the welder-o-doom

an arc welder built completely from assorted junk that actually works and has produced genuine artifacts.

by Ralph Klimek Copyleft 2007 based on work done sometime around 1992

copyleft. Copying is permitted but not recommended

The welder-o-doom

was created when some twenty years ago my friend Dave Stuart VK3ASE

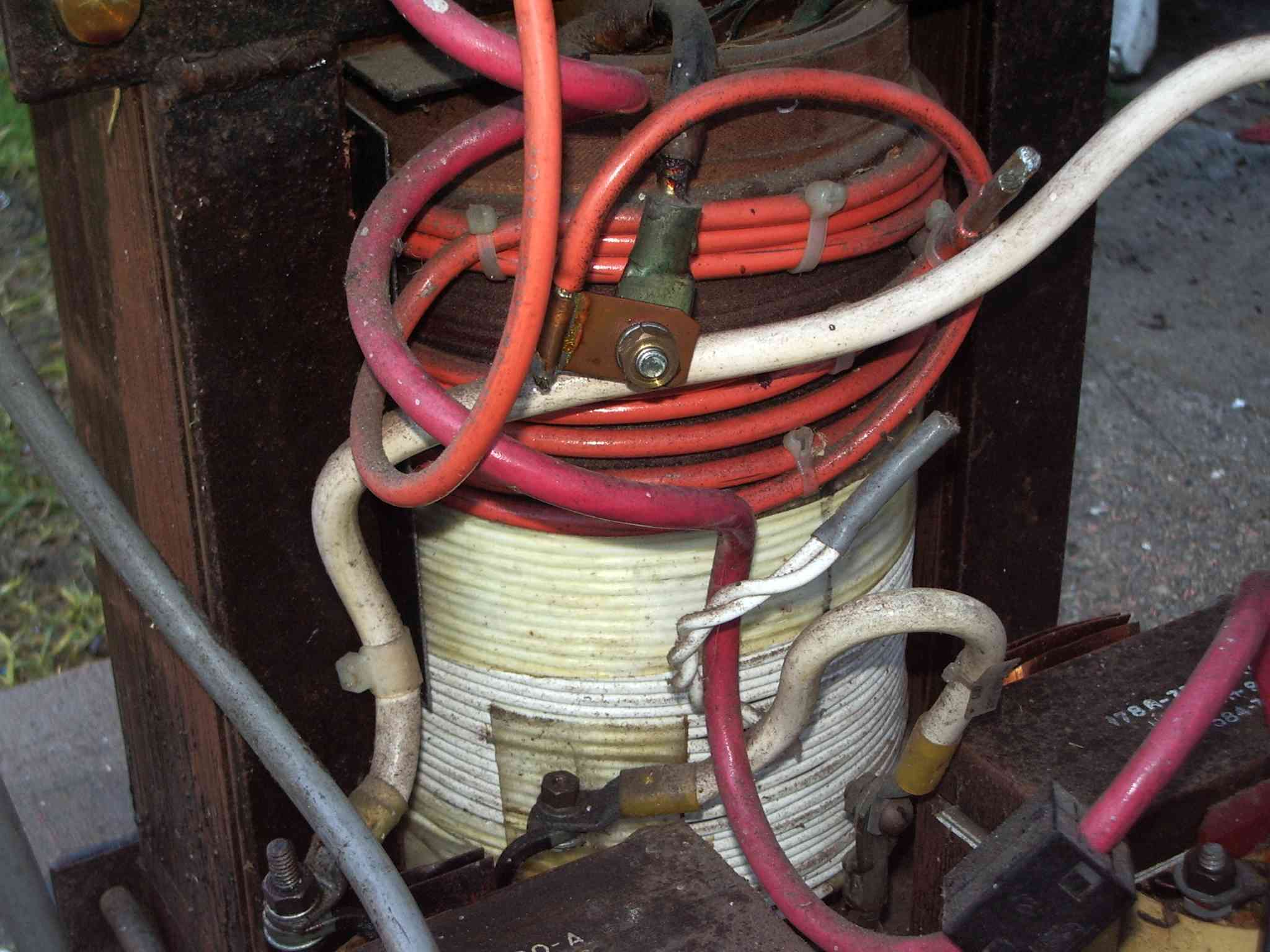

gave me the much coveted "melt 'formers". This extraordinary device was

purchased for one dollar from "the Curly wharehouse" in Wallan, which

was sharing a pasture with some moo cows. It served its initial

purpose as a telephone exchange battery rectifier transformer, then

found its second life in melting things and testing consumer durables

to destruction. Having tired of this, it found its third life in

my garage waiting for some time and inspiration. It then grew up and

got a job!

