|

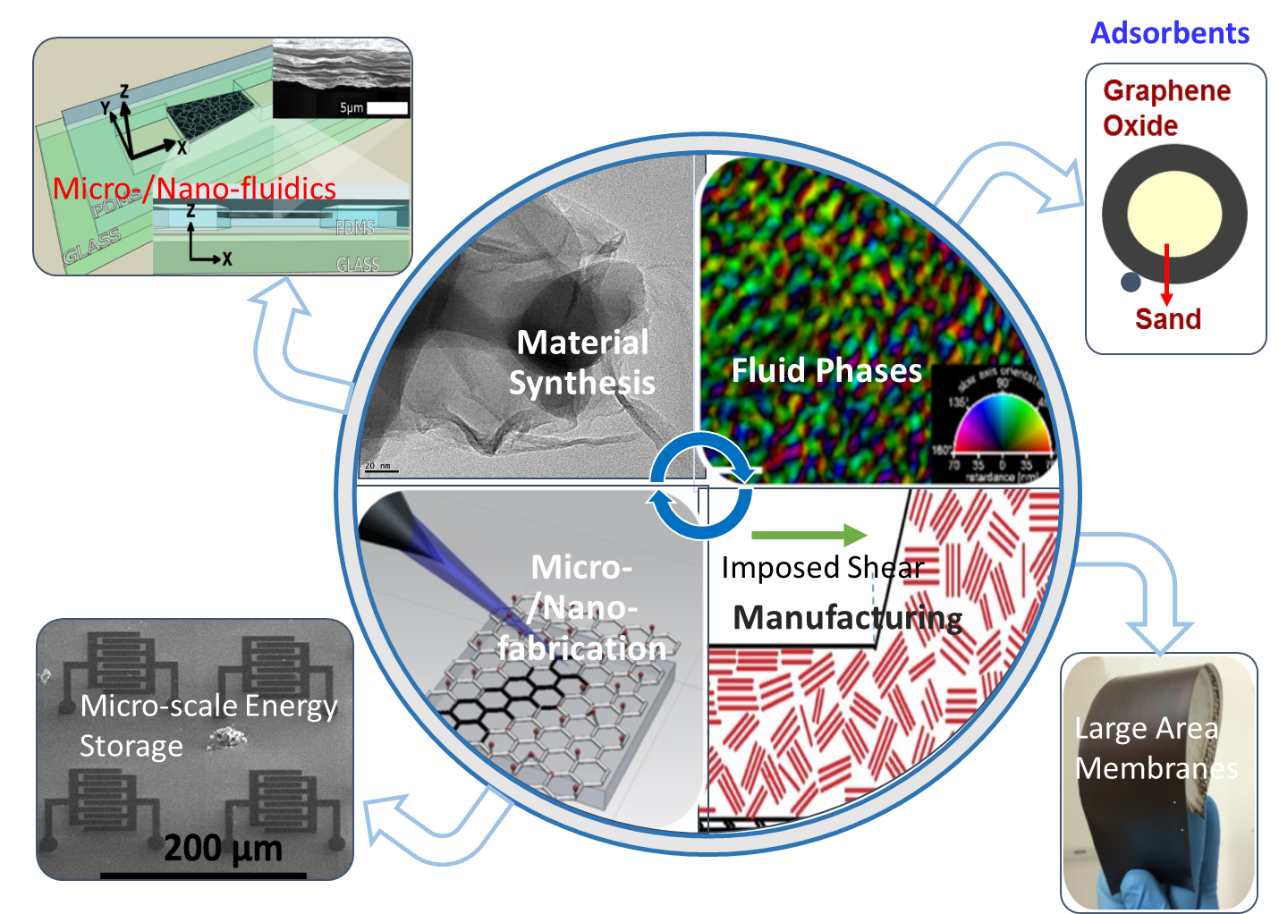

Overview of research theme

in our group where we combine the

synthesis of 2D materials such as

graphene with fundamental studies of

colloidal phases and flow behaviour

to arrive at industrially-adaptable

manufacturing and fabrication

methods in developing efficient

graphene-based platforms for clean

energy, chemical separations and

micro-/nano-fluidics.

Graphene-based energy materials and

devices program:

Most of the research activity

centers around exfoliation of

graphite in liquid phase

predominantly as a highly oxidized

and water soluble precursor –

graphene oxide (GO). Graphite is a

naturally occurring mineral deposit

which serves as a cheap source for

these advanced materials, thus

highlighting a significant value

addition to this mineral resource.

