|  |  |

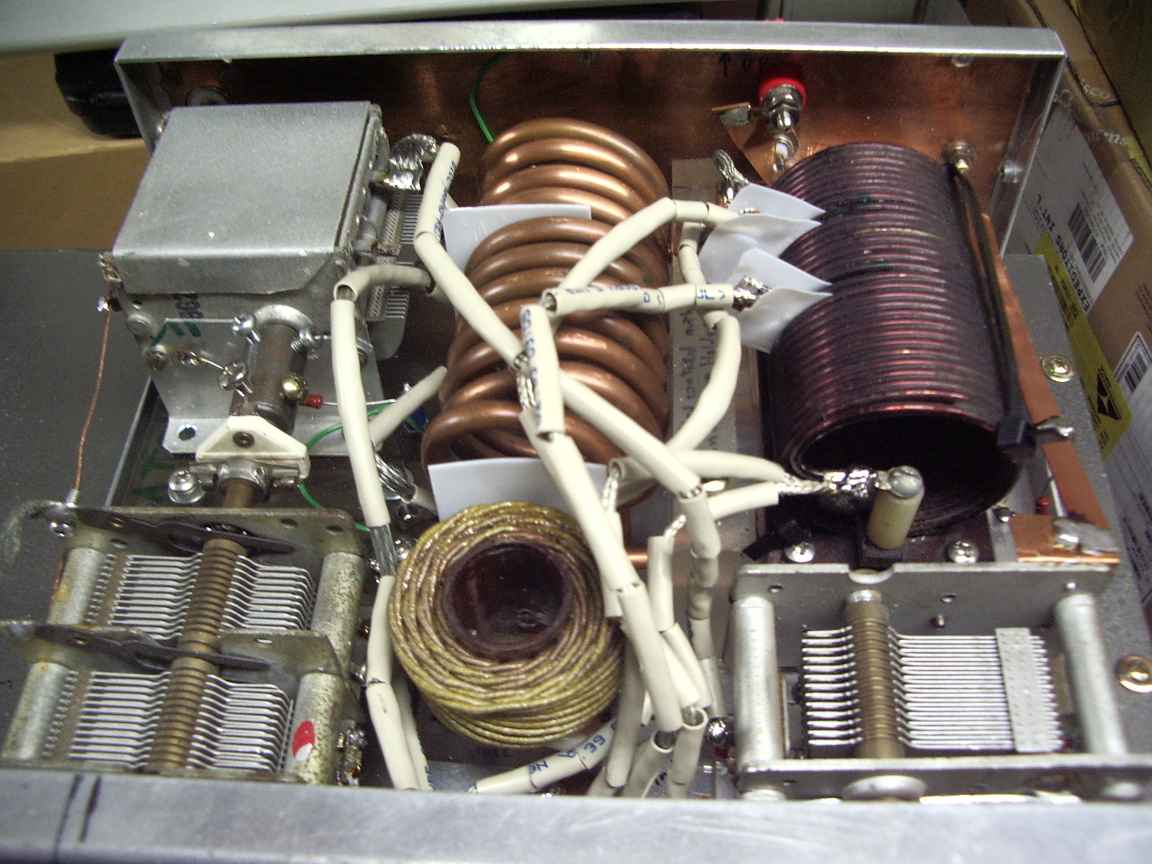

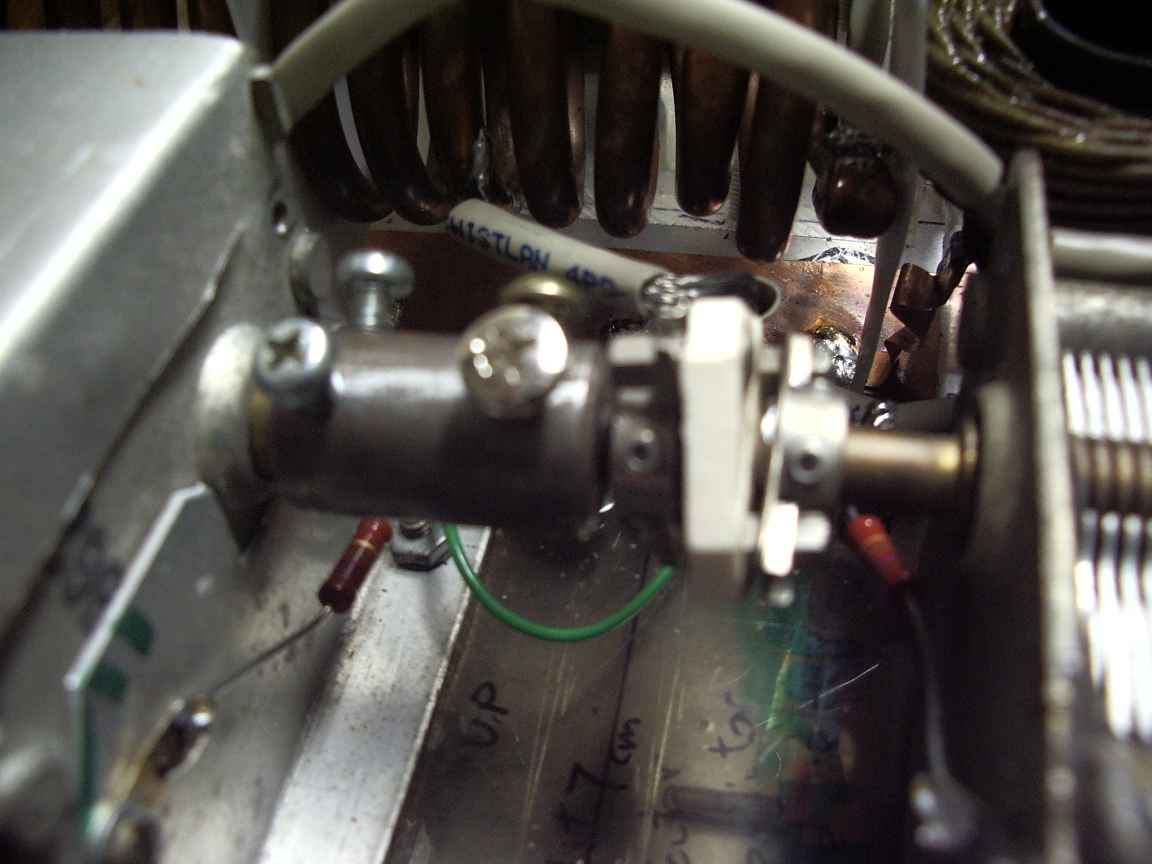

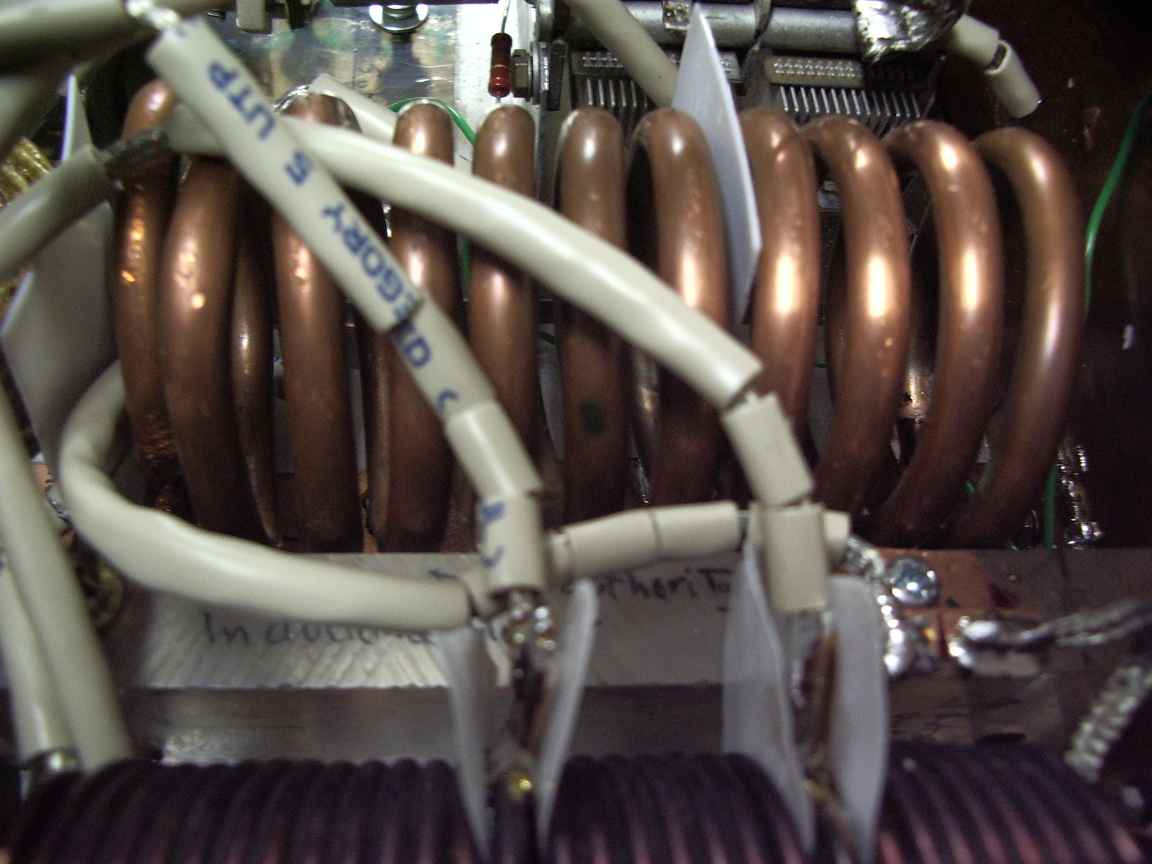

