmost

to help us and will accept and replace damaged equipment without

arguement. I think they are the innocent party in this problem, so I

have taken pains to ensure that they cannot be identified by my rant. I

have also replaced a number of damaged capacitors on expensive computer

PC motherboards , restoring lost reliability.

However, I decided

to mount my soapbox when I found this very nice PC ATX power supply in

the dumpster. It appeared to be almost new, it was the advanced

atx model with sata connectors and the new wide atx motherboard

connector, a desirable item. What was it doing in the rubbish ?

Knowing from past experience that good things are discarded . not for

lack of function, but because they are no longer bright and shiny.

I took it home and put it on my dummy load. It powered up

for a few seconds and then crowbarred, ie, the overvoltage alarm had

tripped and shut down the primary inverter. This power supply was

effectively dead, but not irreversibly so. At least not to me.

There

were no obvious signs of burnt out components and a quick multimeter

pass revealed that the inverter transistors, fuses, diode et al

were good. I then noted one peculiar thing. There

seemed to be very few electrolytic capacitors on the low voltage

output side. Good design practice dictates that the 5V rail

have not merely one but 5 or 6 capacitors in parralel. The reason for

using so many is because of the high current spikes that are coming

out of the step down transformer and shcotky rectifiers are of

many tens of amperes of peak current. Your logic circuits dont

want this kind of rubbish, they prefer nice clean DC please. Real

electrolytic capacitors have a parasitic resistance that is frequency

dependant, electrode geometry dependant and electrolyte dependant. This

parasitic resistance is real, and, being real, really turns amps into

watts! These high current pulses heat these devices. You

put many capacitors in parallel to spread the quite onerous burden of

sinking these multi ampere pulses.

Electrolytic capacitors are sold with two primary specifications, maximum sustained working voltage, and capacitance.

There

are other specifications, sometimes published by the vendor, usually

not, and that is equivalent series resistance, (ESR). For simple

smoothing applications , for example, linear PSUs (plugpacks et

al), audio frequency coupling and decoupling, electrolytic caps

can have moderate to high ESR and work perfectly fine for

these applications and have an arbitrarily long life if their voltage

rating is respected. This life can be thirty years or more. I

have seen fifty years life in some pioneering equipment.

Modern

switch mode power supplies with their extreme pulse currents demand low

ESR devices. These first become available about 30 years ago with the

first generation of switchmode regulators. The equivalent series

resistance is never indicated on the device itself, unlike the voltage

and capacitance rating. It is only ever specified in the manufacturers

data sheets...if available.

Like

all electronic

components, the power dissipated, temperature and lifetime relationship

is well characterized and governed by some simple rules of thumb,

allowed for by statistical analysis. The general rule of thumb is

that for every 10 degree C increase in operating temperature, the

average lifetime of an commercial electronic component is halved.

Devices supplied for defense or advanced commercial needs are

very tightly specified with temperature derating curves and accelerated

aging testing that can reliably predict device lifetimes given a

service temperature and operating condition. Are you smelling a

rat here ? Put on your tin-foil hat. I recenly acquired a

capacitance meter that could measure electrolytics precisely, by timing

how long a charge took at constant current. It revealled the

obvious. A ruptured electrolytic has lost over 99 percent of its rated

capacitance. One that had merely bulged, but not actually

ruptured, had lost anywhere between 50 to 90 percent of its rated

capacitance.

I

have recently come to the conclusion that the cause of the "bulging" is

due to the absence of one key stabilizer in proprietary electrolytes. I

believe ( without proof ) that the missing ingredient is a gas

recombination catalyst. The gas is hydrogen and oxygen from simple

leakage current induced electrolysis. That catalyst is most

likely a trace of platinum or palladium. That alone is sufficient

economic reason to exclude it !