Graphene-based materials because of

their monoatomic thickness possess

massive surface area, large

electrical conductivity, mechanical

flexibility and can be processed

easily in the fluid phase. The

energy program endeavours to develop

novel energy storage materials,

architectures and devices in the

space of super-capacitors and

batteries.

Miniaturization of energy storage

devices:

Microarchitecture plays a

significant role in enhancing the

power and energy density of

super-capacitor devices. If two

electrodes can be spaced very close

to each other with micron-scale

resolution and the dimensions of

each electrode could be

miniaturized, electrode kinetics

will be dramatically enhanced and

active electrode surface area could

be much better utilized. The upshot

of miniaturization is that the

reduced dimensions not only have

very large energy and power

densities, but also can be densely

packed in a given area.

Graphene-oxide (GO), which is

essentially an insulator, can be

processed into continuous films and

conductive pathways in the GO film

can be imprinted by different

irradiation techniques such by using

laser, UV radiation and ion-beams

enabling precise pattering

methodologies [1]. A significant

aspect of the program will focus on

the chemical reduction mechanisms,

microstructure and carbon structure

evolution, and how patterning

approaches could be developed based

on these fundamentals. The second

aspect of the program will focus on

measurement of electrochemical

properties in wide ranging

electrolytes to unearth how carbon

structure, electrolytes and

microarchitecture affect energy and

power density [2]. The third aspect

of the program will focus on device

construction, integration and

proto-typing. The significance of

the program is that while the

microelectronic industry has made

rapid progress in following the

Moore’s law, is it possible that the

energy storage sector can follow

suit if we adapt micro-fabrication

strategies in energy storage

technologies?

Skills to be acquired in this

project: micro-/nano-fabrication,

electrochemistry, system design for

energy storage devices

MOF/Graphene Composites:

Metal Organic Frameworks (MOFs) are crystalline,

open-porous materials consisting of

metal ions or metal-oxo units

coordinated by electron donating

organic ligands and possess very

high surface area (~7000 m2/g)

well defined pore sizes and tailorable

structure. However, their

electrochemical charge storage

properties are poor because of their

poor electron conductivity. The

research theme will explore the

synthesis of different MOFs and

formation of intimately mixed

composites with graphene in bulk

scale quantities. This will be

followed by characterization of the

material and investigation of their

charge transport, mass transport and

electrode kinetics using a variety

of electrochemical techniques such

as cyclic voltammetry, impedance

spectroscopy, galvanostatic

polarization, and

spectro-electrochemistry. Given the

rich family of MOFs known today and

the ability to tailor their

structure during synthesis there is

potential for generation of

extensive fundamental data and

applications to be realized for high

energy and high power density

super-capacitor materials [3].

Graphene-based fluidic systems

program - from compact

micro-/nano-fluidic devices to large

area filtration membranes:

The fluidics program deals with

fundamental aspects of fluid-phase

processing of 2D materials. and

applied aspect of fluid and mass

transport through layered 2D

structures in the form of films,

granules and micro-/nano-fluidic

devices.

Graphene membrane development and

application:

GO has rich colloidal phase

behaviour because of its large

lateral dimension to thickness ratio

and exhibits phase transitions from

isotropic to nematic liquid

crystalline phases [4] depending

upon concentration of GO and pH. GO

is also a very flexible molecule

with a small persistence length and

non-conservatively can be considered

as a polymeric fluid. Using

techniques such as

orientation-mapped polarized light

microscopy and rheology we determine

how these materials can be processed

into macroscopic structures such as

films, droplets, granules or fibers

by industrially-relevant

manufacturing approaches [5]. Based

on fundamental understanding between

processing and property we have

developed scalable roll-to-roll

process for the manufacture of

multi-layer graphene-based membranes

[6]. Graphene based membranes have

unique combinations of chemical

inertness, fouling resistance, fast

water transport in the liquid and

vapour phase, nanoscale capillaries,

tunable molecular weight cut-off

with tremendous potential in

nanofiltration and pervaporation

that could solve separation problems

for e.g. in recovery of precious

metals and expensive chemicals in

challenging environments and

dehydration of organic-water

mixtures. Given our demonstrated

ability to manufacture these

membranes with massive scalability,

we will next focus on realizing

these applications. Additionally

through collaborations with

simulation experts we will unravel

the fundamental aspects of molecular

transport through these membranes

structures which has been the

subject of intense research in the

past few years [7].