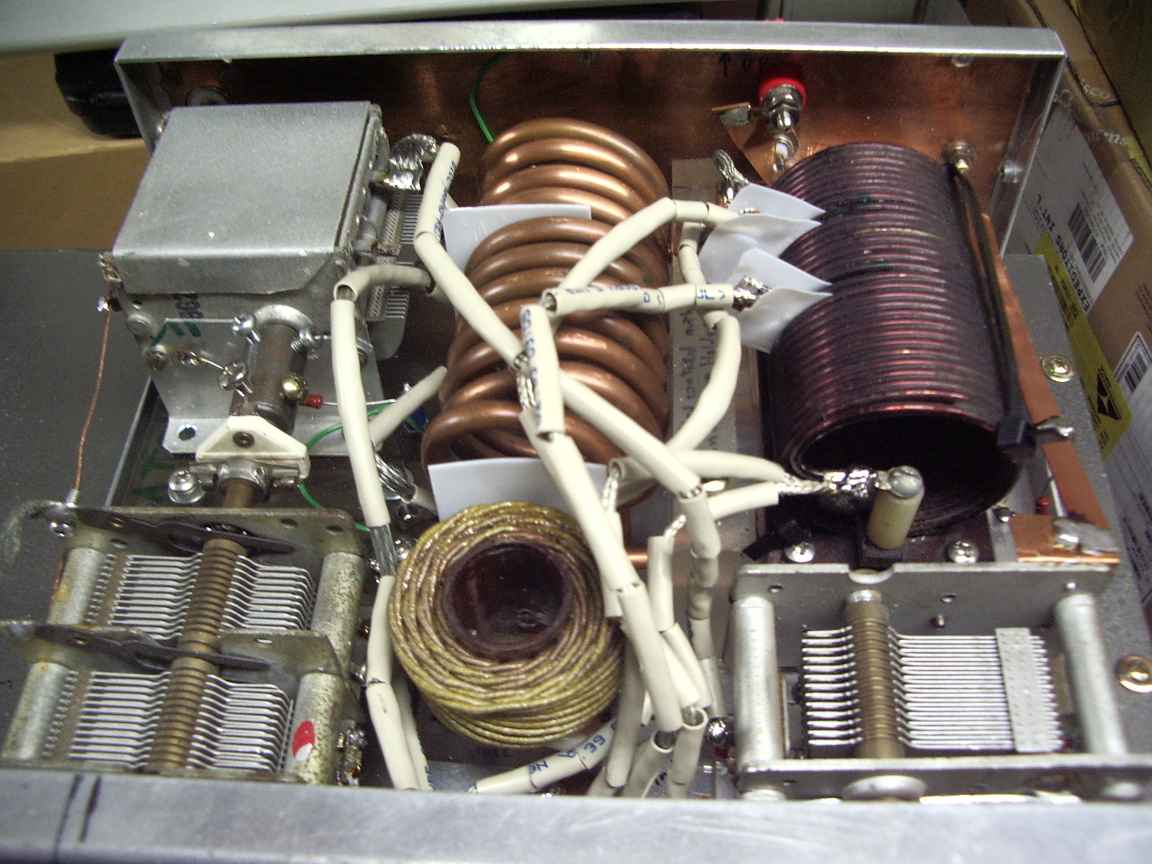

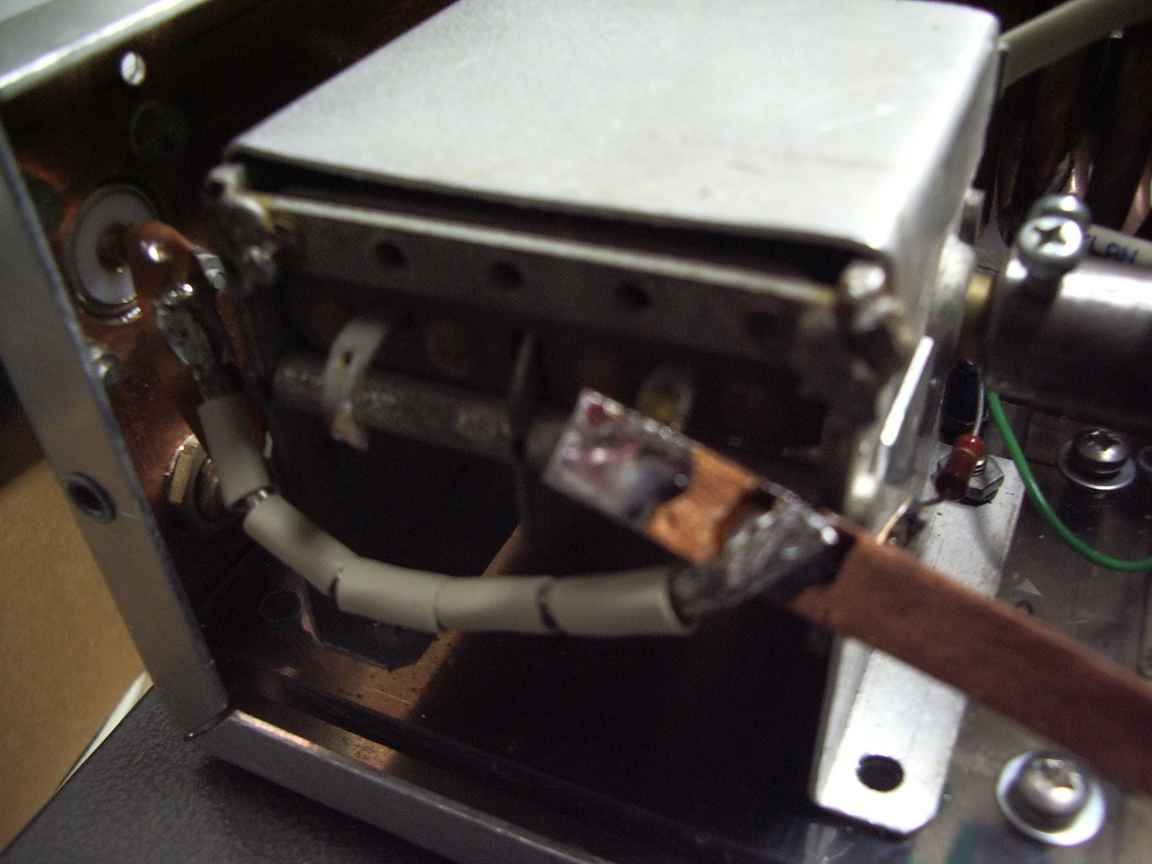

| the completed transmatch | taps on the medium inductor. a piece of teflon is removing a self inflicted shorted turn. | top view, copper backplane for positive RF grounding |