The conditions under which

"low ESR" devices must labor are onerous. The thermal conditions

inside the average consumer PC PSU are particularly onerous. The

pathetic excuse of a cooling fan serves only to exhaust pre-heated air

from the PC enclosure to the outside. You cant cool

something with hot air, unless your thing that you are trying to cool

is hotter already! Power electronics must be kept cool, this is not

news. An electrolytic capacitor is particularly vulnerable to

over temperature conditions especially in switchmode smoothing

applications.

some theory

The capacitance is a measure

of how much charge an object can store. It is a strong function of

geometry and material properties. The capacitance is inversely

proportional to the seperation of the electrodes. In the real world,

electrodes are seperated by air, oil, paper, assorted polymers. Such

capacitors do not have the capacitance required to perform the SMPS

smoothing

function. However, what if the seperator was an molecular

thickness of an impermiable substance...say aluminium oxide ? It

has a very high band gap, is mechnically strong, it adheres to a

metallic aluminium substrate with great tenacity. It is easy to form

and better still it is cheap!

An aluminium electrolytic

capacitor was invented in the 1920s, its nothing new. There are

two metal foil electrodes, a mecanical sepparrator , ususally paper or

now advnaced polymer mesh and a water based electrolyte, usually based

on ammonium borate and proprietary stabilizers. The electrodes

and seperator is rolled up into a cylinder, canned with electrolyte

solution and then hermetically sealed. The actual insulator is a

molecular film of aluminum oxide which is grown be electrochemical

action after the first "forming charge" is applied. One electrode

of the capacitor is the metal with oxide film, the other electrode is

the metal, it is the conductive electrolyte. The "plates" of the

capacitor being only a couple of molecules thick, and being so close to

each other, the geometry of the device now acquires a very high

capacitance and large amounts of charge can be stored at moderate

voltage.

The ESR of such a device is governed by the specific

molar conductivity of the electrolyte and the thickness of the metal

foil in the electrodes. A low ESR device is necessarily larger.

A high temperature and high voltage will lead to electrolysis of

the electrolyte and the inevitable generation of gas when the water is

broken down into its hydrogen and oxygen. A good capacitor may even

have a catalyst to recombine the gases. (that is speculation on my part)

Many

of you reading this may now be going "ah-ha!" . You will have

come across the recent phenomena of the "bulging capacitor". The

modern cap has inbiult fracture lines stamped into the little metal

can. When internal gas pressure is extreme, the can will gently rupture

and expell their contents. They used to detonate! When a capacitor

ruptures it irreversibly looses the electrolyte that is essential to

its operation. Its capacitance goes down and its ESR goes up, thus

dissipating even more power and getting hotter and hotter. The DC

that it is trying to smooth becomes noisier and riddled with

transients. Your equipment becomes intermittant, behaves like its got

gremlins, your pooter keeps blue screening untill it just stops

working. Is this familiar....anyone ? Open up your power supply

and have a look. Examine your computer motherboard. If you are

getting aberant behaviour it could be due to bulging caps. They can be

replaced, any competant electronic hobbyist is capable of doing so.

for the tin-foil hatted or the bright-young-things-with-harvard-mba

conspiracy theory one

Equipment lifetimes can be controlled by carefull selection of switch mode regulator smoothing capacitors.

