Here are my hand drawn reversing notes. good luck. They are about 85

percent complete. I have not been able to figure out how it decided to

use single or double conversion. The switch bank wafers are allmost

innaccessible and I cannot decode them. This switching is determined by

a switchbank at the rear of the chassis underneath the 2nd if module.

The switch bank is driven by a rack and pinion drive from the main

bandswitch turret. There is enough information here to debug most

A618 faults.

second mixer module at rear of chassis using ECH81 or CV2128 with 1995khz crystal osc

part of second mixer, under chassis wiring, mixer and first if transformer

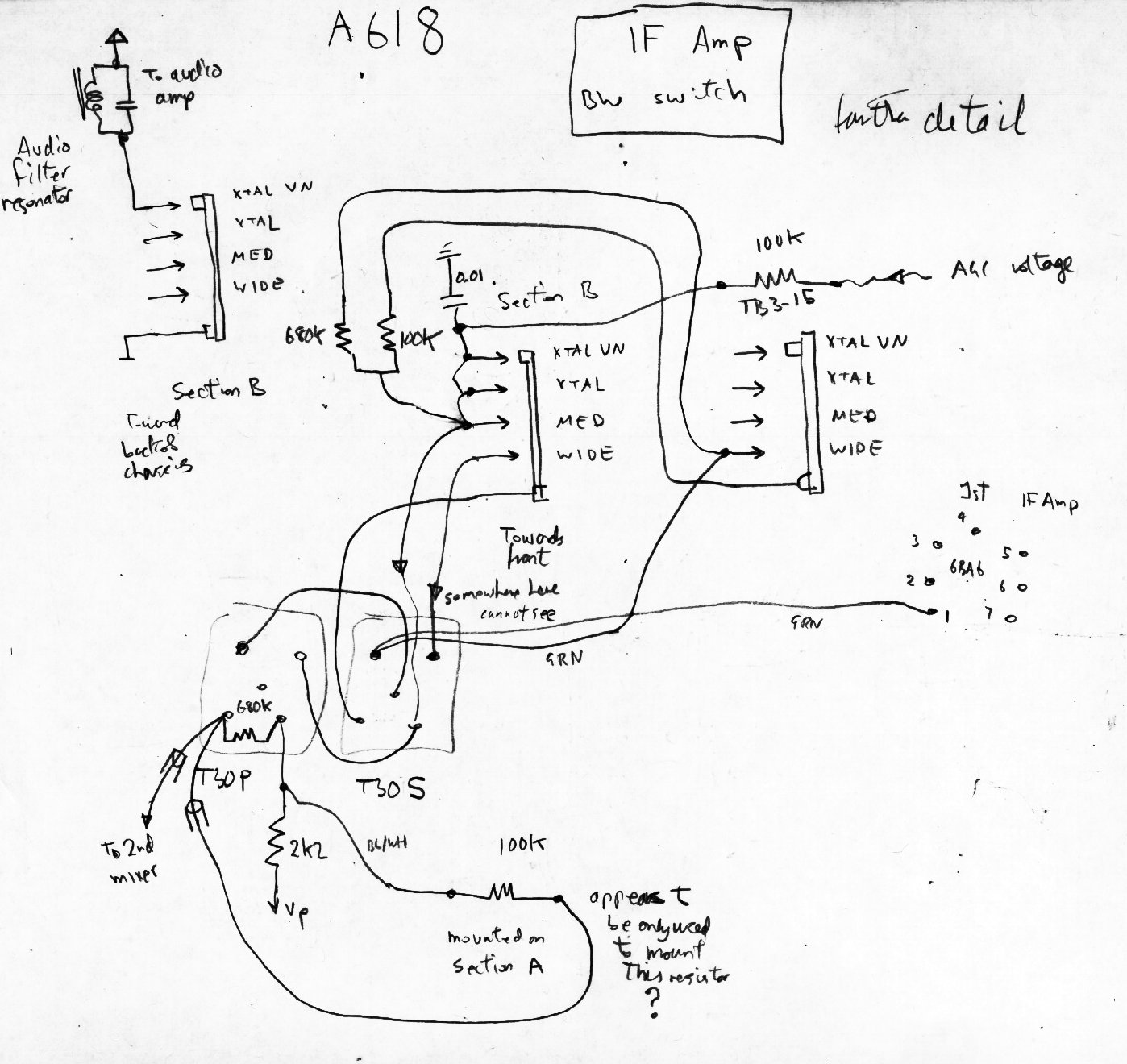

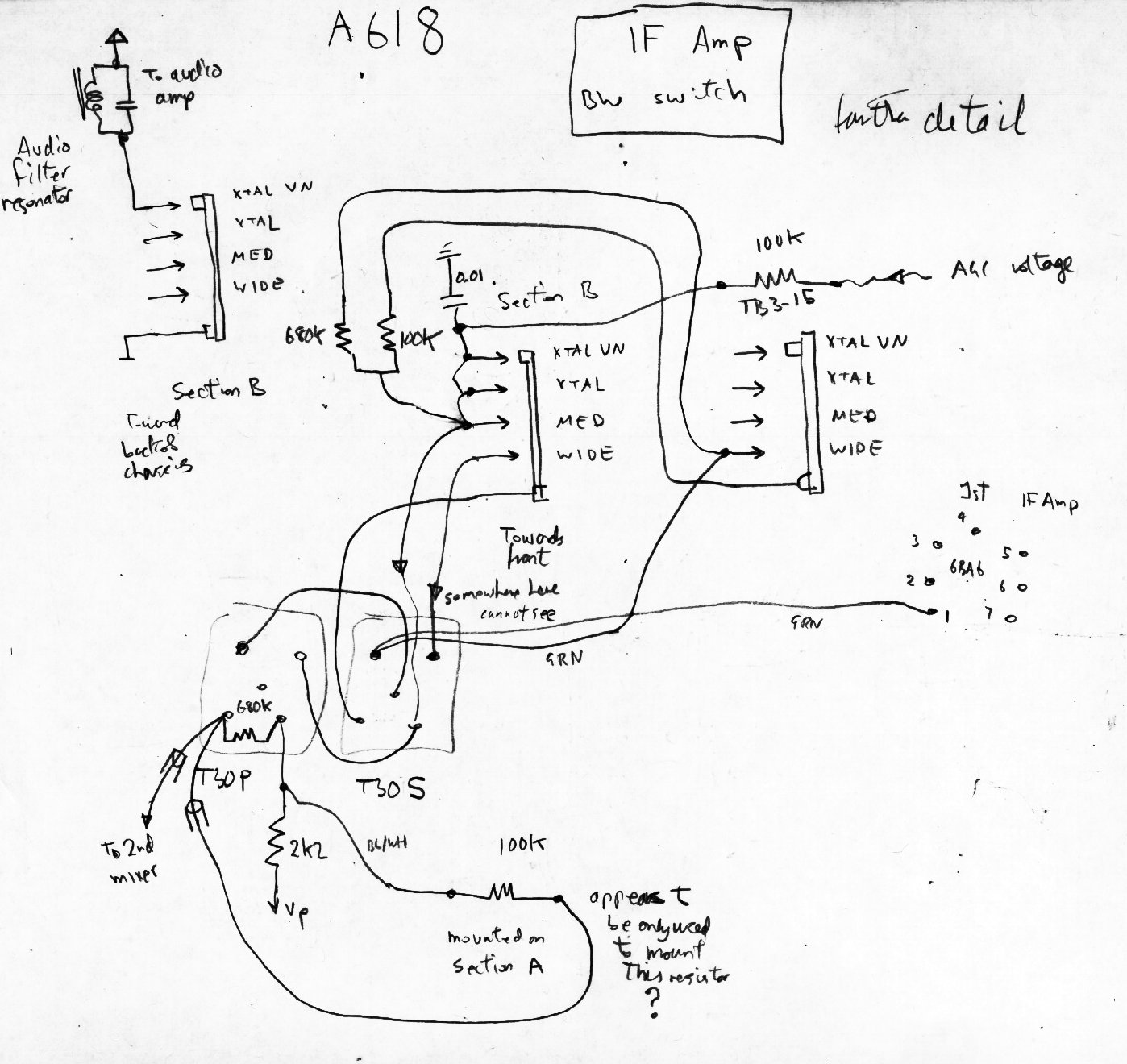

main if amp bandwidth selection wafers

This bit I dont understand. The switch bank is driven by rack and

pinions from the front panel if bandwidth control. There are 2 stages

of transformer coil determined bandwidth, one position inserting the

quartz resonator in narrow mode and in "very narrow mode" a 800Hz

parallel resonant LC filter is inserted in the audio path.