Skills to be

acquired in this project: polarized

light microscopic imaging, rheology,

membrane fabrication, membrane

transport

Engineered Adsorbents: Emanating from our ability to process the solution-stabilized

graphene sheets is our ability to

easily form 3D structures such as

granules by coating over an existing

granular structure such as a sand

grains or an adsorbent granule. We

have previously demonstrated the

utility of these granular structures

as filtration materials in

column-based filtration [8]. Given

that the coating chemistry can be

tuned by the functional groups and

mass transport controlled by the

porosity of the assembled

structures, a wide variety of

pollutants could be targeted. Among

them sequestration of trace organics

and mercury from pollution streams

will be of immediate significance.

It is expected that significant

industrial interest can be generated

in this research program.

Skills to be acquired in this

project: Graphene chemistry,

adsorptive separation technologies

Micro-/Nano-Fluidics:

Graphene-based multilayer thin films

are exciting new materials for

fluidic systems because these films

form ensemble nano-capillaries

between each individual graphene

sheet of ~ 1nm regardless of the

size of the graphene microplates and

the size of the continuous films.

These films can be positioned

directly on a substrate at precise

locations with dimensional control

of hundreds of microns by simple

masking processes, but these films

contain assembled nanoscale

capillaries which are permselective

[9]. The abilities to precisely

place these nanocapillaries enables

us to integrate nanofluidics with

microfluidics, thus opening up a

host of possibilities in fundamental

understanding of ion-transport

behaviour such as electrosmosis,

electrophoresis and ion-current

rectification [10],

while empowering us to

effectively use these nanoscale

phenomena in chip-based separations

by interfacing with microfluidics

and surface functionalization

chemistries.

Skills to be acquired in this

project:

Microfluidics, nanofluidic transport

measurement.

References (published by our research

group along with collaborators)

[1]

D. E. Lobo, J.Fu, T.Gengenbach,

M. Majumder, "Localized

Deoxygenation and Direct Patterning

of Graphene Oxide by Focused Ion

Beams”

Langmuir,

2012,

28,

41,14815–14821

[2] D.E.Lobo,

P.Chakraborty-Banerjee, C.Easton,

M.Majumder, “Miniaturized

In-plane Electrode Systems of

Reduced Graphene Oxide with Enhanced

Energy and Ultra-high Power

Densities by Focused Ion-beam

Engineering”

Advanced Energy

Materials, (in

press)

[3] P. Chakraborty-Banerjee,

D.E.Lobo, R.Middag, W.K.Ng,

M.Majumder, “Electrochemical

Capacitance of Ni-doped MOF-5 and

reduced graphene oxide composites:

More than the sum of its parts”,

ACS Applied Materials and Interfaces, 2015,7,6,3655-64

[4] R.Tkacz,

R.Oldenbourg, S.B. Mehta, A. Verma,

M.Miansari, M.Majumder, "pH Dependent Isotropic to Nematic Phase Transitions

in Graphene Oxide Dispersions Reveal

Droplet Liquid Crystalline Phases",

Chem.Commun,

2014,50,

6668-6671

[5]

R.Tkacz, R.Oldenbourg, A.Fulcher,

M.Miansari,

M.Majumder, "Capillary-Force

Assisted Self-Assembly (CAS) of

highly Ordered and Anisotropic

Graphene-Based Thin Films",

J.Phys.Chem.C,

2014,

118 (1), 259–267

[6]

M.Majumder,

A. Akbarivakilbadi, “A method for

producing graphene and graphene

oxide membranes”, Australian

Provisional Patent, 21 Nov, 2014

[7]

M.Majumder

and B.Corry, “Anomalous Decline

of Water Transport in Covalently

Modified Carbon Nanotube Membranes”,

Chem.Commun, 2011, 47,

7683-85

[8] W.Gao,

M. Majumder, L. Alemany, T. Narayanan, M. Ibarra, B.K. Pradhan,

P.M. Ajayan, “Engineered Graphite

Oxide Materials for Application in

Water Purification”

ACS Applied Materials and Interfaces,

2011,3,

6,1821–1826

[9]

M.Miansari, J.R.Friend. P.Chakraborty-Banerjee,

M.Majumder, L.Y.Yeo, "Graphene-based planar

nanofluidic rectifier",

J. Phys. Chem. C,

2014,

118

(38), 21856–21865

[10]

S.Martin,

A.Neild,

M.Majumder,"Graphene-based

ion rectifier using macroscale

geometric asymmetry",

APL Mat. 2,

092803, 2014 - Special Topic in 2D

Materials.

|