conspiracy theory two

This has already happened

images of damaged equipment

|  |  |

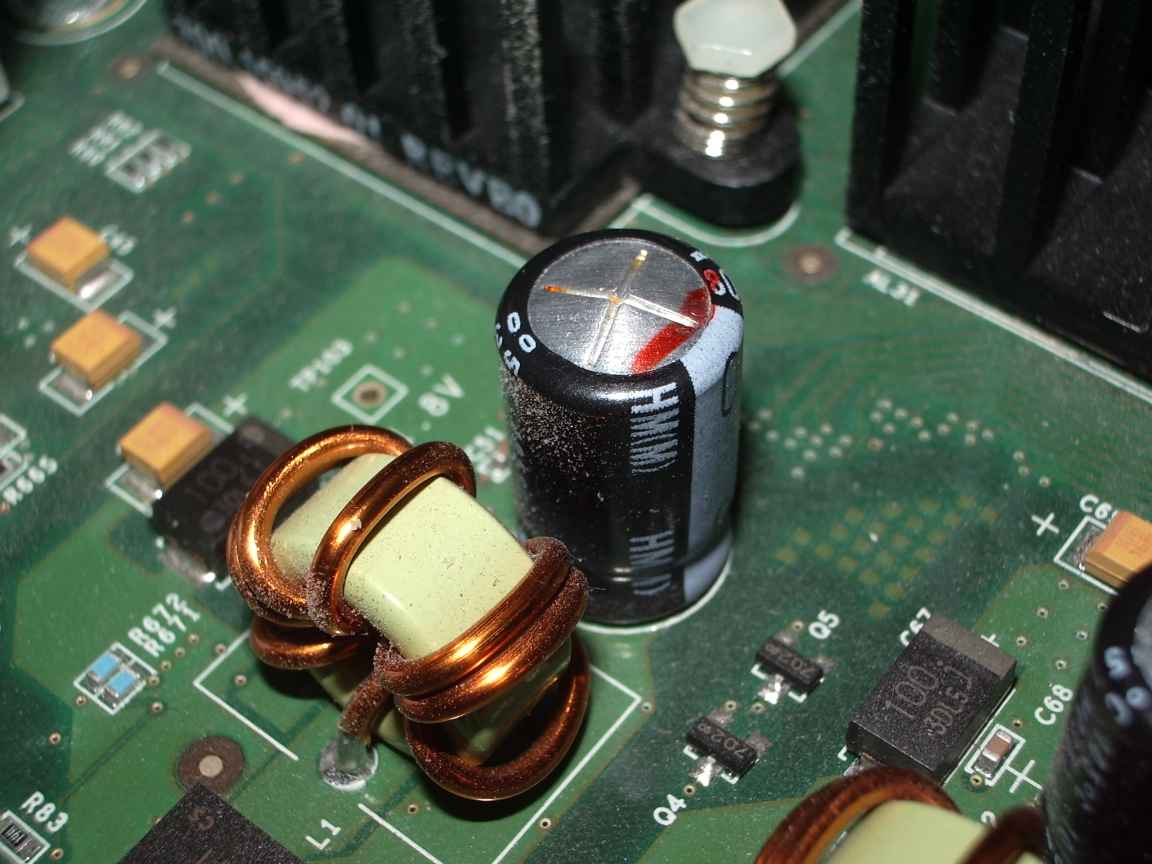

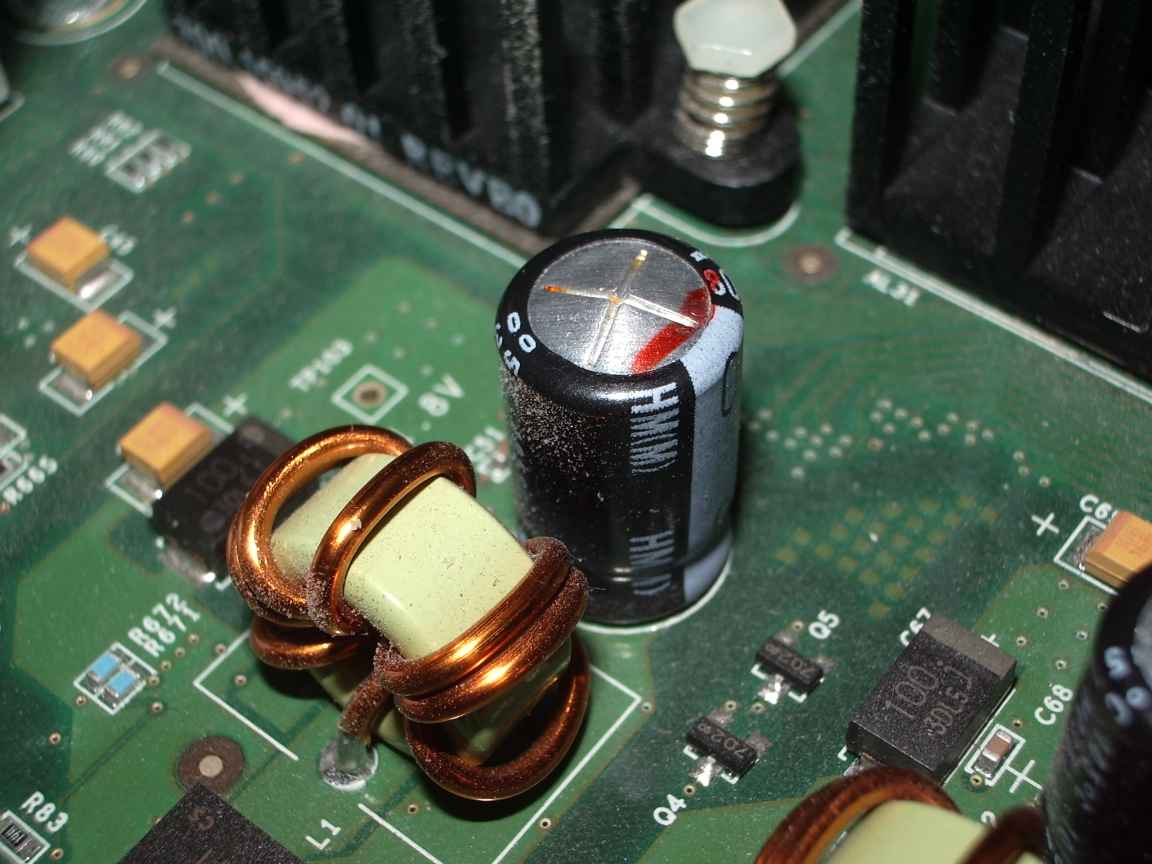