bandwidth selection wafers, very narrow mode LC audio filter is inserted here

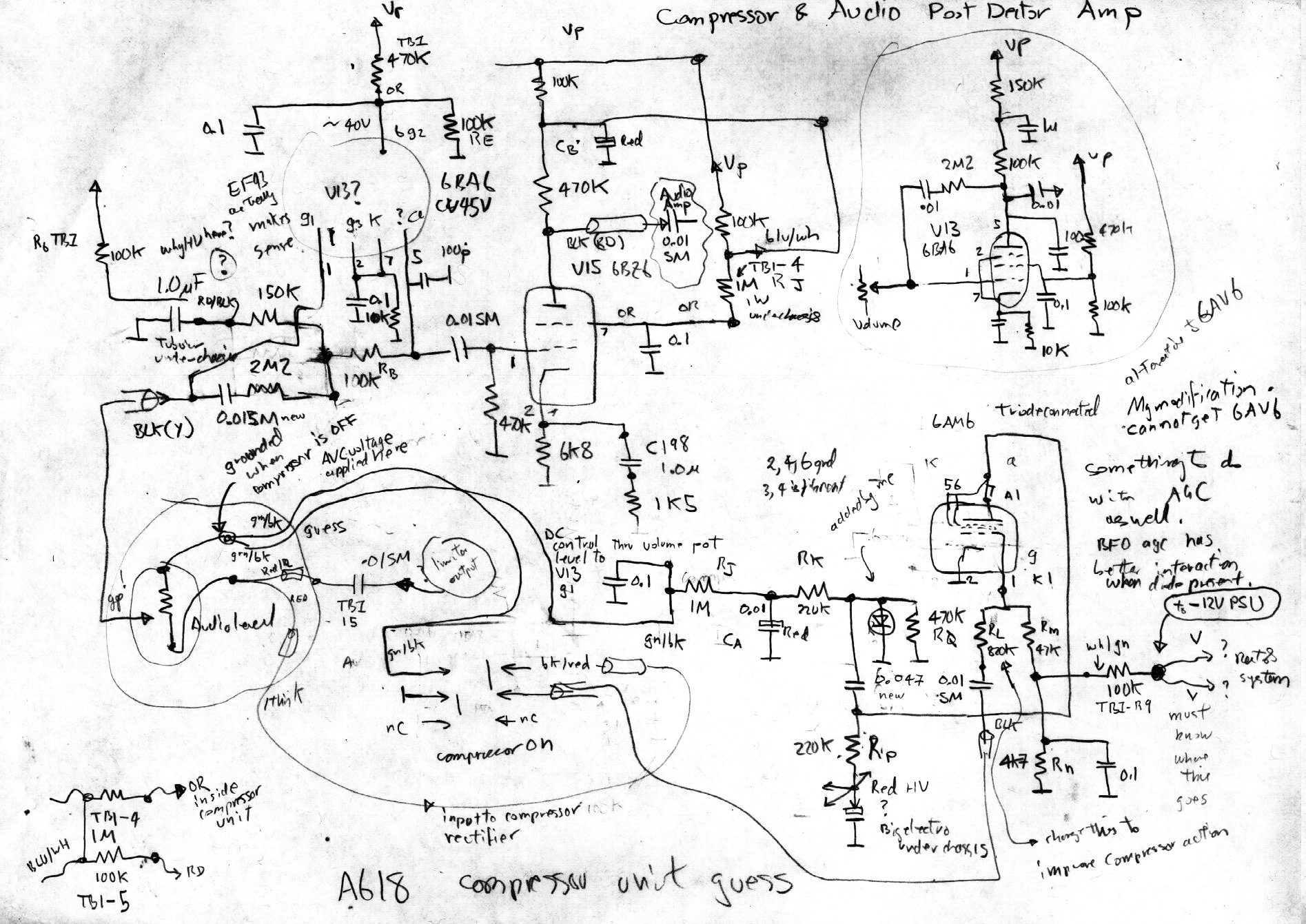

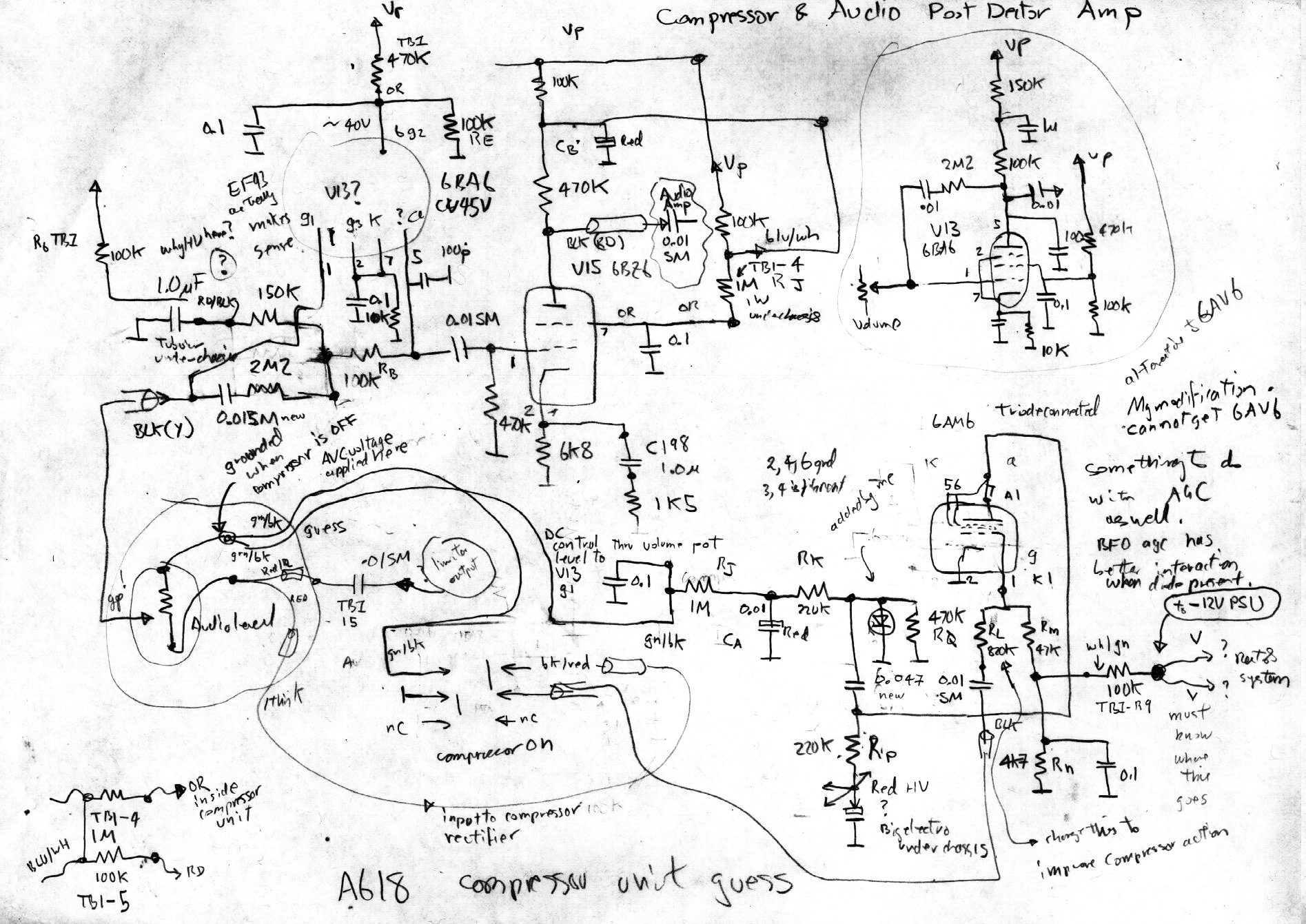

post dectector audio amplifier and compressor. see the inferred schematic below.