Inspiration finally arrived when my

first child appeared and we needed a new front gate to keep our toddler

from testing her luck with the traffic . I looked carefully at

this monsterous transfomer and thought that it would make the heart of

a practical welder. Its secondary voltage was 80 volts which is

just a bit too high, 50 volts is the ideal consumeable electrode arc

welder open circuit voltage. There was no doubt about the secondary, it

could source about 60 to 100 amps continuosly. To get the secondary

voltage down I wound extra turns on both the primary and secondary to

oppose the voltage and this gave me 55 volts which is ideal. I

did not want to disassemble the frame and core and unwind the primary.

The primary winding was wound over the secondary and this precluded

simply removing secondary turns to get the voltage down. Besides that

the secondary was wound with material resembling copper bar stock and

unwinding this would require more physical strength than I possess.

A welder must run from a constant

current source and for a AC welder this is done with a moveable core

inductor. I had no such thing, but I did have a couple of extraordinary

heavy DC iron core chokes from an old mainframe power supply. I

had to experiment a bit with the air gap to get the right inductance,

but the final result was a functional welding choke.

An electrode holder was constructed

from brass and aluminium 3/4inch rod and insulated with PVC pipe. After

a couple of interations with an electrode, I finally got the choke

right. I then went out a bought a proper welders mask, my eyes

had got very sore watching the arc, just for a few minutes whilst

testing to see even if my concept would work. The heavy duty

cables were all recovered from a scrapped mainframe computer DC power

supply lines. 200A cable is hard to get. I notice that it is now

possible to get 4 gauge cable in handyman lengths sold as 12volt garden

light cable. It also make a cheap substitute for loudspeaker monster

cable.

In practice with the the fixed choke I can use 2.5mm and 2.0mm

electrodes. There is not quite enough current to light up a 3.0mm

electrode.

The welder has proved to be extremely usefull, I never would have bought a real one untill I had tried this.

The construction practice of mine requires me to use it when there are

no bystanders or looken-peepers because there are bare electrical

terminals at mains potential directly exposed. The device is

worthy of Baron Frankenstein's laboratory and probably should go and

stay there!

I had a dedicated 15A heavy duty

power feed installed to the garage to feed this monster. I have

found that using a spot light to illuminate the work really helps. It

stops the "welders' salute", whereby you must allways flip up the visor

to see where the elecctrode is in relation to the work. The GPO outlet

on top is where the spot light gets plugged in. There is also a

heavy duty metal oxide varistor on the primary winding to absorb the

mighty inductive surges this thing creates. The transformer

magnetizing current is about half an amp, so a power factor correction

capacitor will help just a bit.

I installed a couple of ferrite suppressor chokes in series with the

secondary current near the handle. When using it to construct the

gate I discovered that my right arm had become very hot. It had turned

bright red and wasnt feeling great. The reason was the very large RF

currents being induced by the arc were being shunted by my hand

capacitance and heating up me, (as in radio diathermy) The

suppressor chokes stopped this unpleaseant effect and permits my

neighbours to watch TV whilst I melt metal.

It took a little while to learn to make good quality welds with this

device as just about everything is text book wrong with it. The lack of

good current control is its main deficiency.

I am no longer afraid of steel as a constructional material. It used to

be hard to cut, get and angle grinder, it was hard to drill, get cobalt

tool steel drills and it used to be hard to join so get a welder! Where

I used to see a pile of junk, these days I just see raw material

waiting to be cut and welded!

I would not bother doing this thing again, these days you can get an

adequate handyman grade welder for just over $100. When I constructed

this monster an entry level welder cost about $600.

But does it work ? YES!

The transformer is mounted on heavy duty 100kg rated castors. The

transformer weighs about 100kg. Notice the bare tap terminals, they are

at mains potential. Not recommended for children under three! Fully

approved by not one single electrical authority..

anywhere!

I can select from one of two chokes. The GPO outlet on the top is

to allow me to plug in a spot light to facilitate the work.

Extra primary and secondary turns were wound on to drop the secondary voltage to 50 volts

Homemade electrode holder

Standing next to a meter stick

please dont try this at home!

mod record Wed May 27 18:58:32 EST 2009 added email sig

Mon Nov 23 18:55:25 EST 2009 added linkto drillbit article