|  |  |

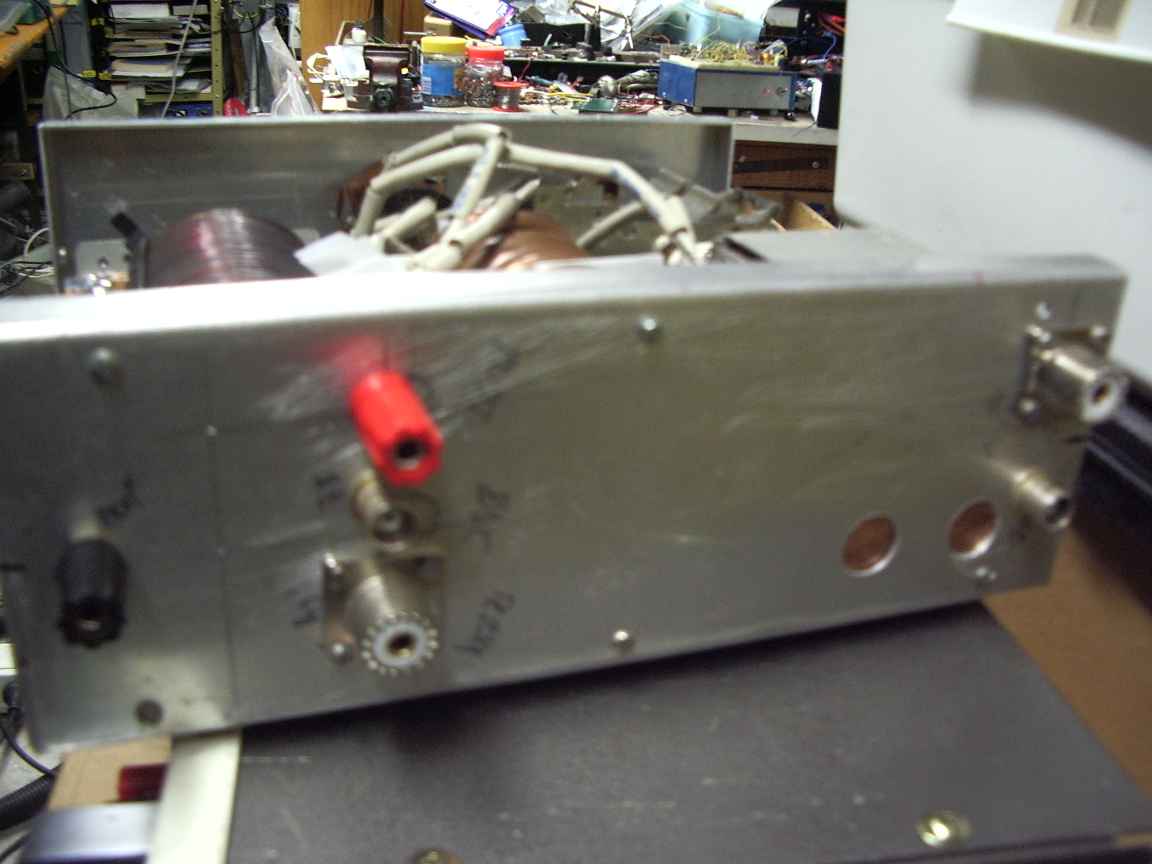

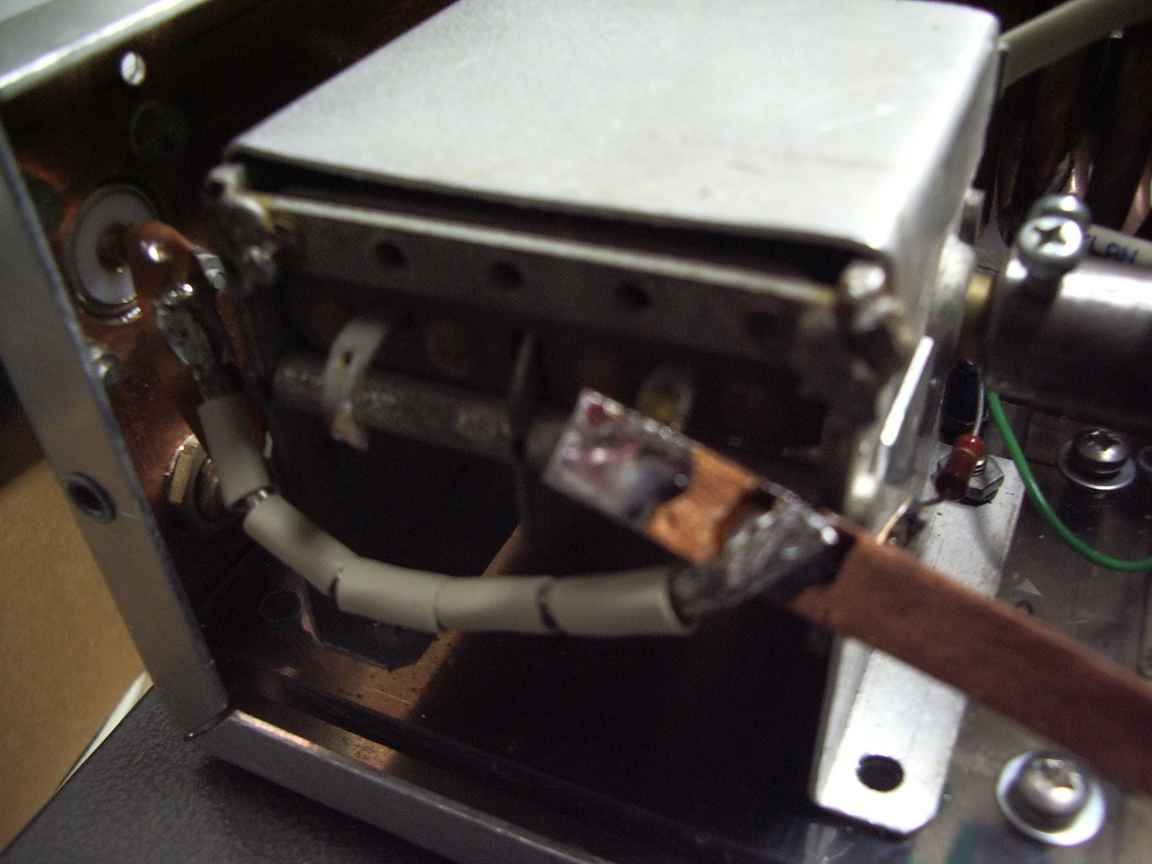

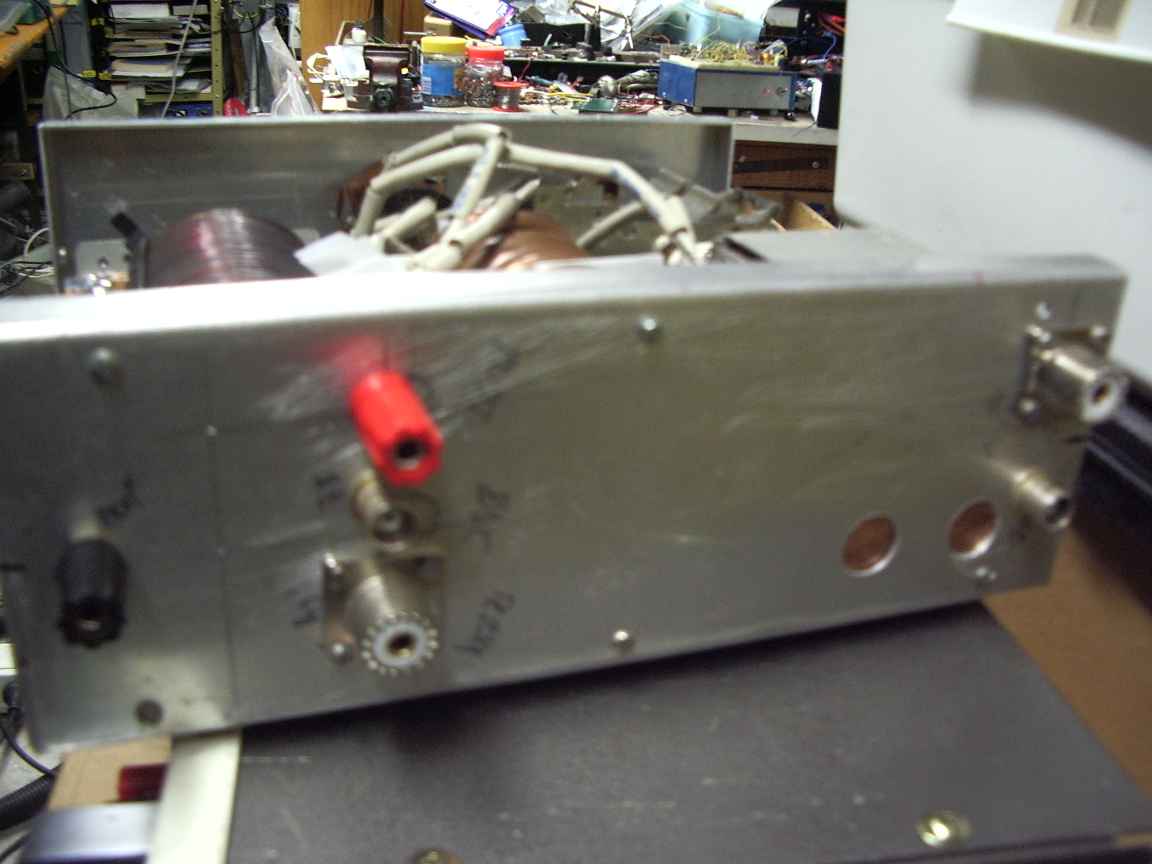

| top cover with copper flashing shield near the inductors | differential capacitor at 2/3rds mesh | there was space so I put in both PL259 and BNC and terminal posts |