| this

otherwise well made network gear had become erratic and intermittent as

a result of noisy power rails caused by these damaged capacitors |  |

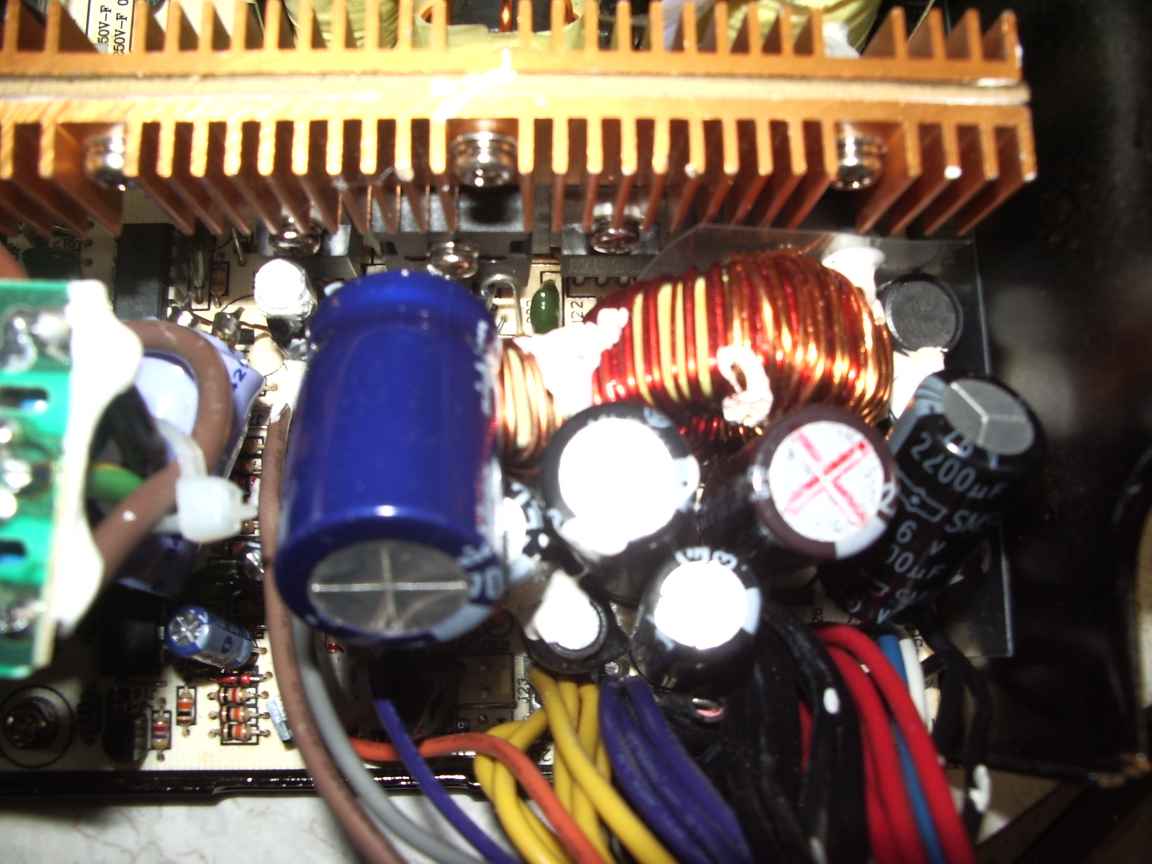

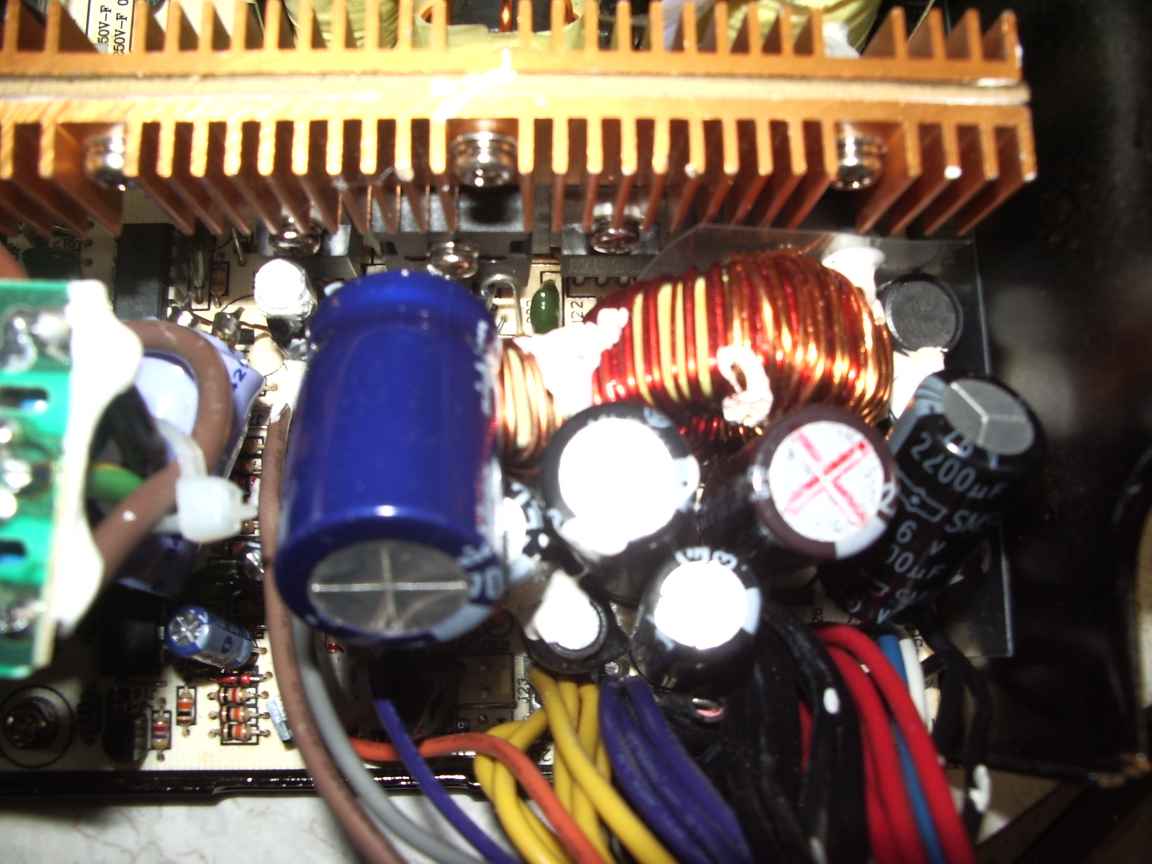

| | damaged caps from this PC PSU these have ruptured and expelled their contents |

