"Contrary to the prior art teachings of uniform adsorbent bed temperature during pressure swing air separation, it has been unexpectedly discovered that these thermally isolated beds experience a sharply depressed temperature zone in the adsorption bed inlet end..." (Collins,J., Air Separation by Adsorption, US Patent 3,973,931, Aug. 1976)

The formation of a temperature "cold spot" in industrial O2PSa and O2VSA plants (at times as much as -70°F) has been a source of mystery and confusion in both academic and industrial communities. As reported by Collins in 1976, the cold spot significantly decreased plant performance and in many cases shut the plant down. It is reasonable to ask why O2PSA lab experiments did not report this feature - the reason is that lab units, no matter how well insulated, are not adiabatic to the extent of large diameter industrial beds. Small heat leaks significantly affect the extent of the "cold spot". The reasons for the formation of the cold spot and its dependence on design and operating conditions was the basis for this research project and is described below.

The O2VSA process is a good example of a bulk-gas adsorptive separation. Since the adsorbents used for O2VSA adsorb the nitrogen (the bulk component in air) and not the oxygen, and since adsorption is exothermic, there is a substantial temperature swing in the adsorption beds. This swing in temperature between adsorption and desorption can be as much as 10-15°C. Together with the temperature swing, the gas flows up and down the bed will convect some of this energy through the bed. Since multiple layered beds are usually employed (a guard bed is used to remove water and CO2) in O2VSA, and since the adsorbents have different adsorptive capacities and properties, it is common for unusual temperature profiles to establish themselves within the adsorption beds.

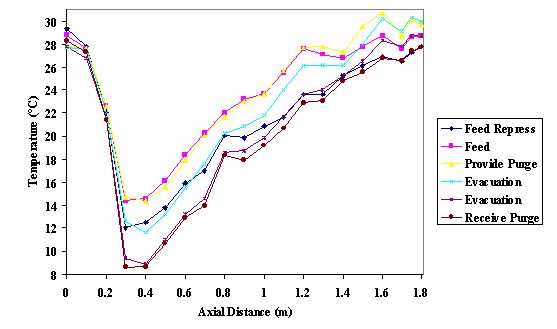

In this project (completed in 1999), we investigated the mechanisms behind the formation of temperature profiles in multi-layered VSA beds both experimentally and theoretically. The pilot scale O2VSA unit was used to measure the thermal profiles in the bed and this data together with detailed numerical simulation to validate simple hypothesis as described in mechanistic models. The figure below shows the temperature profile in a 2-layer bed at the end of each step in a cycle at cyclic steady state

The prelayer occupies the first 0.3m of the bed and consists of inert alumina. The main layer occupies the remaining portion of the bed and is high capacity LiX zeolite. Since the prelayer is inert, the temperature swing in the prelayer is very small, as seen in the figure. In the main bed, the temperature swing is larger (5-10°C) relfecting the adsorption and desorption occurring during the cycle. A pronounced "cold spot" is seen at the interface between the layers.

In essence, the prelayer acts as a regenerative heat exchanger, cooled by the desorption gas as it flows countercurrently over the prelayer and heated by the incoming feed gas during the feed step. A balance is achieved when cooling by the desorbed gas exactly matches heating by the feed gas as dictated by an energy balance. This "cold spot" does not occur in single layered beds since no "regenerative heat exchanger" is present. It is important to note, however, that if the air to a single layered bed is not dried, it will create a de facto prelayer since the moisture and CO2 will contaminate the bottom few cm of the bed greatly reducing nitrogen adsorptive capacity. A small prelayer is then inadvertently created again giving rise to a "cold spot". Much more detail on the formation of the cold spot and how to exploit it to our advantage in O2VSA design can be found in the thesis of Simon Wilson and associated publications. For more information on this project, contact Paul Webley.