|  |  |

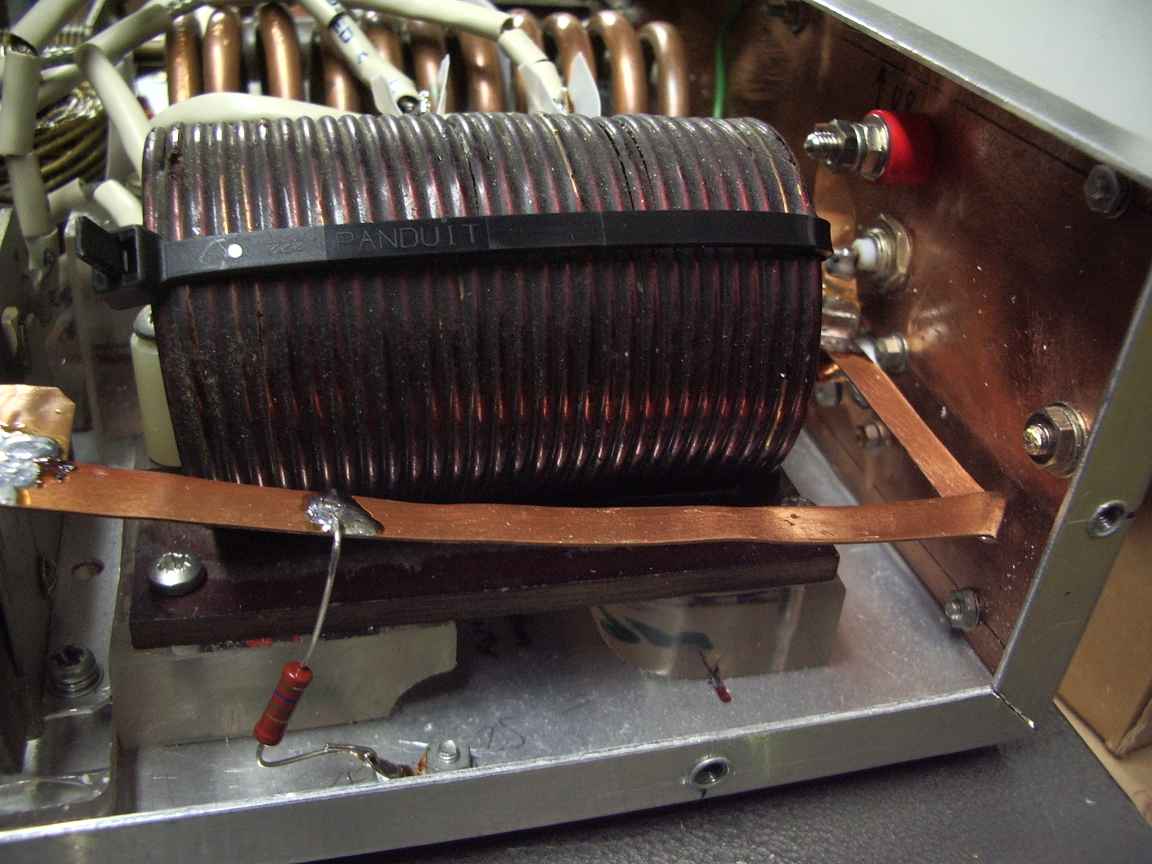

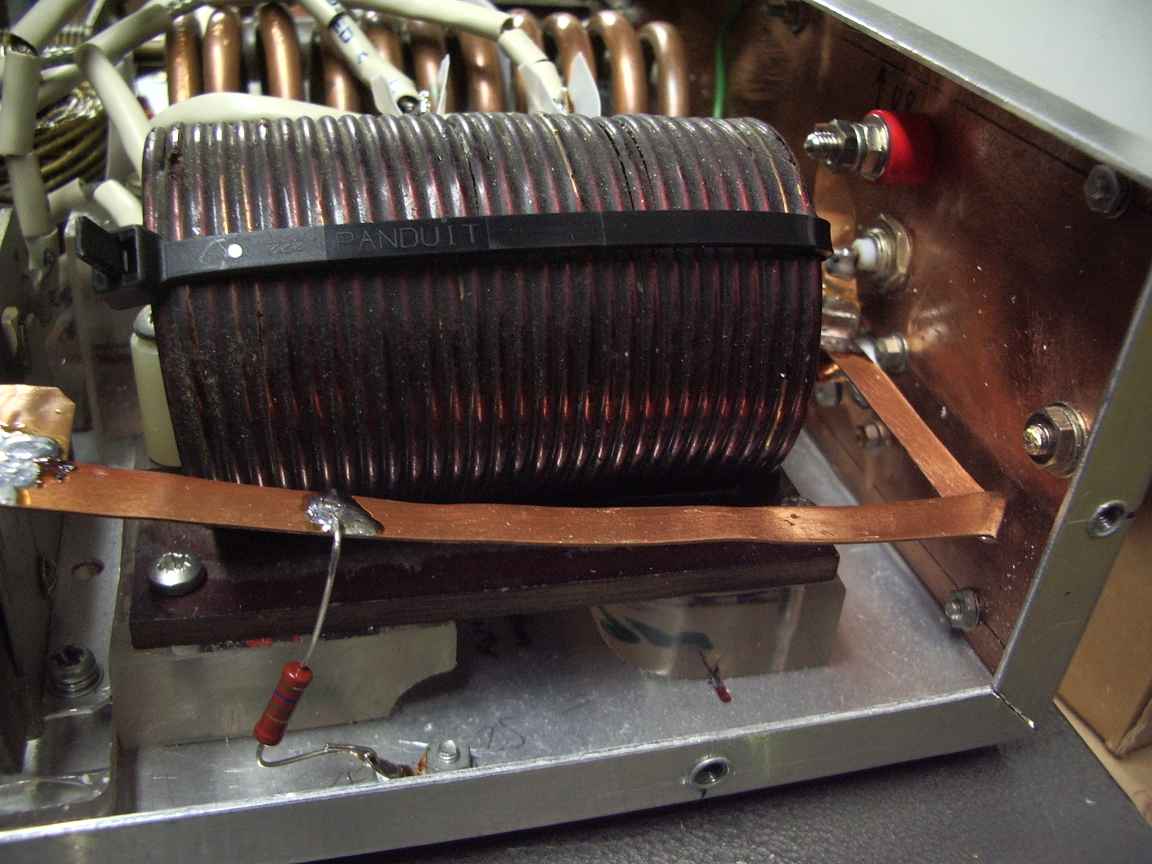

| antenna output capacitor.output strap is soldered to capacitor frame. I will take my chance with the rotor wiper | medium inductor and output strap, static drain resistor | "high" inductor |