|  |  |

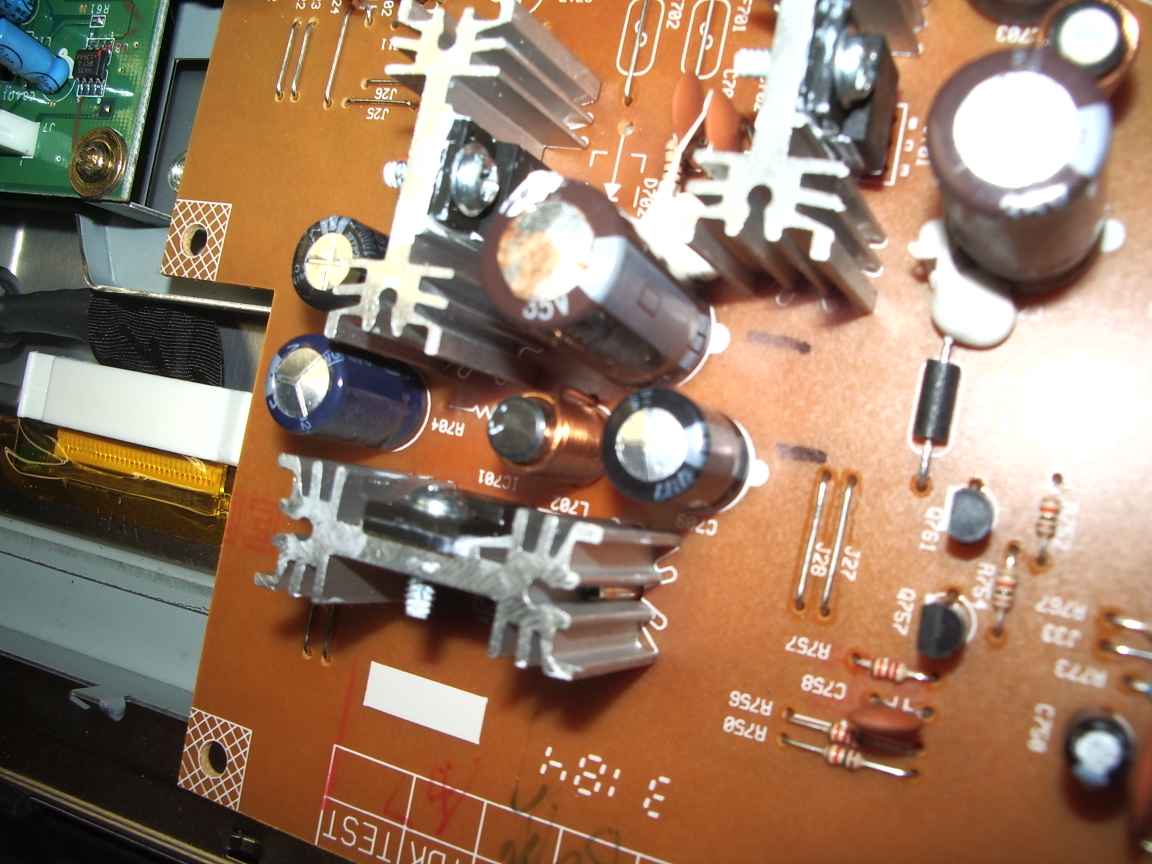

| damaged caps from PC PSU. The measured capacitance was only 150uF instead of 3300uF | after my repairs | after my repairs close-up |

| The

real question is why were there so few output smoothing caps in this

PSU. No doubt the ESR and capacitance rating was in spec when this was

assembled but it clearly did not stay working for very long. My

replacements came from the junkbox. For completeness and piece of

mind, I will be making an outboard PCB containing extra paralled

capacitors to ensure that the PC will have clean 5V and 12V rails |  |

| otherwise a really nice, expensive PSU | | otherwise a really nice, expensive PSU |

Ha

! Thats nothing. I have recently recovered some nice lcd flatscreen

monitors that were discarded because they were none functional.