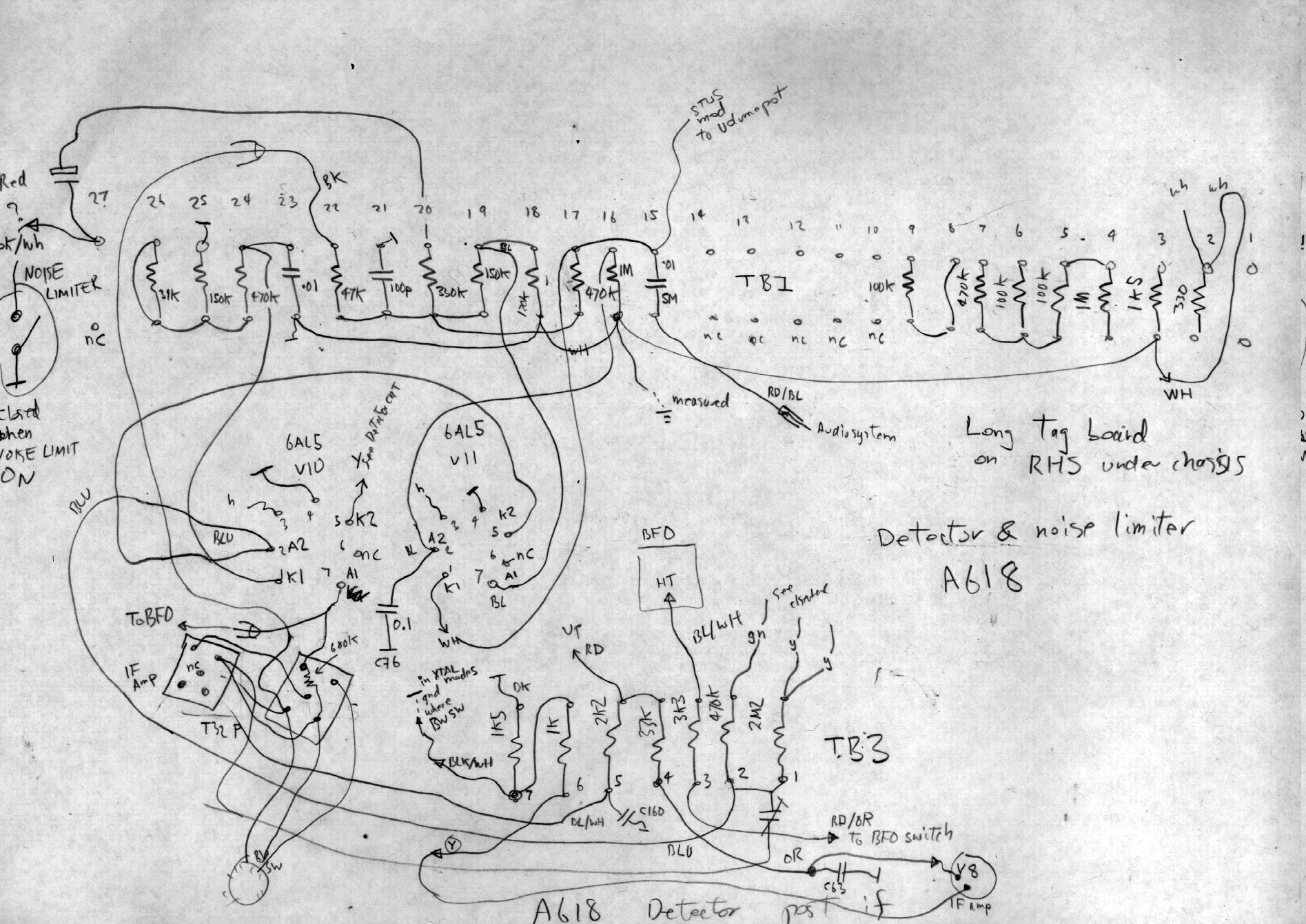

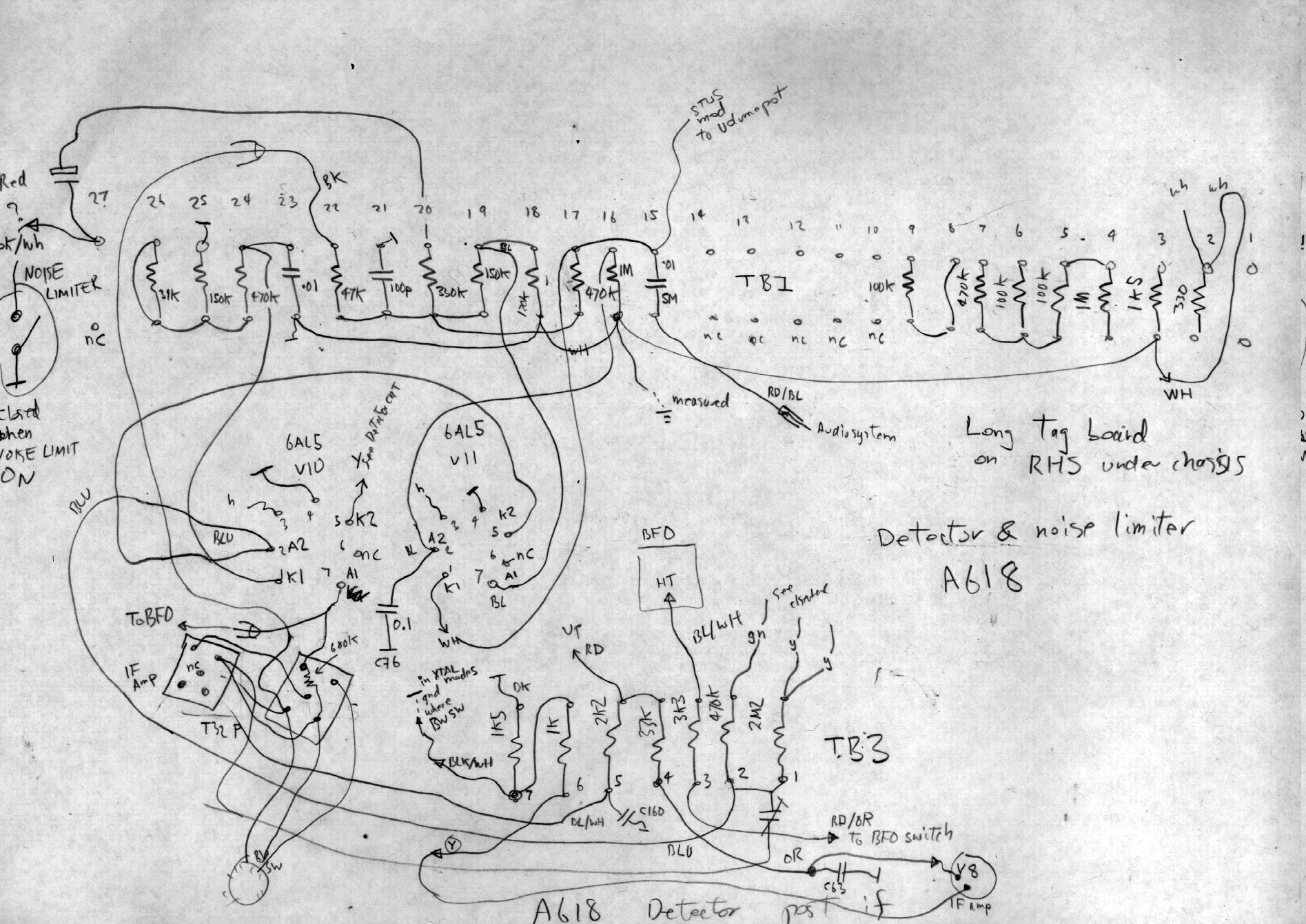

detector, agc, delayed agc, noise limiter, manual IF gain control, S meter drive

audio power amp, filter CW in very narrow mode

under chassis central tag board, detector,agc,agc control switch

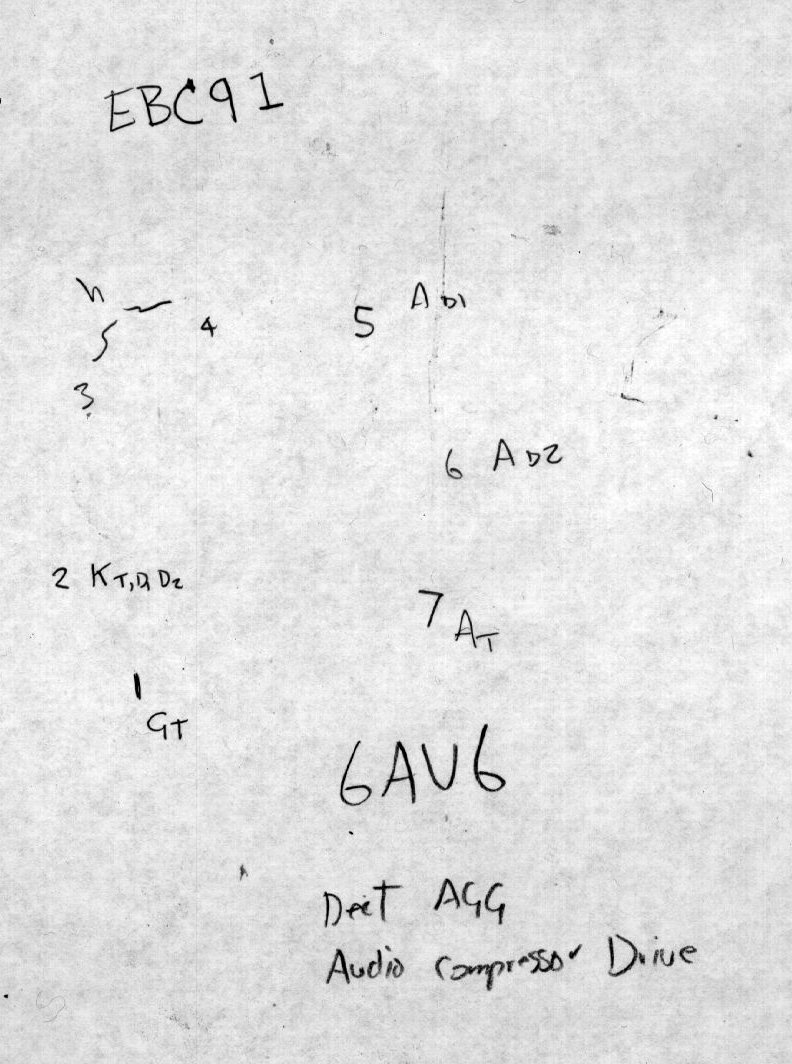

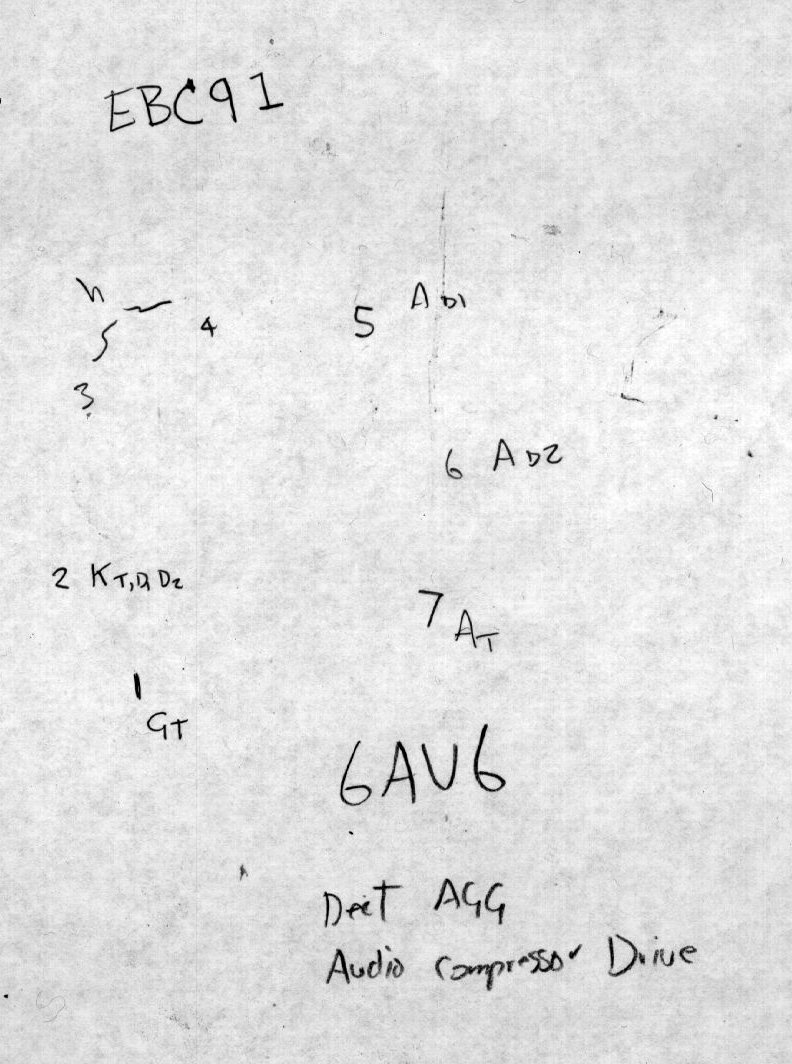

schedule of valves used in the A618 and base diagrams

detector and noise limiter and under chassis tagboad RHS

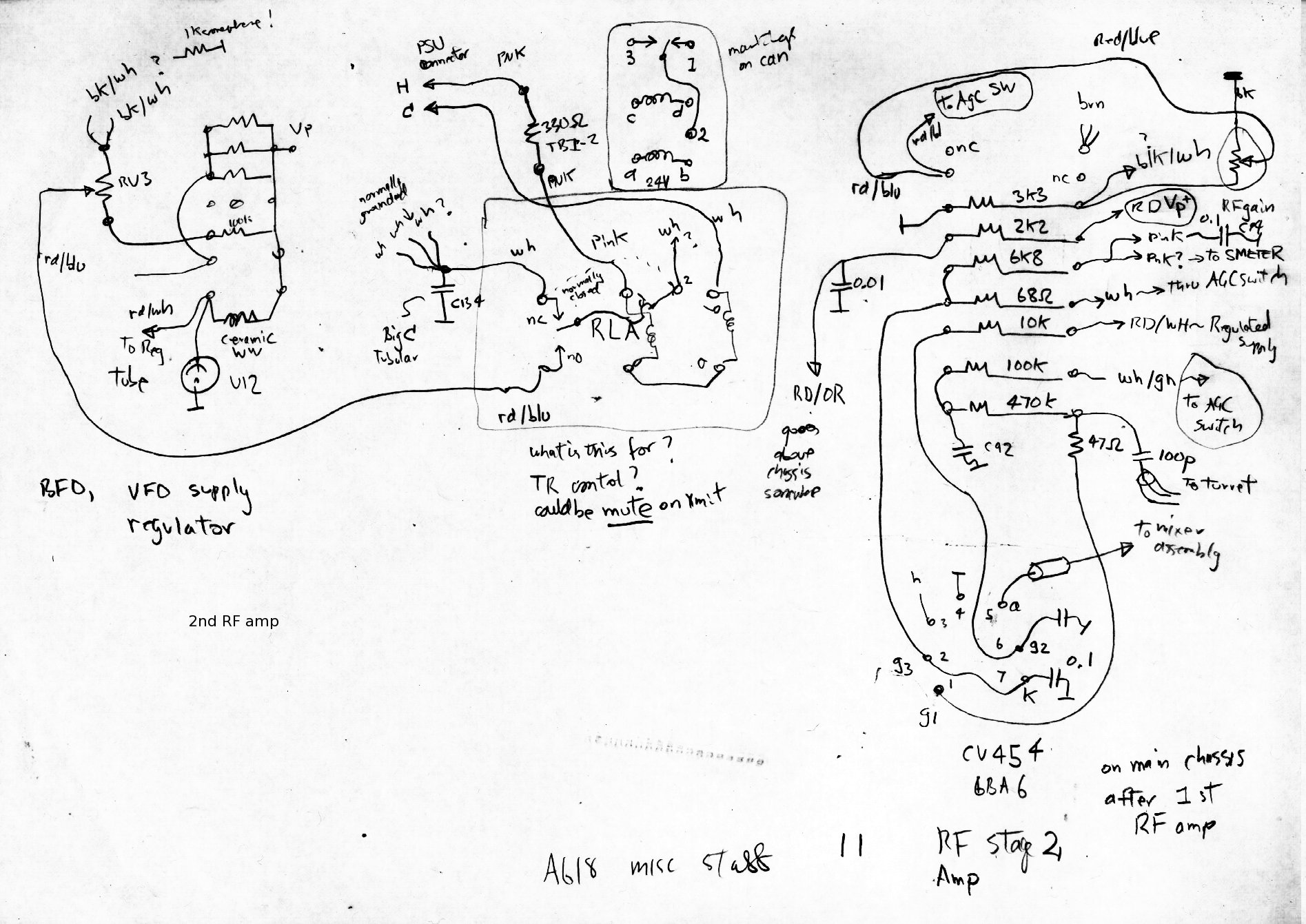

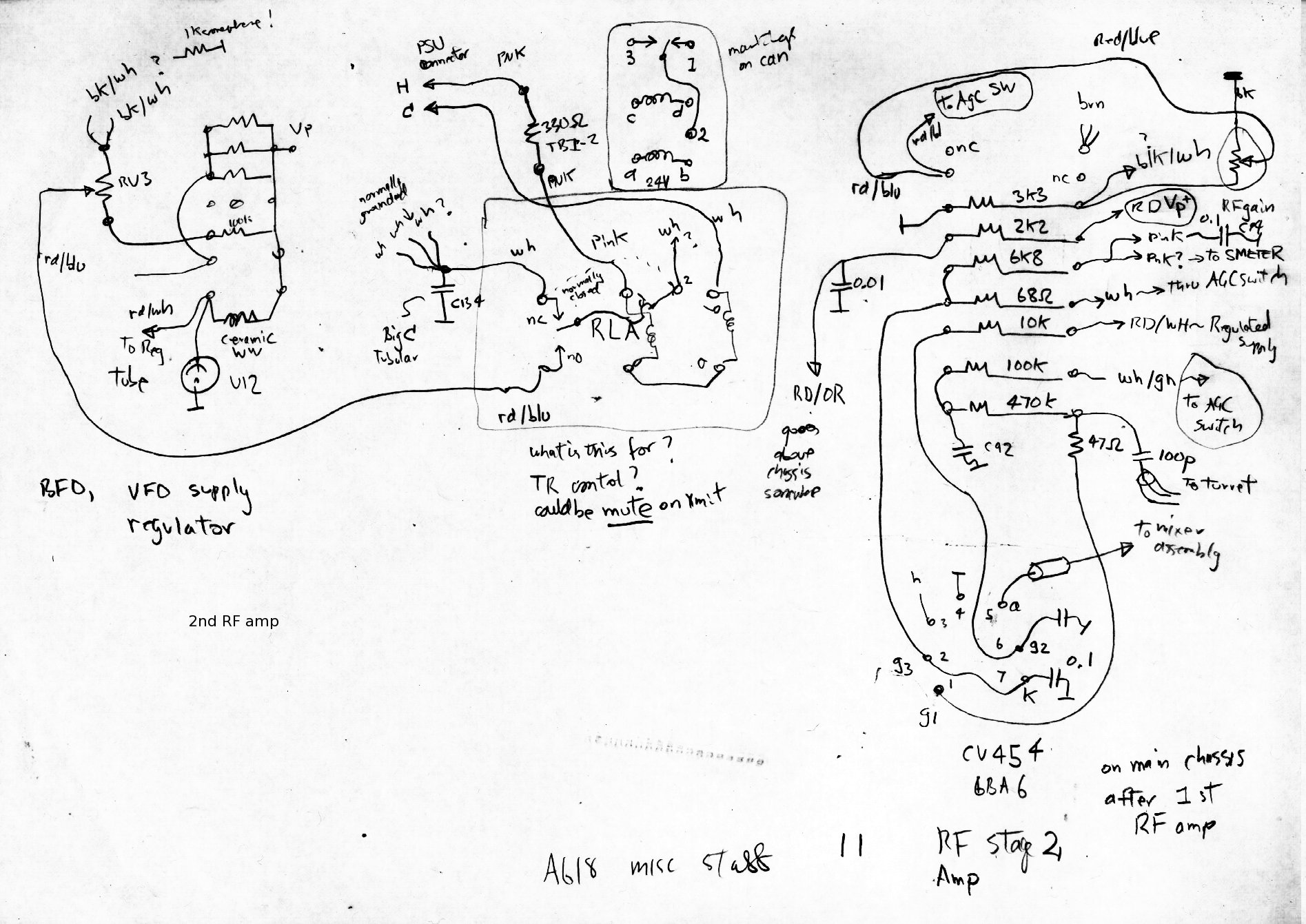

2nd RF amp, vfo regulator, mute relay

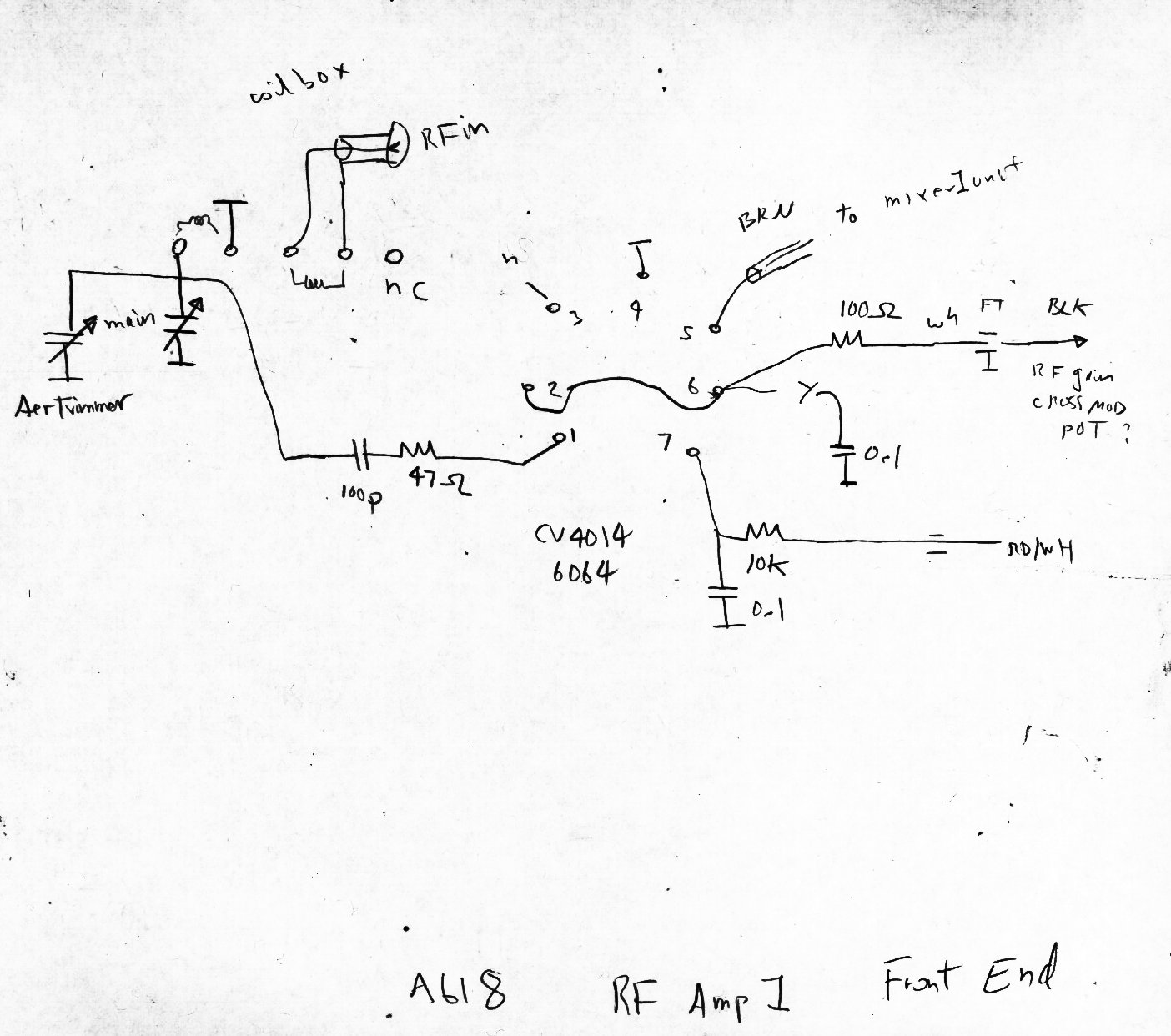

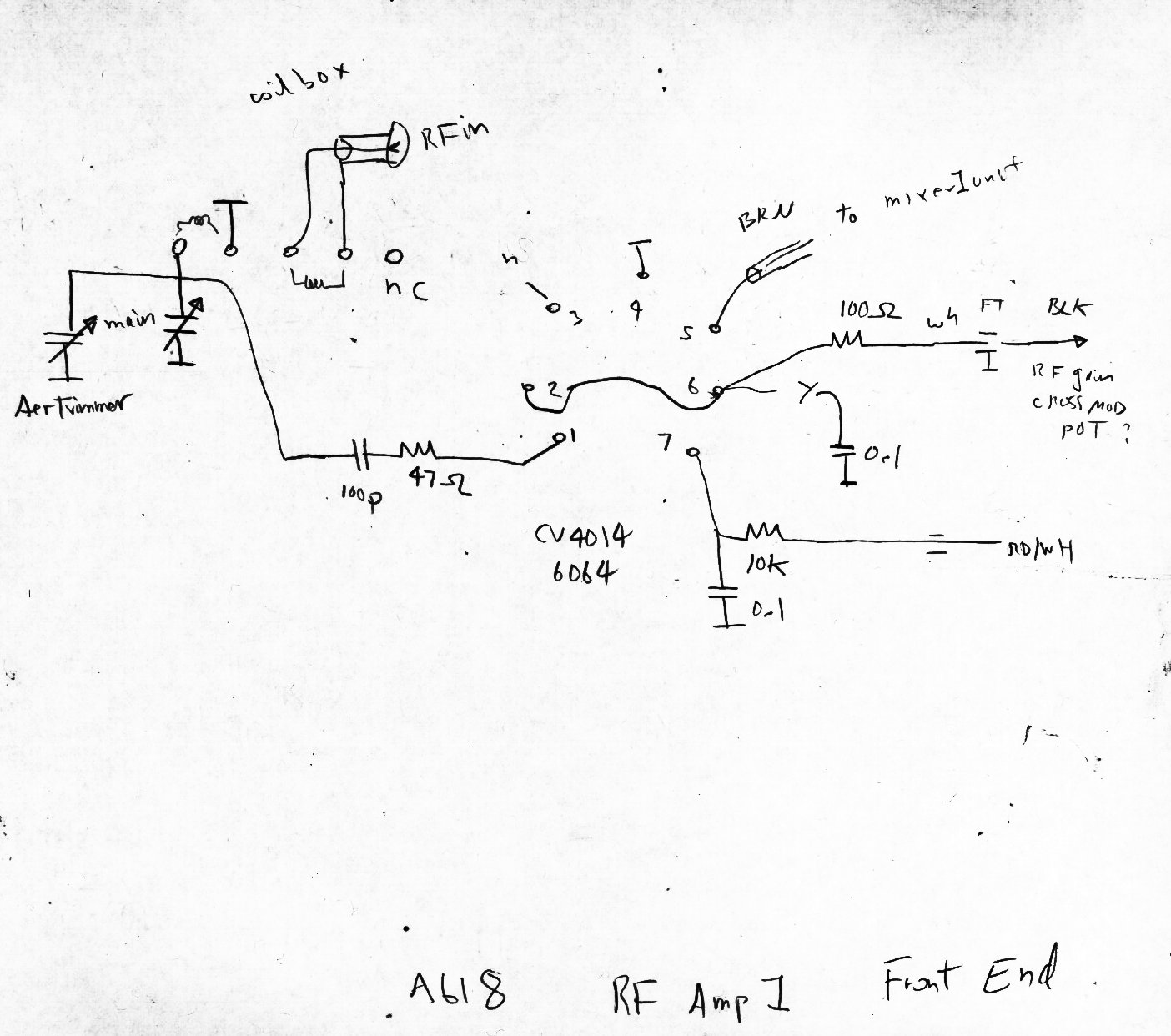

first rf amp

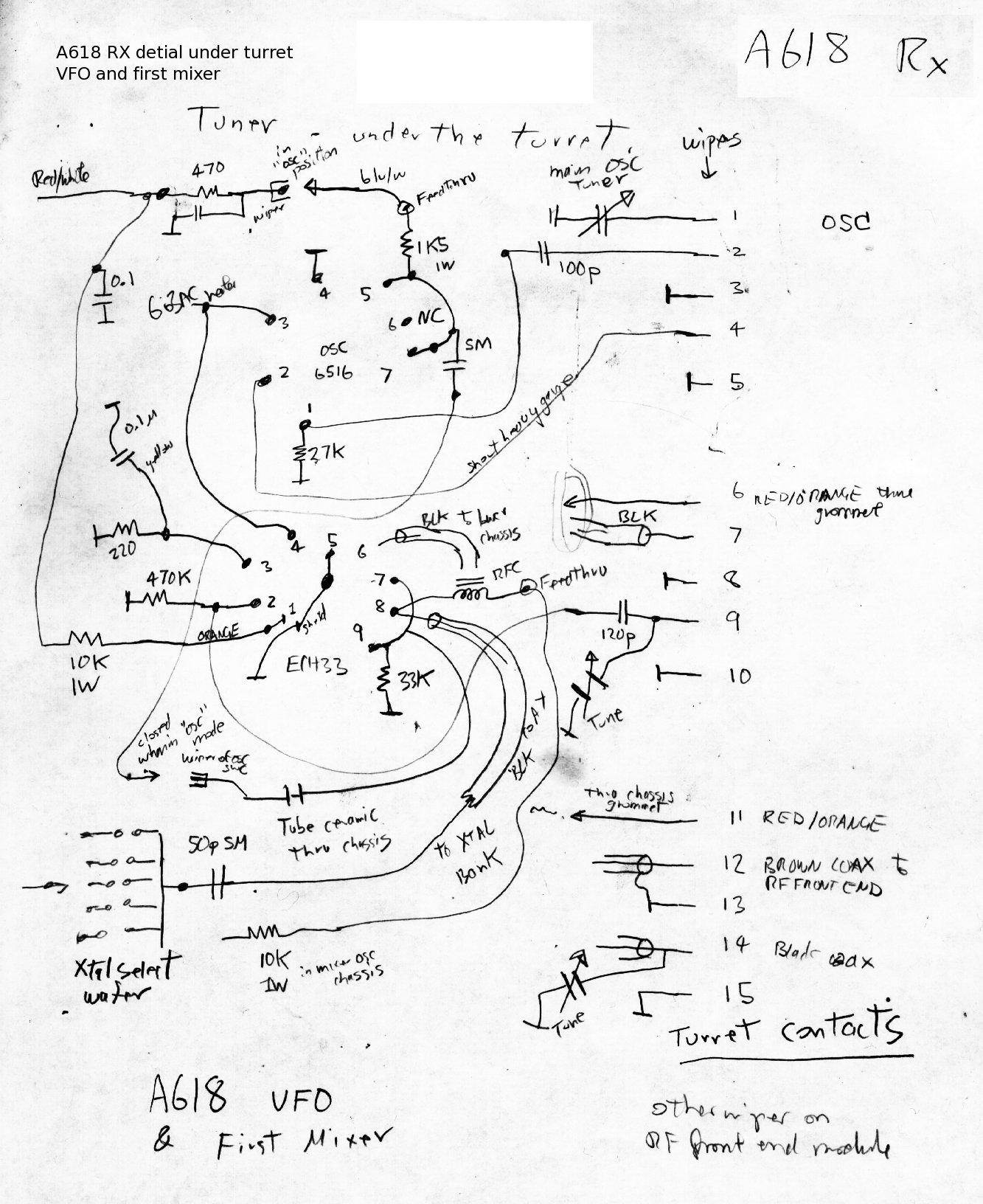

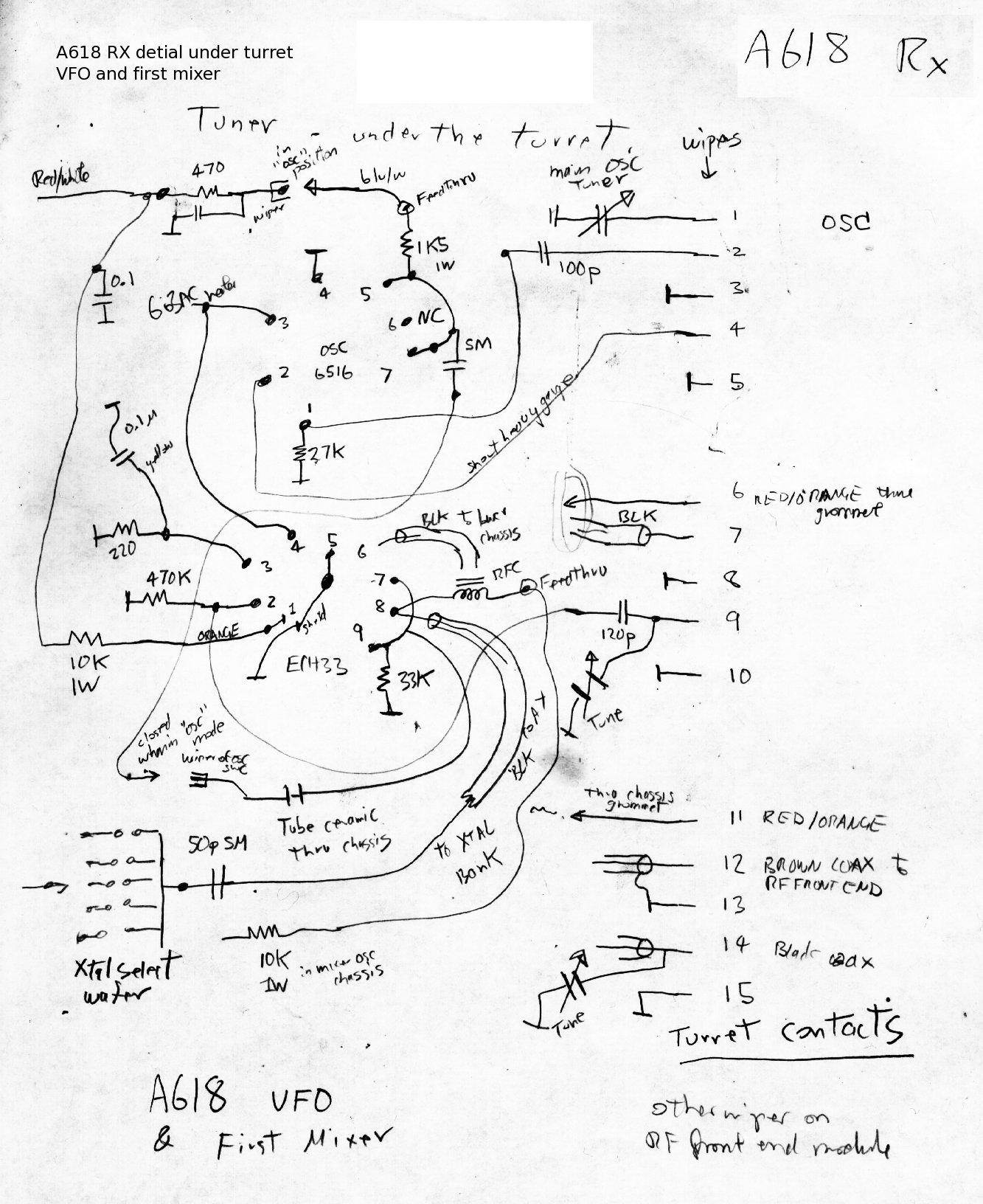

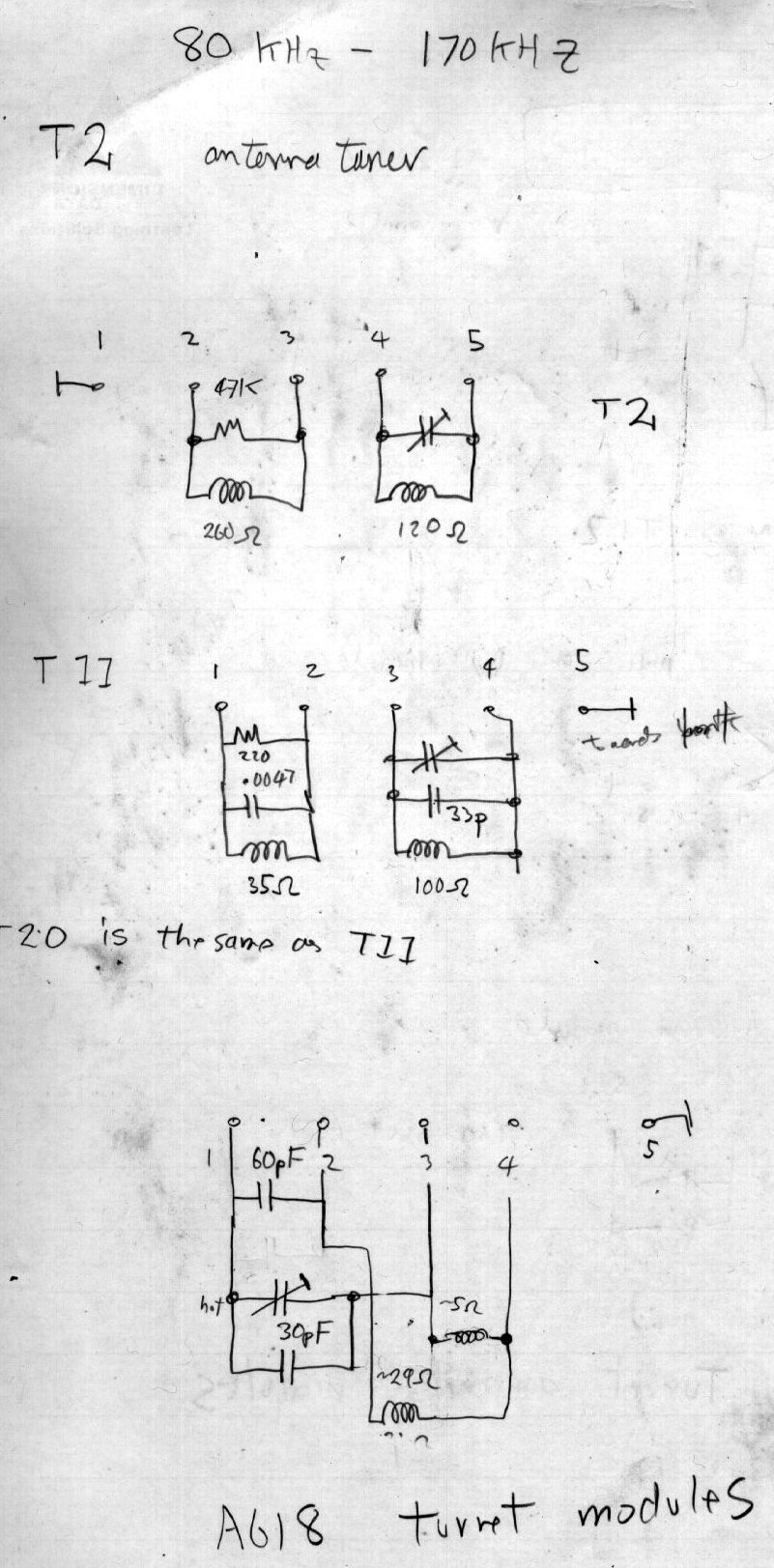