|  |  |

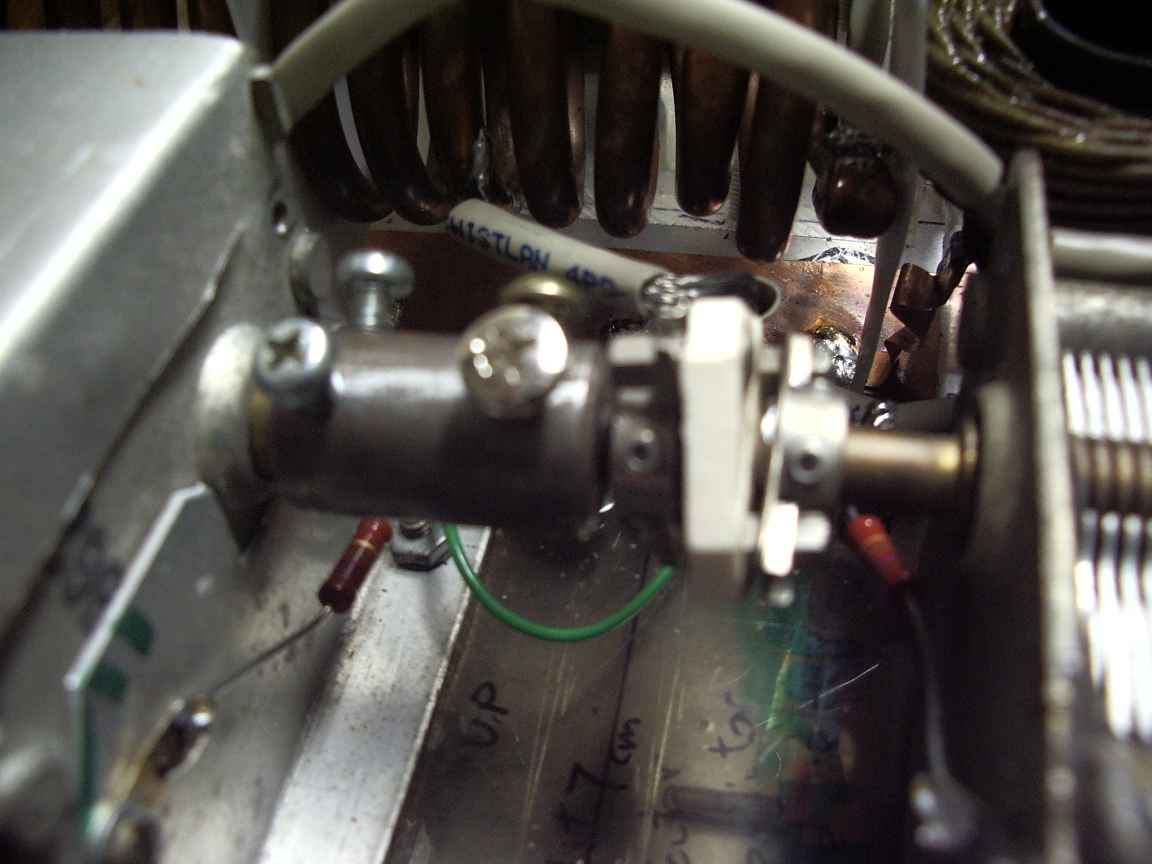

| after 60 years , a No 19 set tuning dual shaft capacitor finds a new job | homemade sharft coupler and universal joint | upper differential capacitor |