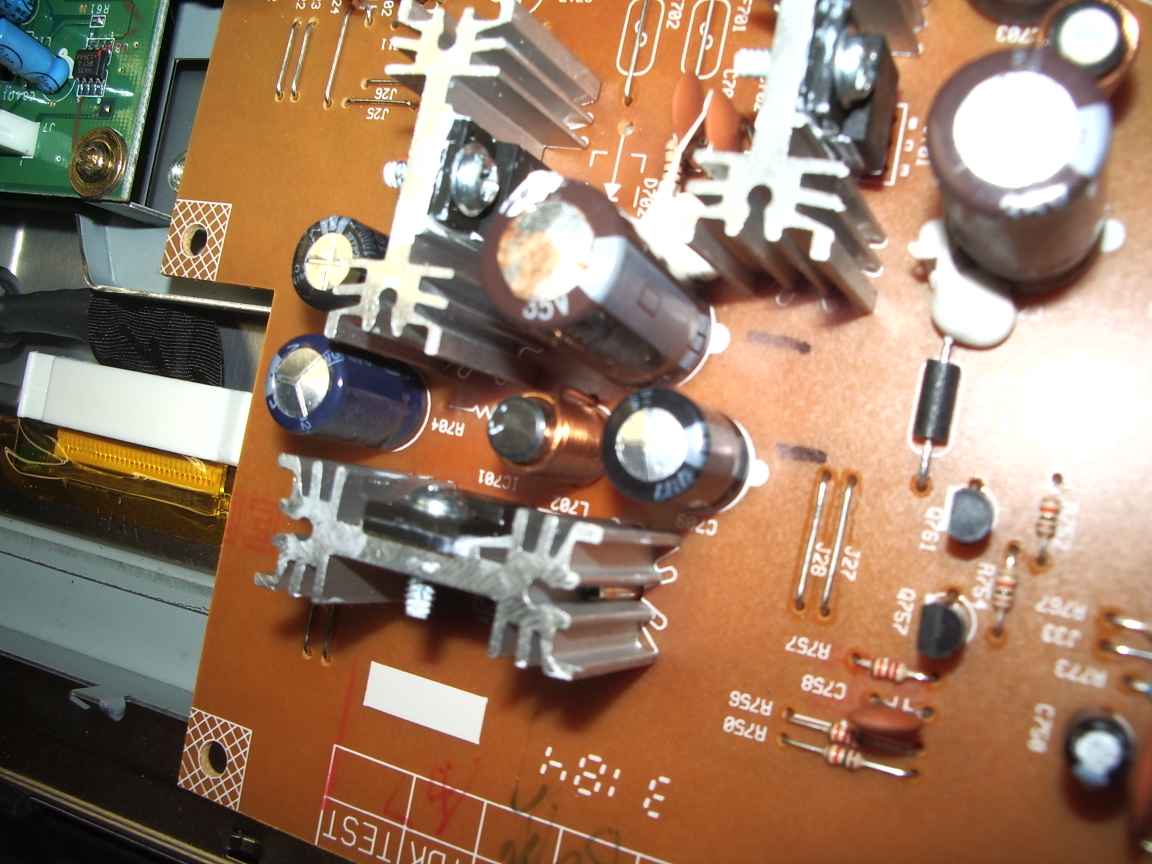

The

business part, the lcd flat screen had in all cases been carefully and

well constructed by the Japanese and Taiwanese flat screen businesses

that do this sort of thing very well. However, the power supplies had

been made by the cheapest contractor that could be found on the day.

The problem and solution should come as no surprise. These

otherwise perfectly good lcd screens were dead because of bulging

electrolytics in the rubbishy power supplies. Replacing

these has now brought an embarrassing over-abundance of good flat

screen monitors. Gosh this world is weird. Here is another

tip. If you find a discarded monitor in the dump that uses an external

power brick, the usual reason for discarding the monitor is that the

previous owner has lost the power brick, experience has shown that that is allmost never anything wrong with the flat screen.

|  |

| rear of a Mitsubishi 17 inch lcd monitor the psu board is made by Benq | replacing these 3 bulging caps got it going |

copyright declaration: none, this article is copyleft, quote it, copy it, use it as you see fit

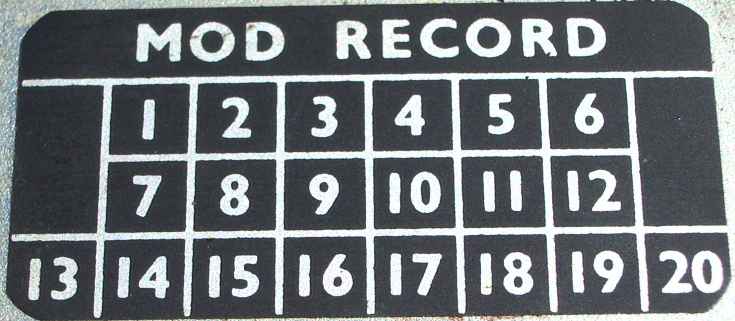

mod record page created Tue Jun 2 19:17:04 EST 2009

added flat-screen monitor image

it was a dark and stormy night...