turret contacts, first mixer vfo

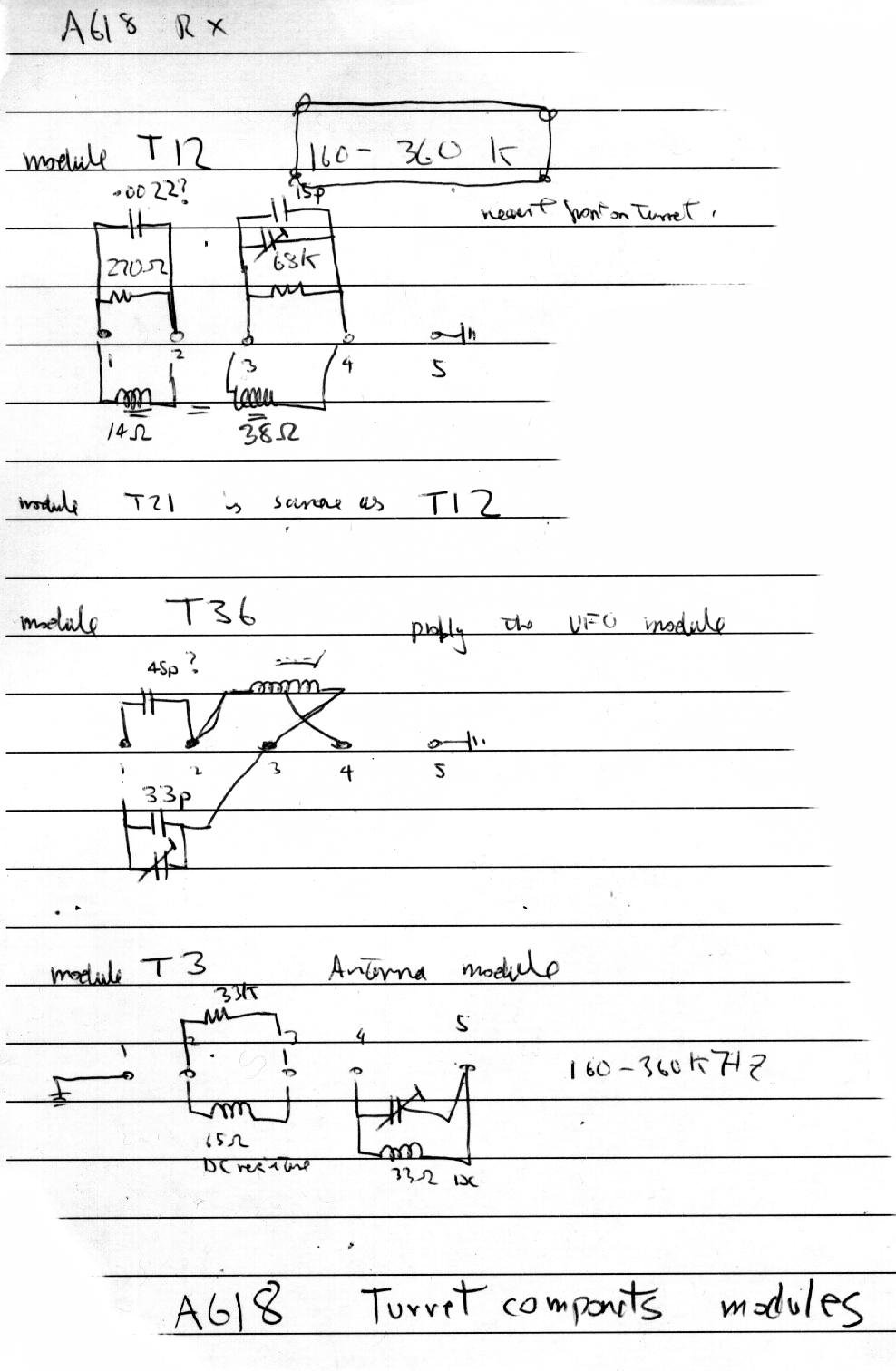

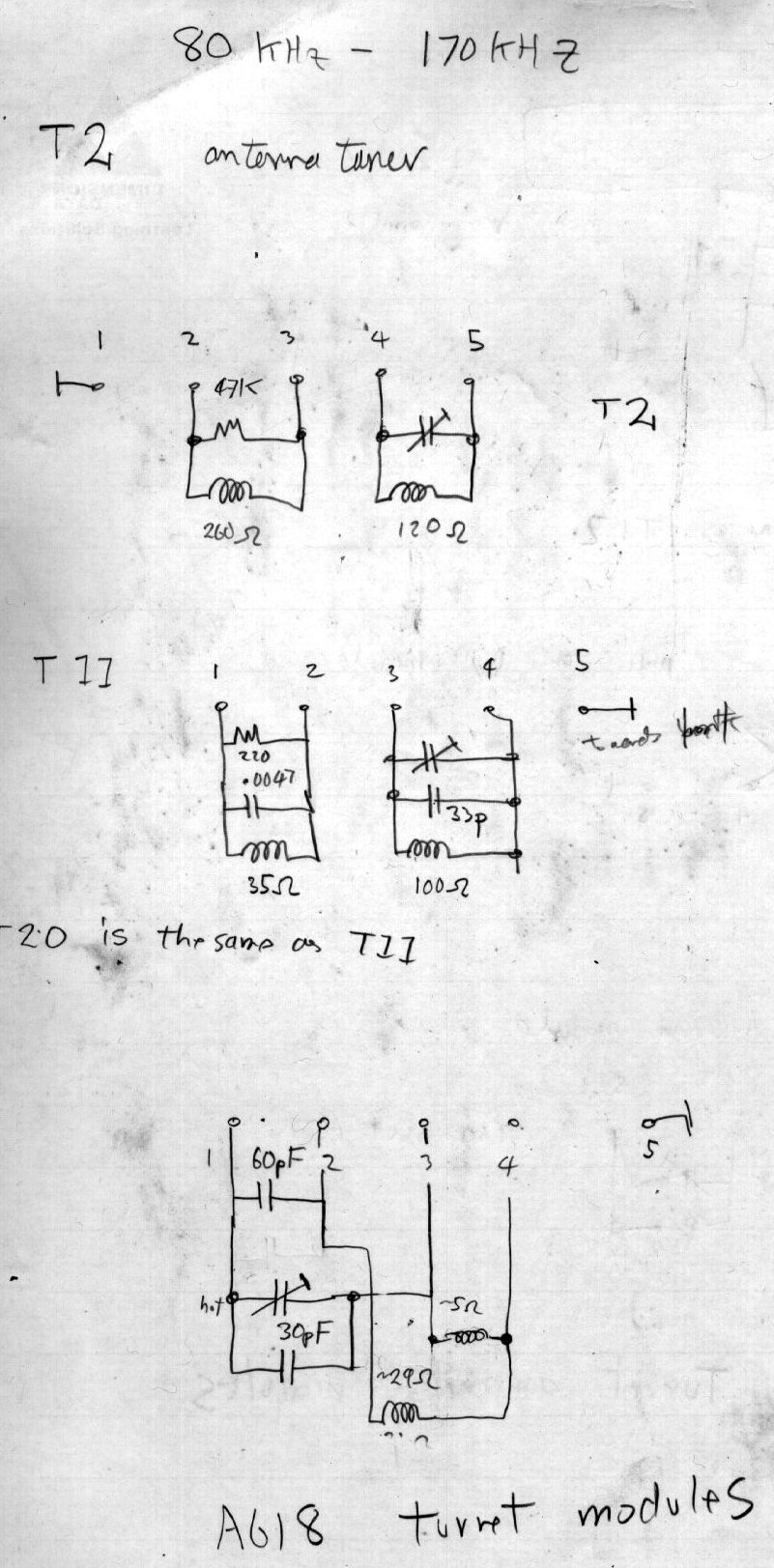

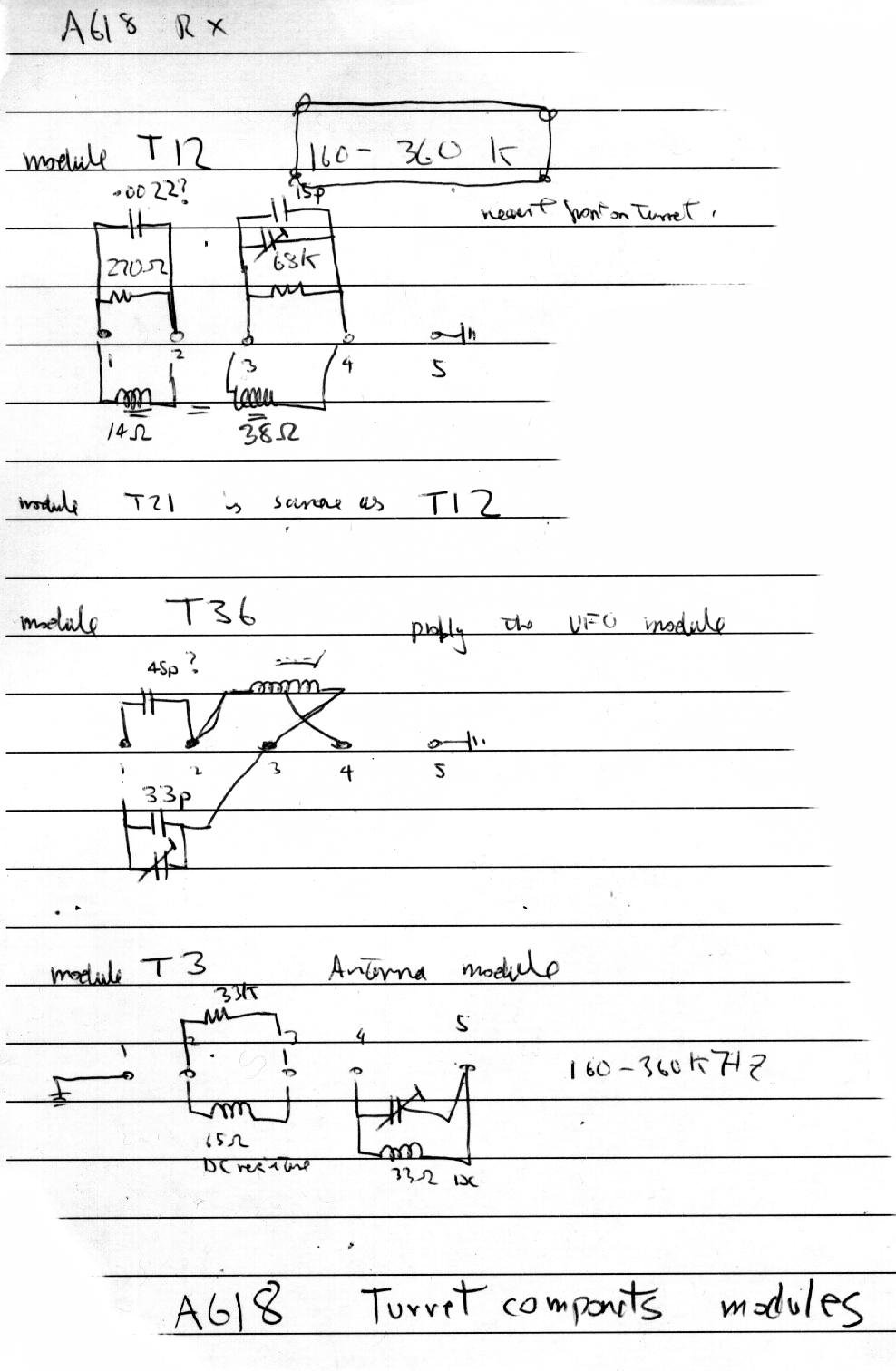

turret biscuits example

post detector af amplifier and audio

compressor.This contains my hamification. I could not find a

replacement 6AV6 triode diode so I have rewired it to use a 6AM6

triode connected as the audio agc driver and a silicon diode as audio

agc detector. This has worked well. I choose the 6AM6 because I have

many and it required the least amount of socket rewiring in a hard to

get to location.

My unit is powered from a high voltage

dc supply. It wants about 250 volts DC, 6.3VAC filament supply and a

negtive DC voltage source to supply negative bias for the agc system. I

have found that negative 12 volts is sufficient but I believe