|  |  |

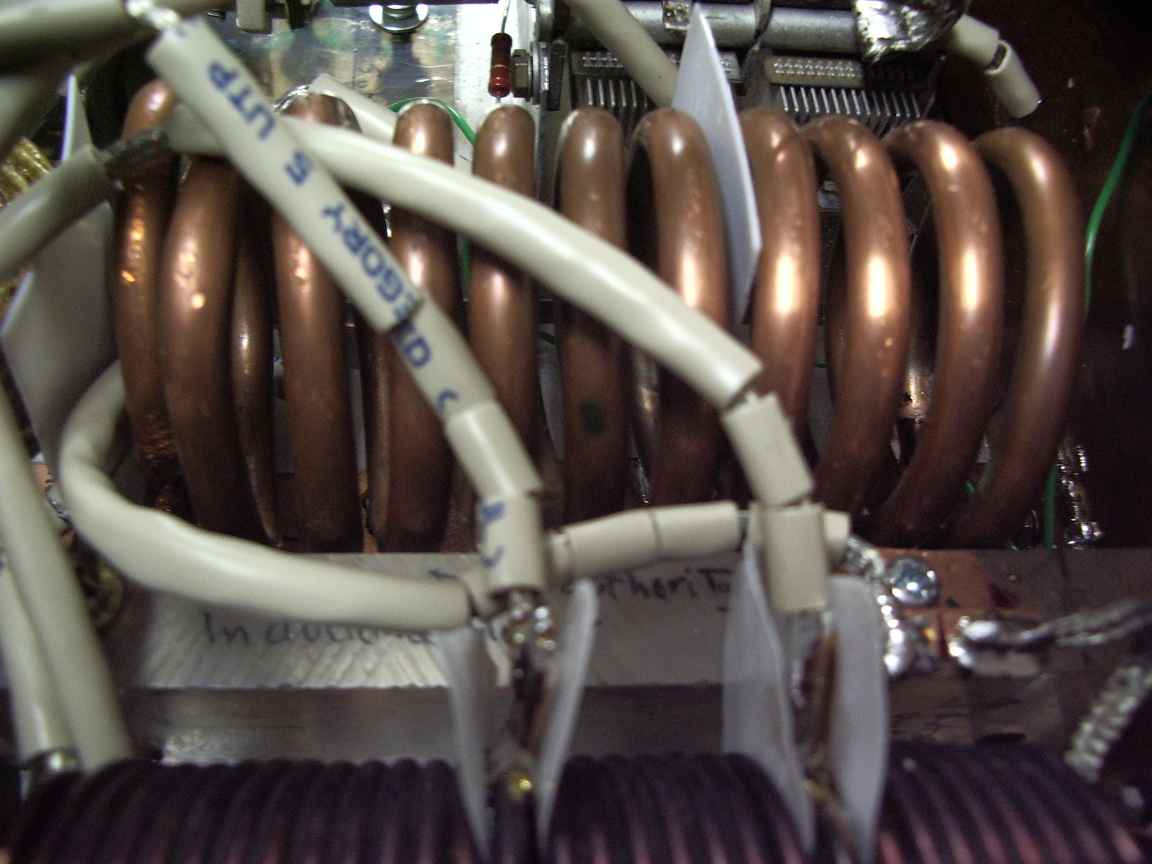

| another view of the venerable cap | heavy duty tap selector switch from an old electric blanket control | a tangle of tap conductors made from heavy RG58 braid |