that it officially should be negative 40 volts to get the full agc

range. The power connector has many more conductors than I have

yet mapped. The remote mute relay is controlled through the power

harness and a few other things that I havent got around to

understanding yet. They dont impact on simple normal operations.

I have owned this unit, serial number 0006, for 20 years now. It has

given little trouble over this time however in the last couple of years

there has been rapid deterioration. The unit is constructed with

one watt carbon composition resistors and nearly all resistors greater

than 10Kohms that are disipating any significant power have had to be

replaced as most have doubled or tripled their nominal resistance.

The biggest surprise was finding that audio interstage coupling

capacitors used were silver micro 0.01uF. Silver micas should

have NO leakage...right....nope your wrong. After 50 years these

devices have at least a mego-ohm leakage, some had 100K worth of

leakage. This completely deranges grid bias of suceeding stages.

Replacing these , and, all paper caps with polyesters restored

the audio compressor to life and the audio once again sounded clean.

Keep the turret contacts polished ,

dont use abrasives, bond paper is

sufficiently abrasive to get and nice shiny metal surface on the turret

bump contacts (silver metal!) . The original mil spec

valves with the CV number should still be serviceable....after fifty

years! mine are! Will YOU be serviceable in 50 years ? The

only valve that may cause some greif is the converter valves, CV2128

also known by the commercial equivalent of ECH81. They are very rare,

some may still exist in some hams bottle bank. The others have

common equivalents like 6BA6 et al. I could not find a 6AV6 to

fix the compressor so I have used silicon diodes and a 6AM6 pentode

wired up as a triode as a fucntional alternative. I think that when the

time comes to replace an ECH81 I will replace it with a TV

pentode/triode 9 pin valve. It should even have lower noise than the

ECH81 pentagrid.

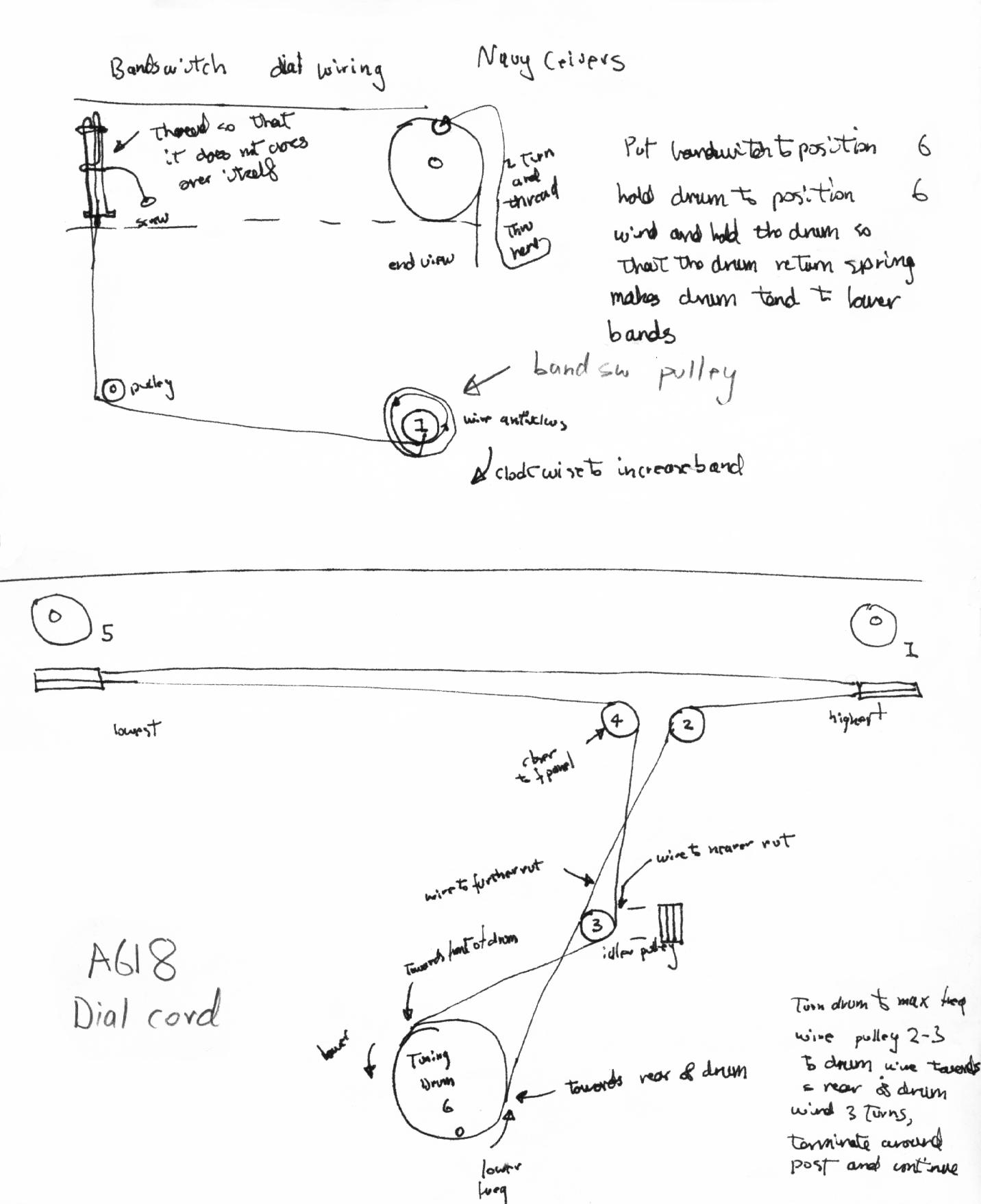

The dial cord was orginally steel standed fine piano wire, I have

restrung this several times with heavy nylon fishing line. Its a

complete pain to restring but nylon will last 7 years even in the hot

interior.

Still to do:

First mixer and first if bandswitching. This is hard due to innaccesiblity in the chassis

2nd if bandwidth selection.

easier said than done. This complex wafer switch taxes my tiny mind too

hard. It works and I hope it stays working!

Fix band 3, for some reason it

has become deaf. No good for NDB dxing. Suspect a silver mica has gone

bad, however these bakelite units were not marked in indelible ink, the

markings have evaporated.

Hamifications to think about.

The radio does not have a product detector and BFO energy leaks

into the AGC. This makes SSB reception rather trying. The radios

performance on its highest band could be better, perhaps a

shock..horror solid state front end, mosfet, to replace the first

RF amp.

And the existential question? Do

I "restore" the radio hence no hamifications, or do I bend the orginal

design to my will and improve on some notable design deficiencies

especially the lack of product detector?